Haz . 11, 2025 14:02 Listeye geri dön

Stainless Steel 304 Mesh: A Durable Solution for Diverse Industrial and Commercial Needs

In the realm of materials engineering, stainless steel mesh has emerged as a cornerstone for applications demanding strength, corrosion resistance, and versatility. Among its variants, ss304 mesh Ve wire mesh stainless 304 stand out for their exceptional properties, making them indispensable in industries ranging from construction to manufacturing. This exploration delves into the characteristics, applications, and market considerations of these materials, including factors influencing ss 304 wire mesh price, ss 304 mesh price, and insights into ss 304 wire mesh manufacturers.

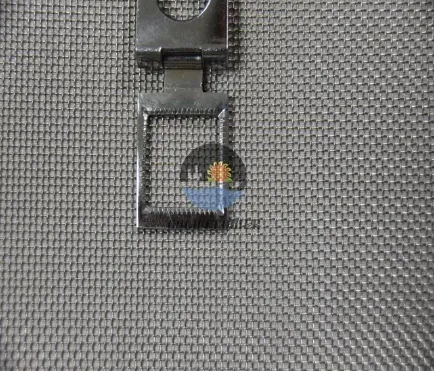

Exploring the Properties of SS304 Mesh

SS304 mesh, composed of austenitic stainless steel with a chemical composition of 18% chromium and 8% nickel, offers superior resistance to corrosion and staining. This makes it ideal for environments with high humidity, exposure to chemicals, or frequent cleaning, such as food processing facilities or coastal constructions. The mesh structure, available in various wire gauges and opening sizes, balances strength with permeability. For example, in industrial filtration systems, ss304 mesh efficiently traps particulates while allowing fluid or air to pass through, thanks to its precise weave and durable construction. Its ability to withstand temperatures up to 870°C also makes it suitable for high - heat applications, ensuring reliability in harsh conditions.

Unveiling Applications of Wire Mesh Stainless 304

Wire mesh stainless 304 finds extensive use across diverse sectors due to its adaptability. In architecture, it serves as a decorative and functional element, such as balustrades, room dividers, or facade cladding, combining aesthetic appeal with structural integrity. The food and beverage industry relies on wire mesh stainless 304 for conveyor belts, sieves, and processing filters, as its non - reactive surface meets strict hygiene standards and resists contamination. In automotive manufacturing, the mesh is used in exhaust systems and radiator guards, where its heat resistance and durability are critical. Additionally, in agricultural settings, wire mesh stainless 304 is employed for fencing and animal cages, offering long - lasting protection against the elements and wear.

Analyzing Price Factors for SS 304 Wire Mesh and SS 304 Mesh

The ss 304 wire mesh price Ve ss 304 mesh price are influenced by several key factors. Material grade and purity play a significant role, as higher - quality alloys with precise chromium - nickel ratios command a premium. Mesh specifications, including wire diameter, opening size, and weave type (e.g., plain weave, twill weave), affect production complexity and cost. For instance, a finer ss304 mesh with smaller openings requires more intricate manufacturing, leading to higher prices. Order volume also impacts costs, with bulk purchases often eligible for discounts. Additionally, surface treatments such as polishing or coatings may add to the price but enhance performance in specific environments.

Spotlighting SS 304 Wire Mesh Manufacturers

Choosing a reliable ss 304 wire mesh manufacturer is crucial for ensuring product quality and consistency. Reputable manufacturers invest in advanced weaving and finishing technologies, such as automated looms and precision cutting equipment, to deliver meshes that meet international standards like ASTM A240. They offer a range of customization options, including tailored mesh sizes, surface treatments, and packaging solutions, to cater to diverse client needs. Certifications such as ISO 9001 indicate a commitment to quality management, while export capabilities and global supply networks ensure timely delivery for international projects. When selecting a manufacturer, evaluating their experience in the industry, product testing processes, and customer feedback can help identify partners who deliver reliable wire mesh stainless 304 solutions.

FAQ: Key Insights into SS304 Mesh and Related Products

How to Select the Right SS 304 Wire Mesh Manufacturer?

When choosing a ss 304 wire mesh manufacturer, prioritize those with a proven track record in producing high - quality stainless steel products. Look for certifications that validate material composition and manufacturing processes, such as compliance with ASTM or EN standards. Request samples to assess weave consistency, surface finish, and corrosion resistance. Additionally, consider the manufacturer’s ability to provide technical support, including guidance on mesh specifications for specific applications, and their capacity to handle both small - scale orders and large - volume projects.

What Drives Variations in SS 304 Mesh Price?

Variations in ss 304 mesh price are primarily driven by material specifications, production complexity, and market demand. Finer meshes with smaller wire diameters and tighter weaves are more expensive due to the precision required in their production. Customizations, such as non - standard sizes or special surface treatments (e.g., PTFE coating for enhanced chemical resistance), can also increase costs. Market factors like fluctuations in stainless steel raw material prices and regional logistics expenses further influence the final price.

How to Maintain the Performance of Wire Mesh Stainless 304?

To prolong the lifespan of wire mesh stainless 304, regular cleaning and inspection are essential. Use mild detergents and soft brushes to remove debris or corrosive residues, avoiding abrasive tools that could scratch the surface. In highly corrosive environments, periodic rinsing with fresh water can prevent chloride accumulation, a common cause of pitting corrosion. Inspect the mesh for signs of wear, such as loose wires or deformed sections, and address any damage promptly to maintain structural integrity.

Can SS304 Mesh Be Customized for Specific Applications?

Yes, ss304 mesh is highly customizable to meet specific application requirements. Manufacturers can adjust wire gauges, mesh openings, and sheet sizes to suit filtration needs, structural loads, or aesthetic preferences. Surface treatments like electro - polishing or passivation can enhance corrosion resistance or improve appearance. For specialized uses, such as electromagnetic shielding or architectural designs, custom weaves or composite materials may be integrated into the mesh structure.

What Are the Standard Specifications for SS 304 Wire Mesh?

Standard specifications for ss 304 wire mesh include wire diameters ranging from 0.1mm to 6mm, mesh counts (threads per inch) from 2 to 200, and sheet sizes up to 3 meters in width. The most common weaves are plain weave for general use and twill weave for higher strength and durability. Material thickness and tensile strength vary based on wire gauge, with thicker wires offering greater load - bearing capacity. These specifications can be modified by manufacturers to align with the unique needs of different industries and applications.

paylaşmak

-

What Are the Key Applications and Benefits of Chicken Wire Gabion and Related Retaining Solutions?

HaberlerJul.18,2025

-

What Are the Key Advantages and Applications of PVC Coated Gabion Wire Mesh and Related Solutions?

HaberlerJul.18,2025

-

Welded Gabion Mesh Solutions: Strength and Versatility in Construction

HaberlerJul.18,2025

-

Essential Solutions for Slope Stability: A Focus on Protective Nets

HaberlerJul.18,2025

-

Durable Solutions for Erosion Control and Construction: Galvanised Gabion Systems

HaberlerJul.18,2025

-

Constructing Functional Structures: The Art of Making Gabions

HaberlerJul.18,2025