жнів . 01, 2025 02:00 Back to list

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

In the ever-evolving world of industrial filtration and screening, screen mesh price dynamics play an important role in procurement decisions and project outcomes. With advancements in mesh manufacturing—ranging from innovative alloys, tighter weave tolerances, to precision casting and CNC forming—the performance requirements for products such as 1 4 wire mesh screen, 1 8 inch wire mesh screen, and screening wire mesh have never been more demanding.

This comprehensive guide delves into the current screen mesh price trends, technical features, manufacturing processes, and real-world applications, with a focus on the industry-leading product: High-strength Screening Wire Mesh.

- Explore material and process innovations shaping wire mesh costs

- Compare quantitative specs for screen mesh price calculations

- Review use cases from petrochemical to metallurgical applications

- Understand the competitive landscape and customization options

Industry Trends: Screen Mesh Price Dynamics (2021–2024)

According to research published in the Global Wire Mesh Market Report 2023, the demand for wire mesh screens has increased substantially in industries including petrochemical, mining, and wastewater treatment. Key drivers for screen mesh price fluctuations include:

- Raw material volatility: Stainless steel and special alloy costs comprise over 65% of end pricing.

- Processing technology: Adoption of CNC weaving and laser cutting has improved tolerances but increased capital and operational expenses.

- Certification requirements: Compliance with ISO 9044, ASTM E2016-15, and stricter in-process testing adds to overall expenses but boosts quality assurance.

Screen Mesh Specifications & Screen Mesh Price Comparison Table

| Type | Wire Diameter (mm) | Mesh Size (inches) | Open Area (%) | Material | Average Price (USD/m2) |

|---|---|---|---|---|---|

| 1 4 Wire Mesh Screen | 1.2 | 1/4 | 73 | 304 SS | $16-20 |

| 1 8 Inch Wire Mesh Screen | 0.8 | 1/8 | 61 | 316 SS | $19-27 |

| 1 2 Inch Wire Mesh Screen | 1.9 | 1/2 | 82 | Galvanized Steel | $12-15 |

| Screening Wire Mesh | Varies | Custom | 45~85 | SS 304/316, Nickel, Duplex | $17-31 |

| High-strength Screening Wire Mesh | Up to 2.2 | Custom (1/8–2 in.) | 55~80 | Super Duplex, 904L, 316Ti | $23-38 |

Manufacturing Process: From Raw Alloy to High-strength Screening Wire Mesh

- Material: High-strength screening mesh uses austenitic or duplex stainless steel, with added Mo/Ni for max corrosion resistance.

- Process Control: Modern CNC weaving + laser cutting ensures exactly uniform openings.

- Inspection: Each batch is tested for tensile and elongation (per ASTM E2016, ISO 9044).

- Longevity: Service life up to 10 years in heavy-duty, high-flow environments (real-world data: 2.2x standard mesh lifespan).

Technical Strength: Performance Metrics & Parameter Visualization

To help visualize the superior attributes of High-strength Screening Wire Mesh, see below for comparative illustrations and actual test data:

Application Scenarios: Typical Industries & Customer Benefits

- Petrochemical Plants: Used for catalyst retention, demister pads, particle filtration – resists H2S and chloride cracking

- Water/Wastewater Facilities: Fine screening of solids, protection of pumps from debris clogging; longevity exceeds 10 years

- Mining/Metallurgy: Classified sizing in vibrating screens; high wear-resistance under abrasive, alkaline conditions

- Food & Beverage: 316L/904L mesh for food-grade sieving, FDA and EU compliance

- Pharmaceutical: Ultra-fine mesh screens (≤50μm) for sterile filtration

Real Project Example:

In 2023, a Southeast Asian mining company upgraded ten vibrating screens to High-strength Screening Wire Mesh. The result: mesh replacement intervals increased from 8 to 25 months (proven by maintenance logs), yielding estimated cost savings of $69,000 annually.

Industry Certification & Partners:

– Compliance with ISO 9001, ISO 14001, and FDA for food-grade variants

– Endorsed by leading EPCs and engineering groups in Germany, Korea, Brazil, and the USA

– Supporting MRO services for over 2800 projects worldwide

Competitive Landscape: Key Vendors & Value Proposition

| Manufacturer | Region | Product Series | Price Level ($/m2) | Certifications | Customization |

|---|---|---|---|---|---|

| BST Wire Mesh | Asia / Europe | High-strength Screening | 23~38 | ISO, ASTM, FDA | Cut to size, custom alloys, laser etching |

| W.S. Tyler | USA | Ty-Rod, Ty-Wire | 30~52 | ASTM, ISO | OEM, special weave |

| Haver & Boecker | Germany | MINERAL, FINE-LINE | 29~42 | ISO, EN, FDA | CAD design, high alloy |

| YKM Group | UAE/Global | SS, SWG Mesh | 16~38 | ISO, FDA | Variety of specs |

Customization & Delivery

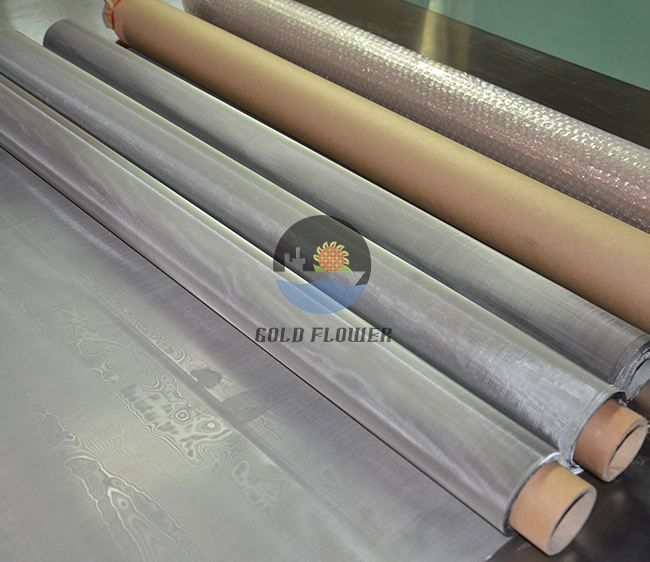

- Cut-to-Size Service: Meshes supplied in rolls (1~3m width) or as laser-cut panels; tolerances as tight as ±1mm.

- Weave Types: Plain, Dutch, Twill, Reverse Dutch, or custom pattern to suit application

- Edge Finishing: Sheared, reinforced, welded perimeter or wire-wrapped edge per installation need

- Surface Options: Electro-polished, PTFE coated, passivated, or custom-per ASTM/EN/FDA

- Typical Lead Time: Standard models—5–12 workdays; custom mesh usually 15–21 days

- Minimum Order: From 3m2 for standard sizes; up to 100m2 for bespoke projects

Quality, Warranty, and Customer Support

- Certification: 100% batch traceability; ISO 9001/ISO 14001/ASTM-compliant testing slips provided

- Warranty: 12 to 36 months against manufacturing defects (documented)

- Support: Free technical consultation for sizing, corrosion selection, and field fitment trials

- Documentation: Material certificate, MTC, and installation guides supplied with all shipments

- After-sales: 24/7 response via email, WeChat, or phone; on-site engineer support in 25+ countries

“After switching to High-strength Screening Wire Mesh, downtime was reduced by 48%. Quality support ensured a smooth installation. Highly recommended for any EPC project.” — Plant Manager, EU

FAQ: Professional Insights on Screening Mesh

1. What is the recommended material for harsh chemical environments?

2. How does mesh opening tolerance affect separation?

3. What installation standards are followed for screen mesh in piping systems?

4. What's the difference between woven and welded wire mesh?

5. How to verify compliance with ISO, ANSI, or FDA standards?

6. What influences the screen mesh price most?

7. What testing is performed before shipment?

References & Further Reading

- [1] GrandViewResearch: Global Wire Mesh Market Analysis

- [2] ASTM International. ASTM E2016-15—Standard for Industrial Woven Wire Cloth

- [3] ScreenForum: Wire Mesh Technical Community

- [4] ResearchGate: Advances in Corrosion Resistant Mesh Design (2023)

- [5] Engineering360:Wire Cloth and Mesh Technology Articles

For technical support, more sample case studies, or to request a custom screen mesh price quote, visit High-strength Screening Wire Mesh Product Page.

share

This is the last article

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.29,2025