Лис . 01, 2024 16:07 Back to list

Customizable Small Wire Mesh for Various OEM Applications and Industries

The Versatility of OEM Small Mesh Wire Mesh

In today's industrial landscape, the demand for customized solutions is rapidly increasing, and one such solution that stands out is OEM small mesh wire mesh. This product has become an essential component in various industries due to its versatility and functionality. Understanding its applications, benefits, and manufacturing processes can illuminate why it is a preferred choice for many businesses.

What is OEM Small Mesh Wire Mesh?

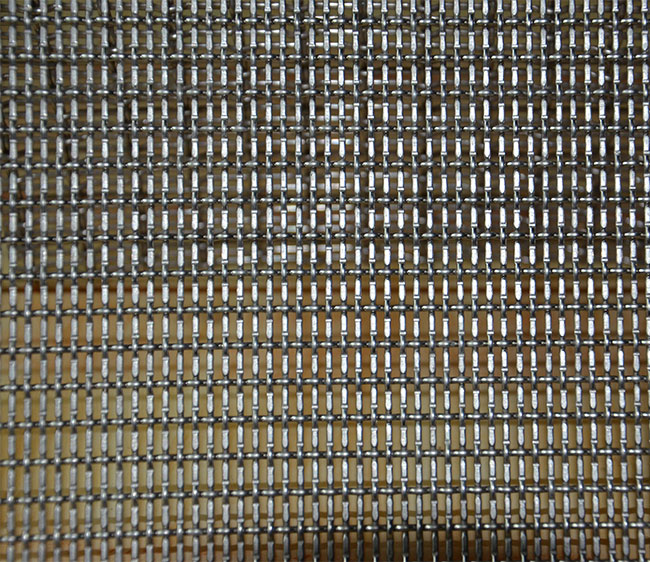

OEM stands for Original Equipment Manufacturer, which implies that the small mesh wire mesh is produced according to specific requirements set by clients. Small mesh wire mesh is characterized by its fine openings that can range from a few millimeters to fractions of an inch. This type of mesh is widely used for filtration, separation, and reinforcement purposes, tailored to fit the unique needs of different industries.

Applications in Various Industries

One of the most significant advantages of small mesh wire mesh is its versatility. It finds application in several sectors, including

1. Construction In the construction industry, small mesh wire mesh is often used for concrete reinforcement. It enhances the strength and durability of structures, ensuring they withstand environmental stresses.

2. Agriculture Farmers utilize small mesh wire mesh for various purposes, such as pest control and soil stabilization. Additionally, it can act as a barrier to prevent animals from damaging crops.

3. Food and Beverage Hygiene is paramount in the food industry, and small mesh wire mesh plays a crucial role in filtering contaminants. It is commonly found in filtration systems, ensuring that products remain safe for consumption.

oem small mesh wire mesh

4. Mining and Quarrying In mining applications, small mesh wire mesh is used in the classification of materials. Its fine openings facilitate the separation of different ores and minerals.

5. Industrial and Commercial From blenders to industrial machinery, OEM small mesh wire mesh can be found in a plethora of equipment, providing essential functionalities such as shielding, filtering, and supporting.

Benefits of Customization

Choosing OEM small mesh wire mesh means opting for a product that meets specific project needs. Manufacturers work closely with clients to understand their requirements, resulting in tailored solutions that maximize efficiency. Customization allows for variations in size, material, and coating, ensuring optimal performance in specific environments.

Manufacturing Process

The manufacturing of OEM small mesh wire mesh involves several steps, beginning with the selection of raw materials. Common materials include stainless steel, aluminum, and plastic, each chosen based on the intended use. The wire is woven or welded into a mesh configuration, followed by processes such as coating or galvanization for added protection against corrosion and wear.

Conclusion

In conclusion, OEM small mesh wire mesh stands as a testament to the power of customization in today’s manufacturing landscape. Its diverse applications across various industries showcase its essential role in ensuring efficiency and reliability. As businesses continue to seek tailored solutions, the demand for OEM small mesh wire mesh is likely to grow, establishing it as a cornerstone of modern industrial applications. Investing in high-quality, customized mesh solutions can lead to improved performance and longevity in projects, driving success across sectors.

share

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025

-

Premium Slope Collapse Protection Mesh | Durable & Effective

NewsJul.20,2025

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025