Бер . 11, 2024 14:22 Back to list

Types of Materials Used to Make Metal Mesh and Mesh Patterns

Types of Materials Used to Make Metal Mesh

Wire is the primary component of wire mesh and is produced from various ferrous and non-ferrous metals. Wire used to make wire mesh is available in a variety of gauges, which are measurements of a wire's thickness. Lower numbers in gauge numbering indicate larger wires, while higher numbers indicate thinner wires.

The wire gauge for shute or weft wires and warp wires made of plain and crimped wire is the same. The weft and warp wires of dutch weaved wire have various gauges. Very thin gauge wires that have been twisted together make up the bundles for stranded wire mesh.

The type of wire mesh and its application depend on the metals used to form it, in addition to the wire gauge. By pulling raw metal through a die or draw plate, wire for wire mesh is created. In addition to cylinder-shaped wires, rectangular, square, and hexagonal wires are also utilized to produce wire mesh.

-

Steel

Steel is an alloy of iron and carbon. Depending on the temperature, it can take either the body-centered cubic or the face-centered cubic crystalline forms (allotropic forms). Steel and cast iron have a variety of special qualities that result from the interaction of the iron allotropes with the principal carbon alloying element.

The degree to which a material may be stretched or compressed without breaking is known as the elongation (or ductility). It lies between the tensile and yield strength and is given as a percentage of the length being evaluated (i.e., what percent does the material bend before breaking). This property of steel enables it to be drawn into wires used to make metal mesh.

-

Copper Wire

Copper wire mesh has exceptional thermal and electrical conductivity and is ductile and bendable. As a result, it is frequently utilized in electrical applications and Faraday cages as a screen against radio frequency interference. Similar to how aluminum is rarely utilized in its pure form, copper is typically alloyed to improve and enhance its inherent qualities.

When copper is subjected to salt, moisture, and sunlight, its color changes from salmon-red to brownish-gray to blue-green or gray-green at the end. Copper wire mesh is coated with coatings and chemicals that either speed up or slow the oxidation process to prevent color change.

-

Bronze

Bronze is a 90% copper and 10% zinc alloy of copper. It shares several characteristics with copper, including malleability, ductility, and toughness. In addition to being tougher and less pliable than copper, bronze has stronger corrosion resistance than brass. It is utilized in industrial settings for filtering and architectural purposes.

The more common types of wire used to create wire mesh are those made of the alloys and metals mentioned above. Additionally, titanium, Hastelloy, Monel 400, nichrome, Inconel, and tungsten are utilized to create bespoke wire mesh. Basically, wire mesh can be made from any ferrous or non-ferrous metal that can be shaped into a wire.

-

Aluminum

Aluminum is inexpensive, lightweight, malleable, flexible, and resistant to corrosion. It is the most often used non-ferrous metal for making wire mesh; aluminum grade 1000, or pure aluminum, is rarely used to make aluminum wire mesh. To boost aluminum's strength and enhance some of its other features, most aluminum is alloyed with other metals like copper, magnesium, zinc, or silicon in certain amounts. The three alloys 1350, 5056, and 6061 are used most frequently to make aluminum wire mesh.

-

Brass

Brass is a copper and zinc alloy. In the production of wire mesh, it is a soft, malleable metal known as 270 yellow brass or 260 high brass. 270 yellow brass is 65% copper and 35% zinc, while the chemical make-up of 260 high brass is 70% copper and 30% zinc. Brass wire mesh has great tensile strength, excellent abrasion resistance, and is toughened due to the higher zinc content. Industrial grade brass wire mesh is a common decorative artistic element in architectural projects because of its yellow hue.

Types of Metal Mesh Patterns

The types of metal mesh patterns include:

-

Twill Weave

The twill weave pattern is perfect for weaving heavier and larger diameter wires. Warp wires are woven over and under two weft wires to create the pattern or vice versa. The warp wire is reversed at the intersections to produce a highly rigid, strong, and stable wire mesh. The pattern becomes staggered as it grows, giving the impression of parallel diagonal lines.

Wire mesh with a twill weave may filter tiny particles and support greater loads. It is a fundamental part of the manufacturing process for filters, food colanders, chemicals, shields, and mosquito nets. Due to their resistance to acids and wear, stainless steel grades 304 and 316 are used in filtration operations.

-

Crimped Wire Mesh

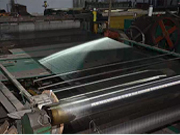

A crimping mesh machine is used to weave crimped wire mesh with a square or rectangular weave. Compressing the wire for the warp wire to wrap over the weft wire and vice versa is one of the steps used to create crimped wire mesh. The wires are bent during the crimping process, causing them to wrap around one another.

Pre-Crimp

Pre-crimped weaves are crimped before the wire is woven with the addition of tiny folds or ridges to strengthen the rigidity and strength of the wire mesh. The procedure keeps the weft and warp wires secure and stops them from shifting.

Lock Crimp

This pre-crimping technique locks the weave together at the points where the weft and warp wires connect by using the grooves left over from the crimping process. The final weave is stronger and immovable, similar to pre-crimping.

Inter-Crimp

With inter-crimp, the weft and warp wires are each given a second crimp in between the intersections. This procedure uses fine wire with wide apertures to ensure the weft and warp wires are securely locked to offer more rigidity.

-

Non-Crimped Wire Mesh

Non-crimped wire is a plain wire mesh made from a straightforward over-under weave of the weft and warp wires. The finished item has a consistent, smooth surface and a simple appearance. Traditionally, plain wire or wire that has not been crimped has a higher mesh count. The most widely used type of wire mesh is plain weave. A plain weave pattern is used in wire mesh with waves that are 3 x 3 or smaller. It is frequently employed for screening purposes, such as window and screen door screens.

-

Flat Top Weave

Flat top weave produces a strong, locking wire mesh with a flat surface using crimped weft wires and non-crimped warp wires. Since no wires protrude from the top of the mesh to wear, it has a long abrasive life. Due to its low flow resistance, flat top weave wire mesh is preferred for architectural and structural applications requiring a smooth surface. For example, vibrating screens are a typical use for flat top weaves.

-

Dutch Weave Wire Mesh

Compared to twill weave and plain weave wire mesh, dutch weave is unique. The weft wires of dutch weave wire mesh are a different diameter from the warp wires, which are coarser to provide higher tensile strength. To improve filtering efficacy, weft wires are finer and have smaller diameters. Dutch weave wire mesh is preferred as a filtering material due to its higher strength and smaller openings. Both plain and twill dutch weaving techniques have unique properties to meet the demands of various applications.

Wire mesh with a plain dutch weave has a plain dutch weave mesh that combines a plain wire weave with the dutch weave technique. The weft wire travels over and beneath the coarse warp wire using two different diameter wires, while the reverse is true for the warp wire. Its key benefits are its mechanical stability, smaller wire holes, and extraordinarily high tensile strength of plain dutch weave wire mesh.

Wire mesh with a twill dutch weave pattern combines a standard twill weave pattern with a dutch weave pattern. The weft wire forms a thin mesh in the direction of the warp wire by passing over and under two warp wires alternately, while the warp wires make a coarser mesh in the same weave. Due to its ability to sustain larger loads for filtering purposes and finer apertures than regular twill weave, twill dutch weave is preferable.

Dutch woven wire mesh in reverse is identical to dutch woven wire mesh in plain form. However, with the warp and weft wires switched, the two weaves differ in how the weft and warp are woven. The warp wires have more strength because they are tightly woven with heavier weft wires and positioned close together. Applications requiring wire mesh with acoustic characteristics, mechanical strength, and throughput filtration use the reverse dutch weave.

-

Metal Mesh Edges

Wire mesh edges come in two different varieties: raw and selvage. The weft wires provide an edge along the length of the roll when weaving wire mesh cloth, preventing the mesh from unraveling. These weft wires are exposed at the edge of the wire mesh in the case of a raw edge.

To strengthen the stability of the mesh and safeguard workers when handling the mesh, selvage edge wire mesh has a completed border. There are several ways to make selvage edges, one of which is to loop the wires at the cloth's edge.

share

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025

-

Simple Style Decorative Mesh for Modern Spaces ODM Stainless Steel Decorative Mesh Supplier

NewsJul.06,2025

-

High-Performance Filter Cartridge – Apex RF 1050 Alkaline, Resin Bonded & Jacuzzi Pool Filter Options

NewsJul.06,2025

-

10x24x1 Air Filter - High Efficiency Replacement for Clean Air Air Compressor & Conditioner Compatible

NewsJul.05,2025