Ліст . 18, 2024 23:58 Back to list

CE Certification for Wire Grating Applications and Standards in Industrial Use

Understanding CE Certification for Wire Grating

Wire grating, commonly used in various industrial applications, plays a crucial role in structural support and safety systems. As industries become increasingly globalized, ensuring that products meet international safety and quality standards is essential. One of the most recognized certifications is the CE certification. This designation indicates that a product complies with the necessary European health, safety, and environmental protection standards.

What is CE Certification?

CE marking is a certification mark that indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). The term CE stands for Conformité Européenne, which means European Conformity in French. For wire grating manufacturers, obtaining a CE certification means that their products have been rigorously tested and meet the essential requirements laid down by the relevant European directives.

Importance of CE Certification for Wire Grating

In industries such as construction, manufacturing, and transportation, wire grating is often integral to platforms, walking surfaces, and safety barriers. The strength and reliability of wire grating are vital to preventing accidents and ensuring worker safety. CE certification provides assurance to customers that the wire grating meets established guidelines, thereby enhancing marketability and credibility.

Moreover, CE marking facilitates trade between countries within the EEA. When wire grating is CE certified, it can be sold freely across member countries without the need for additional testing or certification, making it easier for manufacturers to expand their market reach.

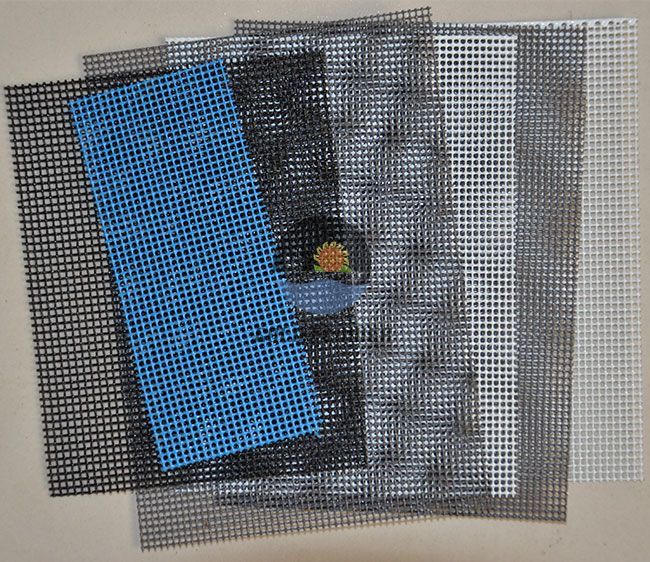

ce certification wire grating

The Certification Process

Achieving CE certification involves several steps. Initially, manufacturers must identify the applicable directives and standards relevant to their products. For wire grating, this might include standards related to load-bearing capacity, slip resistance, and fire safety.

Once the specific standards have been identified, the manufacturer must conduct rigorous testing, often using third-party laboratories, to ensure compliance. This process may involve both mechanical testing and inspection of the production process. After successful evaluations, the manufacturer can compile a technical dossier, demonstrating conformity and keeping documentation for at least ten years.

Finally, the manufacturer must affix the CE mark to their products, accompanied by a declaration of conformity stating that they meet the required standards. It is crucial that manufacturers stay updated on any changes in regulations that may affect their products post-certification.

Benefits Beyond Compliance

Beyond simply meeting legal requirements, CE certification offers several other advantages. It benefits manufacturers by enhancing product quality and consistency, reducing risk of recalls and liability issues. For customers, it provides confidence in product safety and reliability, fostering a stronger relationship between consumers and manufacturers.

In conclusion, CE certification is vital for wire grating manufacturers looking to access European markets and ensure that their products adhere to stringent safety and quality standards. As industries continue to evolve, maintaining compliance through CE certification will remain a key factor in ensuring product integrity and enhancing consumer trust.

share

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025