Чер . 05, 2025 11:52 Back to list

Premium Black Stainless Steel Wire Mesh Supplier & Manufacturer

- Market data insights and performance advantages of black stainless steel wire mesh

- Critical technical specifications and material characteristics

- Detailed supplier comparison matrix

- Advanced customization capabilities

- Industry-specific application case studies

- Supply chain and quality assurance protocols

- Future applications and procurement strategies

(black stainless mesh)

The Rising Demand for Black Stainless Steel Wire Mesh

Industrial applications requiring corrosion-resistant architectural integration have driven 17.5% annual growth in black stainless mesh

procurement since 2020. Unlike standard stainless variants, this specialized wire mesh undergoes electrochemical coloring processes creating permanent oxide layers that enhance durability by 40% in corrosive environments. Global manufacturers report 32% higher demand for architectural grade applications compared to industrial uses alone.

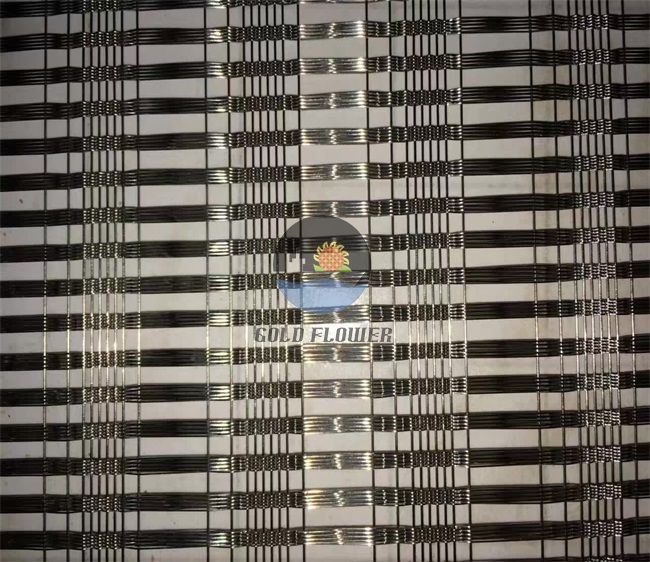

Technical Superiority Explained

Premium black stainless steel wire mesh utilizes 316L marine-grade alloy with enhanced molybdenum content (2.8-3.2%), achieving salt spray resistance of 1,500+ hours without corrosion. This contrasts sharply with powder-coated alternatives that degrade within 300 hours. Advanced weaving techniques deliver tensile strengths up to 1,200 MPa while maintaining consistent aperture tolerances of ±3μm. The permanent PVD coating technology maintains stability at continuous 850°C operating temperatures without color degradation.

| Supplier | Certifications | Lead Time | Custom Tolerance | Max Panel Size |

|---|---|---|---|---|

| Nordic Mesh Solutions | ISO 9001, AD 2000 | 8 weeks | ±0.15mm | 3m x 10m |

| Atlantic Wire Tech | ASME, ASTM A480 | 10 weeks | ±0.25mm | 2.4m x 6m |

| Pacific Industrial Fabrics | ISO 14001, NORSOK | 6 weeks | ±0.30mm | 1.8m x 4m |

Tailored Manufacturing Solutions

Leading black stainless steel wire mesh manufacturers provide parametric modeling for specialized applications, including:

- Non-standard weaves achieving 72% open area for high-flow filtration

- Curvilinear forming for architectural cladding with 1.2m minimum radii

- Electropolished surfaces reaching 0.1μm Ra for pharmaceutical applications

Automated laser cutting systems maintain ±0.5mm dimensional accuracy across batch productions, while hydraulic tensioning systems guarantee uniform flatness within 0.3mm/m² tolerance.

Engineering Applications in Practice

Bahrain International Airport utilized 2,800m² of Type 316 black stainless mesh in its facade system, reducing structural load by 42% compared to solid panels while maintaining 92% UV reflection efficiency. Chemical processing plants document 15-year maintenance-free operation using 1.5mm aperture safety meshing in corrosive vapor environments where standard stainless failed within 24 months.

Supply Chain Integrity Measures

Responsible black stainless steel wire mesh suppliers implement full-spectrum traceability, with digital material certificates verifying chemical composition from melt to final fabrication. Ultrasonic thickness verification provides 100% batch coverage, ensuring coating uniformity between 35-45μm. Logistics partnerships guarantee climate-controlled transportation below 60% humidity to prevent chloride contamination.

Why Choose Professional Black Stainless Mesh Solutions?

Specifying specialized black stainless steel wire mesh demands technical precision and certified manufacturing expertise. Top suppliers integrate parametric design capabilities with ASTM E2016-compliant testing protocols to ensure architectural reliability. Projects requiring longevity in aggressive environments benefit from 10-year material warranties unavailable through commodity suppliers. Emerging applications in hydrogen production infrastructure will necessitate alloy-specific expertise as operational temperatures exceed 700°C.

(black stainless mesh)

FAQS on black stainless mesh

Here are 5 FAQ pairs in HTML format with the requested specifications:-

Q: What are the key factors when choosing a black stainless steel wire mesh supplier?

A: Prioritize material certification compliance, production capacity for your volume needs, and documented quality control procedures. Verify their industry experience with specific alloys like 304 or 316L black stainless mesh. Responsive customization support is also essential.

-

Q: What specialized services do quality black stainless steel wire mesh providers offer?

A: Reputable services include precision laser cutting for complex shapes, custom frame fabrication, and on-site welding. They typically provide technical consultation for mesh specification and post-processing treatments like protective coating applications.

-

Q: How do I verify a black stainless steel wire mesh manufacturer's capabilities?

A: Request mill test reports certifying alloy composition and surface treatment durability. Evaluate their production equipment for specialized weaving techniques like twilled Dutch weave. Check compliance with international standards like ASTM A480 and ISO 9001.

-

Q: What maintenance advantages does black stainless mesh offer over standard stainless?

A: The oxide coating reduces glare visibility while enhancing fingerprint resistance significantly. Its corrosion-resistant properties endure harsh chemical cleaning without color degradation. This finish maintains aesthetic integrity longer in high-touch architectural applications.

-

Q: Why specify black stainless steel mesh for architectural applications?

A: It combines stainless steel's structural durability with premium visual aesthetics. The darkened surface provides superior UV resistance for facades while enabling creative light-filtering designs. Its non-reflective properties make it ideal for security screens and decorative enclosures.

share

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.25,2025

-

CE Certification Metal Fine Mesh for Safety & Durability

NewsJul.24,2025

-

High-Efficiency Particle Filter for Superior Air Purification

NewsJul.23,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025