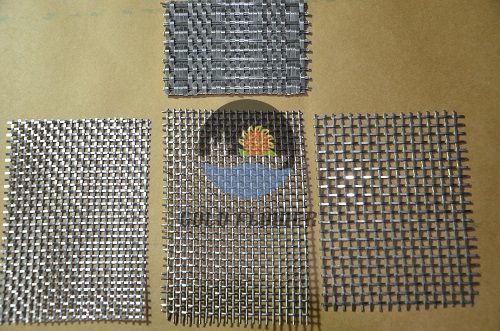

304 316 Crimped Wire Mesh

Crimped Wire Mesh

Crimped wire mesh is made by a crimping process from metal wires (carbon steel wire, stainless steel wire, galvanized steel wire) ranging from 1.5 mm to 6 mm in diameter. It is commonly used in vibrating screens, windows, partitions, grills, mining screens and other screen applications that require mesh size. We supply different types of wire mesh, such as brass wire mesh, Dutch woven wire mesh, etc.

Specification of embossed wire mesh

Material: metal wire mesh - carbon steel wire, stainless steel wire, galvanized steel wire

Features: mesh with very precise and consistent openings, corrosion and acid and alkali resistant, sturdy construction

Applications: protective mesh, fencing, barbecue mesh, coal screening, etc.

| Hole size(mm) | Wire diameter(mm) | Hole size(mm) | Wire diameter(mm) |

| 3-5 | 0.8 | 2.3 | 11.5×4 |

| 2-10 | 1 | 2 | 10×3.5 |

| 2-12 | 1.2 | 1.8 | 9×3 |

| 5-30 | 2 | 1.6 | 8×2.5 |

| 5-30 | 2.5 | 1.4 | 7×2 |

| 5 | 1.2 | 1.2 | 5.5×1.5 |

| 5 | 2 | 1.0 | 4.5×1.2 |

| 4 | 19×9 | 0.8 | 4×1 |

| 3.5 | 18×8 | 0.7 | 3.5×0.9 |

| 3.2 | 16×7 | 0.6 | 3.3×0.7 |

| 2.9 | 15×6 | 0.5 | 2.7×0.6 |

| 2.6 | 13.5×5 | 0.3 | 1.5×0.3 |

304 Crimped wire mesh features

1. Safety protection: Reject unsafe factors to prevent damage or invasion of animals such as rats, snakes, flies and mosquitoes.

2. Prevention of falling objects: The old people in the living room or the children playing in the house will not be in an unsafe state because of the opening of the doors and windows.

3. Invisible and transparent: no barrier, no occlusion, no feeling of depression, indoors to keep bright and natural at any time.

4. Easy to open for easy escape: instead of the traditional fixed fence, family members can easily escape from the scene in the event of a fire.

5. Energy saving: no air blockage, indoor air breeze at any time, reducing unnecessary air conditioning operation.

6. Easy to care: Dust and oil are easy to clean, and it is as bright as a vacuum cleaner, absorbent sponge or ordinary brush.

7. Resist UV: Resist UV rays up to 30%, so you can avoid the damage of UV rays to the skin while enjoying the sun.

8. The mesh surface is hard and flat, the mesh is even.

9. The electrostatic powder coating treatment Anti-aging Anti-corrosion.

Crimped metal wire mesh usage

1. Organs, units with higher safety levels - bulletproof

2. Office building, villa, community - anti-theft

3. Mountainous areas with more mosquitoes, wilderness, suburbs - anti-mosquito

4. Unified management, residents or business districts - - Beautiful

5. Wet or dry city - corrosion and exposure.

4 types of crimped process forms

Double rolled edge

Both warp and weft wires are directly woven with straight metal wires. Mainly used for lighter wires to ensure the tension of the wire mesh

Flat top crimp

Made of round and shaped plain weave. All mesh nodes are underneath. Characterized by very heavy and durable construction.

Intermediate crimp

Intermediate crimps can be divided into single intermediate crimps and double intermediate crimps.

Single intermediate crimp means that the weft threads are pre-curled and the warp threads are directly woven. Double intermediate crimp means that both the weft and warp threads are pre-curled and then woven together.

Locked edge crimp

Locks the wires in their position by pressing on each side of the raised wires. This construction of crimped woven wire is more stable. Welcome to contact us!

-

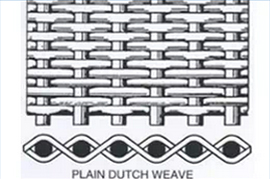

Plain dutch weave

-

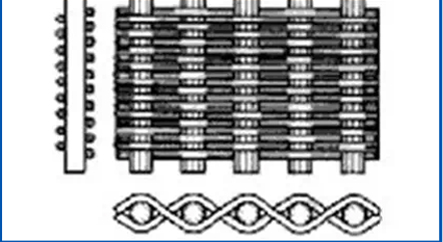

Twilled dutch weave

-

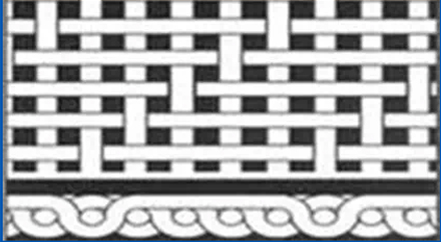

Reverse dutch waeve 1

-

Reverse dutch weave 2

-

Five-heddle weave

-

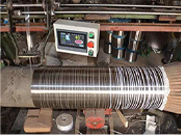

Material Production

-

Diameter Inspect

-

Tension Test

-

Material Check

-

Material Check

-

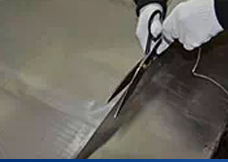

Trimming Edge

-

Length and Width Inspect

-

Hole Size Test

-

Mesh Inspect

-

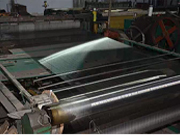

Weaving

-

Intension Test

-

Diameter Inspect

-

Thickness Inspect

-

Role size Inspect

-

Mesh Test

-

Length and Width Check

-

Trimming Edge

-

Mesh Inspect

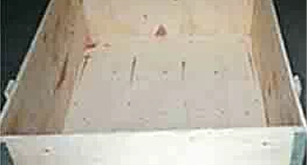

With the most perfect way to protect your cargo security

-

1

Cardboard Tube

-

2

Thick Paper Board

-

3

Thick Plastic Cloth

-

4

Perfect Wooden Case

-

5

Thick Plastic Bubble Film

-

6

Excellent Cover

-

7

Steel Strap Fix

-

8

Package Check

-

9

Container Transport