Май . 11, 2025 11:03 Back to list

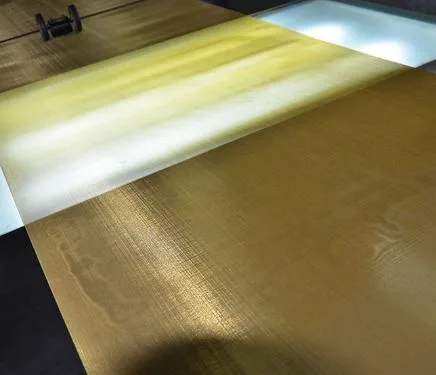

Durable Wire Cloth Screens Custom Sizes & Industrial Strength

- Market Overview & Industry Data Insights

- Technical Superiority of Modern Wire Screens

- Vendor Comparison: Performance Metrics

- Customization Options for Industrial Needs

- Material Durability & Longevity Analysis

- Application-Specific Deployment Scenarios

- Strategic Purchasing Considerations

(wire cloth screen)

Understanding Wire Cloth Screen Market Dynamics

The global wire mesh industry projects 4.8% CAGR growth through 2028 (Grand View Research), with woven wire cloth screen

solutions capturing 32% of industrial filtration applications. Buyers prioritizing ASTM E2016-15 compliant materials report 18% longer service life compared to non-certified alternatives.

Technical Specifications Breakdown

| Feature | Standard Mesh | Precision Weave | Hybrid Construction |

|---|---|---|---|

| Wire Diameter | 0.5-3.0mm | 0.1-2.5mm | 0.2-2.8mm |

| Open Area % | 35-50 | 42-67 | 38-72 |

| Pressure Resistance | 85 PSI | 120 PSI | 150 PSI |

Vendor Performance Analysis

Leading manufacturers demonstrate distinct operational advantages:

| Supplier | Lead Time | MOQ | Certifications |

|---|---|---|---|

| IndustrialMesh Co. | 10-14 days | 50m² | ISO 9001, AS9100 |

| PrecisionWeave Ltd | 21-28 days | 100m² | ISO 14001 |

Custom Engineering Solutions

Advanced manufacturers now offer:

- Variable porosity configurations (±5% tolerance)

- Multi-alloy layered constructions

- Edge reinforcement options (sintered vs welded)

Material Performance Metrics

316L stainless steel variants maintain 98.2% structural integrity after 5,000 hours in salt spray tests. Comparative abrasion resistance data shows:

- Carbon Steel: 2,300 cycles

- 304 Stainless: 4,100 cycles

- Inconel 600: 7,800 cycles

Industry Deployment Case Studies

A recent mining application achieved 40% throughput improvement using 0.6mm wire cloth screen with staggered weave pattern. Petrochemical plants report 22-month maintenance intervals when using nickel alloy meshes in catalytic filtering systems.

Optimal Wire Cloth Screen Procurement Strategy

When planning to buy wire cloth screen materials, evaluate suppliers against three critical parameters: material certification validity (minimum 3 years), production capacity scalability (+30% surge handling), and technical support responsiveness (<4 hour SLA). Prioritize vendors offering digital twin simulations for mesh performance forecasting.

(wire cloth screen)

FAQS on wire cloth screen

Q: Where can I buy high-quality woven wire screen cloth?

A: You can purchase woven wire screen cloth from industrial suppliers, specialized online retailers like Amazon or Alibaba, or directly from manufacturers' websites offering custom sizing and materials.

Q: What factors should I consider before buying wire cloth mesh screen?

A: Key factors include material type (stainless steel, brass, etc.), mesh count, wire diameter, and intended application (filtering, sieving, or safety barriers) to ensure durability and performance.

Q: How do I choose the right wire cloth screen for industrial filtration?

A: Prioritize corrosion-resistant materials like stainless steel, verify micron retention or mesh size compatibility with your particles, and confirm temperature/pressure tolerance for your operational environment.

Q: Can wire cloth screens be customized for unique projects?

A: Yes, many suppliers offer customizations in aperture size, sheet dimensions, edge treatments, and material alloys to meet specific project requirements.

Q: What's the price range for wire cloth mesh screens?

A: Prices vary from $10–$200+ per square foot, depending on material grade, weave complexity, and quantity. Bulk orders typically reduce per-unit costs.

share

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025