aug . 24, 2025 01:20 Back to list

Premium CE Certified Metal Fine Mesh for Precision & Safety

The Imperative of CE Certification for Advanced Metal Fine Mesh Solutions

In the demanding landscape of industrial applications, the integrity and performance of filtration, separation, and structural components are paramount. This is particularly true for specialized materials like ce certification metal fine mesh, which serves critical functions across diverse sectors. CE certification signifies compliance with European Union health, safety, and environmental protection standards, assuring end-users of product reliability and suitability for regulated markets. This article delves into the technical intricacies, manufacturing processes, and strategic importance of CE-certified metal fine mesh products, including ce certification metal screen fabric and ce certification hard metal mesh, for B2B stakeholders.

The increasing complexity of industrial processes necessitates materials that not only meet stringent operational demands but also adhere to international regulatory frameworks. Fine metal meshes, whether ce certification architectural metal mesh fabric for aesthetic and functional designs or ce certification galvanized metal wire mesh for enhanced durability in harsh environments, are integral to modern engineering. Understanding their technical parameters, application versatility, and the robust manufacturing behind them is crucial for informed procurement and successful project execution.

Current Industry Trends and Market Drivers

The global market for advanced metal mesh products is experiencing significant growth, driven by several key trends. Automation in manufacturing, the escalating demand for high-purity filtration in pharmaceuticals and food & beverage, and the expansion of renewable energy infrastructure are pushing the boundaries of material science and mesh design. There is a discernible shift towards materials offering superior corrosion resistance, enhanced tensile strength, and optimized flow dynamics, often encapsulated in products such as ce certification black metal wire mesh for specialized screening or ce certification thick metal mesh for heavy-duty support.

Sustainability initiatives are also influencing material selection, favoring alloys with extended service life and recyclability. Furthermore, the integration of smart technologies into industrial equipment demands precision-engineered components, making the reliable performance of ce certification wire metal and similar products indispensable. End-users are increasingly seeking customized solutions that provide not only functional excellence but also compliance with international safety and quality standards, with CE certification being a primary indicator of such adherence for the European market and beyond.

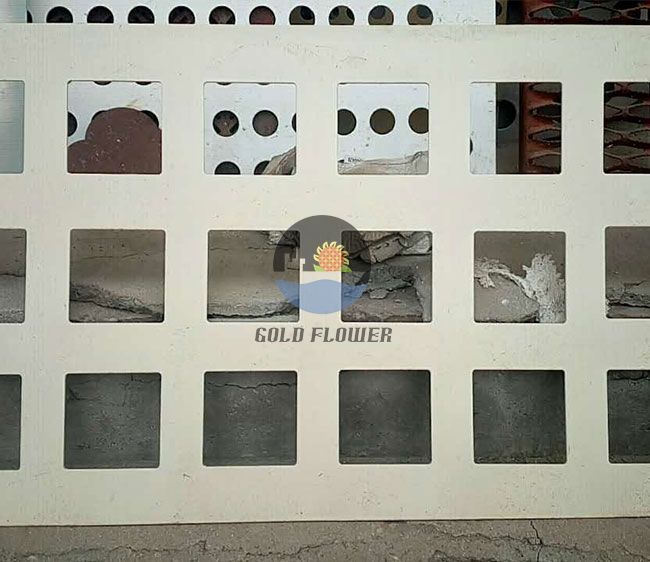

Illustrative example of precision-engineered metal mesh components.

Manufacturing Process of CE Certified Metal Fine Mesh

The production of high-quality, ce certification metal fine mesh involves a meticulously controlled multi-stage process, ensuring both material integrity and precise geometric configurations. This systematic approach is crucial for achieving the consistent performance required in demanding industrial environments.

1. Material Selection and Preparation

- Raw Material Sourcing: Selection of high-grade metals such as stainless steel (304, 316, 316L for corrosion resistance), inconel, monel, hastelloy, titanium, or aluminum alloys, based on specific application requirements (e.g., chemical compatibility, temperature resistance). All raw materials are procured from certified suppliers and undergo initial quality checks to meet ISO 9001 standards.

- Wire Drawing/Sheet Preparation: For woven meshes, raw wire coils are drawn to precise diameters. For perforated meshes, metal sheets are prepared to exact thickness and dimensions. This stage utilizes advanced machinery to ensure uniformity and minimize material imperfections.

2. Mesh Formation Techniques

- Weaving (for Woven Mesh): Precision looms interlace warp and weft wires to create the desired mesh count and weave pattern (plain, twill, Dutch weave). This mechanical process is optimized for minimal wire damage and consistent aperture size, critical for filtration efficiency.

- Perforation (for Perforated Metal): Using CNC punching machines or laser cutting technology, holes of various shapes (round, square, slotted, ornamental) and sizes are created in metal sheets. CNC machining ensures extreme precision and repeatability, vital for `other shapes perforated metal sheet` products.

- Expanded Metal Formation: A continuous sheet is simultaneously slit and stretched, creating diamond-shaped openings. This method yields a strong, lightweight mesh with no welds or interlocks.

3. Finishing and Treatment

- Cleaning and Degreasing: Removal of oils, greases, and contaminants from the mesh surface.

- Edge Treatment: Shearing, slitting, or calendering to achieve desired dimensions and eliminate sharp edges, ensuring safe handling and integration.

- Surface Treatments: This can include passivation for stainless steel (enhancing corrosion resistance), powder coating (for ce certification black metal wire mesh or aesthetic finishes), or galvanization (for ce certification galvanized metal wire mesh to provide sacrificial protection).

- Heat Treatment: Annealing or stress relieving processes may be applied to optimize mechanical properties and relieve internal stresses.

4. Quality Control and Testing

- Dimensional Inspection: Verification of mesh count, wire diameter, hole size, sheet thickness, and overall dimensions using precision calipers, micrometers, and optical comparators.

- Material Composition Analysis: Spectrographic analysis to confirm alloy composition, ensuring compliance with material specifications.

- Performance Testing: Depending on application, this may include flow rate testing, pressure drop analysis, tensile strength tests (to ASTM E8 standards), and corrosion resistance tests (e.g., salt spray testing to ASTM B117).

- CE Marking Compliance: Rigorous documentation and testing against relevant CE directives (e.g., Machinery Directive 2006/42/EC, Low Voltage Directive 2014/35/EU if applicable, or harmonized standards like EN 10025 for structural steel). This final step confirms the product, like a ce certification architectural metal mesh fabric, meets all essential health and safety requirements for sale within the EEA.

5. Packaging and Logistics

Proper packaging ensures the pristine condition of the ce certification metal fine mesh during transit. Solutions range from wooden crates for heavy-duty sheets to customized rolls for flexible meshes, all designed to prevent damage and contamination.

This comprehensive process flow underpins the superior quality and reliability of CE-certified metal fine mesh products, making them suitable for critical applications requiring extended service life and robust performance. Target industries often include petrochemicals (filtration), metallurgy (screening), water supply & drainage (debris removal), and chemical processing (separation), where advantages like energy saving through efficient filtration and exceptional corrosion resistance are highly valued.

Technical Specifications and Parameters of Metal Fine Mesh

The performance of ce certification metal fine mesh is fundamentally defined by its technical specifications. These parameters dictate suitability for specific applications and ensure optimal operational efficiency. Below is a comprehensive overview of key parameters and typical ranges for high-grade industrial meshes.

Key Product Specifications Table

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Material Grade | Common alloys for strength and corrosion resistance. | Stainless Steel (304, 316, 316L), Inconel, Monel, Hastelloy, Titanium, Aluminum |

| Mesh Count (Woven) | Number of openings per linear inch (or cm) in both warp and weft directions. | 10 to 635 mesh (or finer for specialized applications) |

| Wire Diameter | Diameter of individual wires used in woven mesh. | 0.02 mm to 2.0 mm (0.0008" to 0.0787") |

| Aperture Size | Clear opening between adjacent wires. | 1 micron to 2.0 mm |

| Open Area | Percentage of total mesh area that is open for flow. | Typically 20% to 70% (varies greatly by mesh type and application) |

| Sheet Thickness (Perforated) | Gauge of the metal sheet for perforated products. | 0.5 mm to 10 mm (0.02" to 0.4") |

| Hole Diameter (Perforated) | Size of perforations in perforated metal. | 0.5 mm to 50 mm (0.02" to 2") |

| Weave Type (Woven) | Pattern of wire interweaving. | Plain, Twill, Dutch (Plain/Twill), Reverse Dutch |

| Corrosion Resistance | Ability to withstand degradation from chemical exposure. | Excellent (316L SS, Hastelloy), Good (304 SS) |

| Temperature Rating | Maximum operating temperature. | Up to 1100°C (depending on material, e.g., Inconel) |

These specifications ensure that a product like ce certification metal fine mesh is precisely matched to the operational demands, whether it's for high-temperature applications requiring ce certification hard metal mesh or fine-particle separation using ce certification fine metal mesh netting.

Technical Advantages of CE Certified Metal Fine Mesh

- Superior Filtration Efficiency: Precision manufacturing of ce certification metal fine mesh ensures uniform aperture sizes, leading to highly effective particle retention and separation. This translates to purer end-products and reduced downstream equipment wear.

- Exceptional Durability and Longevity: Constructed from robust materials like stainless steel, these meshes exhibit high resistance to abrasion, impact, and fatigue. This extends the service life, minimizing replacement costs and downtime.

- Corrosion and Chemical Resistance: Utilizing materials such as 316L stainless steel, Hastelloy, or Titanium, CE-certified meshes can withstand aggressive chemical environments, high temperatures, and corrosive media, making them ideal for petrochemical and chemical processing industries.

- High Temperature and Pressure Resilience: Engineered to maintain structural integrity under extreme conditions, these meshes are suitable for high-temperature furnaces, pressure vessels, and demanding industrial reactors.

- Ease of Cleaning and Maintenance: The smooth surface finishes and material properties of many metal meshes facilitate easy cleaning, often allowing for backwashing or ultrasonic cleaning, which contributes to energy saving by maintaining optimal flow rates.

- Enhanced Structural Integrity: Even ce certification fine metal mesh netting maintains considerable tensile strength and dimensional stability, crucial for applications involving mechanical stress or dynamic loads.

- Regulatory Compliance: The CE mark assures compliance with stringent EU directives, reducing regulatory risks and facilitating market access for products and components incorporating these meshes.

Demonstration of metal mesh flexibility and structural integrity.

Application Scenarios and Target Industries

The versatility of ce certification metal fine mesh makes it an indispensable component across a multitude of industries. Its ability to perform under extreme conditions and provide precise separation is key to its widespread adoption.

- Petrochemical and Chemical Processing: Used in catalyst support, molecular sieves, filtration of corrosive liquids and gases, and as internal components in reactors and distillation columns. Applications benefit from corrosion resistance and thermal stability.

- Water Treatment and Wastewater Management: Filtration of suspended solids, pre-filtration for reverse osmosis, and media support in biological reactors. Longevity and resistance to fouling are critical.

- Pharmaceuticals and Food & Beverage: Precision sieving, clarification of liquids, sterilization filters, and sifting ingredients. Hygienic design and material purity are paramount, often requiring 316L stainless steel.

- Mining and Metallurgy: Screening of aggregates, ore processing, and fluid bed dryers. ce certification hard metal mesh is particularly suited for abrasive conditions.

- Architecture and Design: ce certification architectural metal mesh fabric is used for facades, balustrades, sunscreens, and interior design elements, offering both aesthetic appeal and functional benefits like ventilation and light diffusion.

- Automotive and Aerospace: Fuel filters, air filters, EMI shielding, and acoustic panels. Lightweight and high-strength alloys like ce certification aluminum metal mesh fabric are often preferred.

- Electronics: EMI/RFI shielding, battery electrodes, and heat dissipation components. Fine meshes provide crucial protection and functionality.

- Energy Sector: Filter elements in oil and gas extraction, nuclear power plant components (e.g., cooling systems), and support grids in renewable energy systems (e.g., biomass gasification).

Vendor Comparison: Key Differentiators for Metal Fine Mesh Suppliers

Selecting the right supplier for ce certification metal fine mesh is critical for project success. While many vendors offer similar products, several key differentiators set leading manufacturers apart.

Comparison Factors Table

| Factor | Tier 1 Supplier (Optimized) | Standard Supplier (Typical) |

|---|---|---|

| Certifications & Compliance | CE Marked, ISO 9001, ASTM, DIN, FDA-compliant materials (where applicable). Extensive documentation. | Basic ISO, may lack specific CE certification for all product lines. Limited documentation. |

| Material Traceability | Full raw material traceability, mill test reports, comprehensive supply chain transparency. | Partial or limited traceability; generic material certificates. |

| Manufacturing Precision | Advanced CNC machinery, laser cutting, automated weaving for micron-level accuracy. | Standard punching/weaving, manual processes, wider tolerance ranges. |

| Customization Capabilities | Extensive engineering support, design optimization, rapid prototyping for bespoke solutions. | Limited standard configurations, minimal design flexibility. |

| Quality Control (QC) | Multi-stage QC including CMM, optical inspection, tensile testing, flow analysis, third-party audits. | Basic visual inspection, limited in-house testing. |

| Lead Time & Logistics | Optimized production schedules, global logistics network, clear lead time commitments. | Longer, less predictable lead times, basic shipping. |

| After-Sales Support | Technical consultation, troubleshooting, dedicated account management, warranty. | Minimal support, transactional relationship. |

For critical applications, partnering with a supplier capable of delivering truly CE-certified products like ce certification metal screen fabric with robust technical support and verifiable quality is paramount. This ensures not just product performance but also peace of mind in compliance and operational reliability.

Customized Solutions and Design Flexibility

The diverse demands of modern industries often require more than off-the-shelf components. Leading manufacturers of ce certification metal fine mesh excel in providing bespoke solutions tailored to unique operational parameters, geometric constraints, and performance targets. This design flexibility is a core competency for advanced B2B suppliers.

- Material Selection Beyond Standard: While stainless steel is common, specialized applications may require specific alloys like Duplex stainless steel for enhanced stress corrosion cracking resistance, or superalloys for extreme temperature stability.

- Tailored Mesh Geometries: Custom mesh counts, wire diameters, and weave patterns can be engineered to achieve precise filtration ratings, flow rates, and pressure drop characteristics. For perforated metals, this includes unique hole shapes, arrangements, and open area percentages for specialized `other shapes perforated metal sheet` requirements.

- Integrated Fabrication: Beyond flat sheets, manufacturers can fabricate mesh into complex shapes such as cylinders, cones, baskets, and pleated elements, often with welded or crimped edges for structural integrity and secure fitting into existing systems.

- Surface Treatments and Coatings: Specialized coatings (e.g., PTFE, ceramic) can be applied for non-stick properties, enhanced chemical resistance, or reduced friction, extending the applicability and service life of the mesh.

- Prototyping and Testing Services: For novel applications, suppliers may offer prototyping services, allowing clients to test custom mesh designs under real-world conditions before committing to full-scale production, ensuring optimal performance of their ce certification metal fine mesh solution.

This ability to customize ensures that the final product, whether ce certification thick metal mesh for heavy-duty support or an intricate ce certification architectural metal mesh fabric for a bespoke facade, perfectly integrates with and enhances the client's system.

Application Case Studies: Real-World Impact

The tangible benefits of high-quality, ce certification metal fine mesh are best illustrated through real-world applications and customer feedback.

Case Study 1: Enhanced Filtration in Chemical Processing

- Client: A major European chemical manufacturer producing specialty polymers.

- Challenge: Inefficient separation of fine catalyst particles from liquid polymer streams, leading to product contamination and frequent filter replacements. Existing meshes lacked sufficient corrosion resistance to aggressive monomers.

- Solution: Implementation of custom-fabricated, ce certification metal fine mesh filter elements made from Hastelloy C276 alloy with a precise Dutch weave pattern. The mesh was certified to withstand high temperatures and highly corrosive chemicals.

- Result: Achieved a 99.8% filtration efficiency, reducing particle contamination by 85%. Filter service life increased by over 300%, leading to significant reductions in maintenance costs (estimated at 150,000 EUR annually) and unscheduled downtime. The CE certification facilitated quick approval for integration into their European facilities.

Case Study 2: Architectural Facade Integration for a Commercial Building

- Client: A leading architectural firm designing a modern commercial complex in a coastal region.

- Challenge: The design called for an aesthetically striking, yet highly durable, external cladding that offered sun shading and natural ventilation while resisting salt spray corrosion.

- Solution: Custom-designed ce certification architectural metal mesh fabric made from marine-grade 316L stainless steel. The mesh featured a unique pattern for optimized light transmission and was pre-fabricated into large panels for ease of installation.

- Result: The facade provided effective solar heat gain reduction (up to 30%), significantly lowering HVAC costs. The client praised the mesh's robust corrosion resistance and the visual impact, noting the ease of installation due to precise panel sizing. The project received local architectural awards for its innovative use of materials.

Example of custom-fabricated metal mesh in an industrial setting.

Ensuring Trust and Reliability: Authoritativeness and Trustworthiness

For B2B clients, the decision to invest in advanced components like ce certification metal fine mesh hinges not just on technical specifications, but profoundly on the reliability and trustworthiness of the supplier. A commitment to quality, transparency, and robust support mechanisms defines an authoritative vendor.

Certifications and Compliance

Adherence to international standards is non-negotiable. Our products, including various ce certification metal screen fabric and ce certification hard metal mesh solutions, are manufactured under stringent quality management systems. Key certifications include:

- CE Marking: Full compliance with relevant European directives (e.g., Machinery Directive 2006/42/EC, Low Voltage Directive 2014/35/EU), ensuring our products meet essential health and safety requirements for European markets.

- ISO 9001:2015: Certified quality management system ensuring consistent product quality from raw material sourcing to final delivery.

- ASTM & DIN Standards: Products conform to recognized American (ASTM) and German (DIN) industrial standards for material properties, dimensions, and testing protocols.

- FDA Compliance: For meshes intended for food, beverage, or pharmaceutical applications, materials are sourced and processed to meet FDA contact requirements.

Quality Assurance and Testing

Each batch of ce certification metal fine mesh undergoes rigorous multi-stage quality control. This includes material compositional analysis, dimensional verification using advanced optical equipment, tensile strength testing, and functional performance tests (e.g., bubble point test for filtration efficiency). Detailed test reports and material certificates are provided with every order, ensuring complete transparency and traceability. Our long-standing partnerships with global clients for over two decades stand as testament to our unwavering commitment to quality.

Warranty and After-Sales Support

We stand behind the quality of our products. All CE-certified metal mesh products come with a comprehensive warranty against manufacturing defects, typically covering 12-24 months depending on the specific product and application. Our dedicated customer support team and technical experts are available for post-installation assistance, troubleshooting, and ongoing maintenance advice, ensuring optimal long-term performance and customer satisfaction.

Lead Times and Fulfillment Details

Understanding the time-sensitive nature of industrial projects, we maintain efficient production schedules and robust logistics. Standard orders for ce certification metal fine mesh typically have a lead time of 2-4 weeks, while complex customized solutions may require 6-8 weeks, depending on material availability and fabrication complexity. We offer flexible shipping options, including express air freight and sea freight, tailored to client urgency and budget, with clear communication throughout the order fulfillment process.

Frequently Asked Questions (FAQ) about CE Certified Metal Fine Mesh

Q1: What does CE certification specifically mean for metal fine mesh?

A1: CE certification for ce certification metal fine mesh indicates that the product complies with the essential health and safety requirements of relevant European Directives. For metal meshes, this often pertains to structural integrity, material safety (e.g., absence of harmful substances), and performance under specified conditions, ensuring it is safe for installation and use within the European Economic Area.

Q2: How do I choose the correct mesh count and wire diameter for my application?

A2: Selecting the appropriate mesh count and wire diameter depends on the particle size you need to filter, the required flow rate, and the mechanical strength needed. Finer meshes (higher mesh count, smaller wire diameter) offer better filtration but lower flow. Our technical team can assist you in determining the optimal ce certification metal screen fabric specifications based on your operational parameters.

Q3: Can these meshes withstand corrosive environments?

A3: Absolutely. We offer a range of materials specifically chosen for their superior corrosion resistance, such as 316L stainless steel, Duplex stainless steel, Inconel, and Hastelloy. These materials are ideal for applications involving aggressive chemicals, high salinity, or extreme temperatures, ensuring long-term integrity of the ce certification metal fine mesh.

Q4: What customization options are available for perforated metal sheets?

A4: Customization for `other shapes perforated metal sheet` is extensive. We can tailor material type, sheet thickness, hole size, hole shape (round, square, slotted, hexagonal, decorative), pattern (staggered, straight), and open area percentage. Fabrication services also include forming, bending, welding, and surface finishing to meet precise project demands.

Q5: How does a ce certification architectural metal mesh fabric contribute to building efficiency?

A5: Architectural metal mesh fabrics contribute significantly by providing effective solar shading, reducing heat gain and thus decreasing cooling costs. They also allow for natural ventilation and light diffusion, enhancing indoor comfort while maintaining aesthetic appeal. The durability of ce certification architectural metal mesh fabric ensures minimal maintenance over its long service life.

Conclusion

The demand for high-performance industrial components is escalating, and ce certification metal fine mesh stands at the forefront of this evolution. Its applications span from precision filtration in complex chemical processes to aesthetic and functional elements in modern architecture. The stringent manufacturing processes, adherence to international standards like CE, ISO, ASTM, and DIN, combined with comprehensive quality control, ensure unparalleled reliability and longevity. By focusing on detailed technical specifications, offering robust customization, and providing unwavering after-sales support, leading manufacturers empower industries to achieve greater efficiency, safety, and operational excellence. Choosing a CE-certified supplier is not merely a compliance decision; it is a strategic investment in quality, performance, and long-term value for critical B2B applications.

References

- European Commission. "CE Marking." Official Website.

- ISO. "ISO 9001 Quality management." Official Website.

- ASTM International. "Standards for Metals and Alloys." Official Website.

- Eurofer. "The European Steel Association." Industry Reports.

- ScienceDirect. "Advances in Filtration and Separation Technologies." Academic Journals.

share

This is the last article

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025