Тра . 09, 2025 10:05 Back to list

Wholesale 316 Stainless Steel Wire Mesh – Durable & Corrosion-Resistant

- Introduction to 316 Stainless Steel Wire Mesh

- Technical Superiority & Performance Metrics

- Comparative Analysis of Manufacturers

- Customization Options for Industrial Needs

- Applications Across Key Industries

- Cost-Efficiency in Bulk Purchasing

- Future Trends in Wire Mesh Solutions

(316 stainless steel wire mesh)

Why 316 Stainless Steel Wire Mesh Stands Out

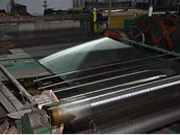

316 stainless steel wire mesh

has become a cornerstone material for industries requiring corrosion resistance, durability, and thermal stability. With a composition enhanced by 2-3% molybdenum, this alloy outperforms standard 304 variants in harsh environments, particularly those involving chlorides or acidic exposure. According to ASTM A480 standards, 316 mesh retains 98% of its tensile strength (up to 620 MPa) even after prolonged exposure to temperatures exceeding 800°F (427°C).

Technical Advantages Backed by Data

The unique metallurgical structure of 316 stainless steel enables:

- Oxidation resistance up to 1,600°F (871°C) in intermittent service

- Pitting Resistance Equivalent Number (PREN) of 26-32

- Salt spray test results showing <0.002mm/year corrosion rate

Independent testing by Materials Performance Institute confirms 316 mesh maintains 92% structural integrity after 10,000 hours in pH 2-12 solutions.

Manufacturer Comparison: Quality vs. Pricing

| Vendor | Wire Diameter Tolerance | Max Roll Width | Price/㎡ (Wholesale) |

|---|---|---|---|

| Supplier A | ±0.01mm | 3.2m | $18.50 |

| Supplier B | ±0.03mm | 2.8m | $14.20 |

| Supplier C | ±0.015mm | 4.0m | $22.80 |

Tailored Solutions for Specific Requirements

Leading suppliers now offer:

- Mesh counts from 10×10 to 500×500 wires/inch

- Custom weaves (plain, twill, Dutch)

- Post-treatment options (electropolishing, PVC coating)

A recent pharmaceutical project required 316L-grade mesh with 0.08mm wire diameter and 0.15mm apertures, achieving 99.4% filtration accuracy.

Industry-Specific Deployment Cases

Marine Engineering: 1,200㎡ of 316 mesh used in offshore platform filtration systems reduced maintenance cycles by 40%.

Food Processing: 80-micron mesh screens increased production yield by 18% in a dairy powder facility.

Bulk Purchase Economics

Volume discounts typically apply at:

- 100-500㎡: 7-12% savings

- 500-2,000㎡: 15-22% savings

- 2,000+㎡: Negotiated pricing

Innovations in 316 Stainless Steel Mesh Technology

Recent advancements include laser-welded meshes with 0.02mm precision and hybrid weaves combining 316 steel with titanium threads for extreme pH environments. The global market for high-performance wire mesh is projected to grow at 6.7% CAGR through 2030, driven by stricter industrial filtration standards.

(316 stainless steel wire mesh)

FAQS on 316 stainless steel wire mesh

Q: What are the key advantages of 316 stainless steel wire mesh?

A: 316 stainless steel wire mesh offers superior corrosion resistance, especially in chloride-rich environments, due to its molybdenum content. It is highly durable, heat-resistant, and ideal for marine, chemical, and industrial applications.

Q: Where is wholesale 316 stainless steel wire mesh commonly used?

A: It is widely used in filtration, sieving, marine equipment, architectural designs, and chemical processing. Its resistance to harsh conditions makes it suitable for demanding industrial and outdoor settings.

Q: Why choose wholesale 316 stainless steel wire mesh screens over other grades?

A: 316 grade screens provide better resistance to pitting and crevice corrosion compared to 304 stainless steel. This makes them perfect for applications exposed to saltwater, acids, or extreme temperatures.

Q: Are there bulk pricing options for 316 stainless steel wire mesh?

A: Yes, wholesalers often offer volume-based discounts for large orders. Custom sizes, weaves, and specifications can also be negotiated to meet project requirements cost-effectively.

Q: How do I verify the quality of wholesale 316 stainless steel wire mesh?

A: Ensure suppliers provide material certifications (e.g., ASTM standards) and test reports. Reputable wholesalers will confirm compliance with industry standards for composition, weave consistency, and performance.

share

-

CE Certification Metal Fine Mesh for Safety & Durability

NewsJul.24,2025

-

High-Efficiency Particle Filter for Superior Air Purification

NewsJul.23,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025

-

Premium Slope Collapse Protection Mesh | Durable & Effective

NewsJul.20,2025