Okt . 08, 2024 06:23 Back to list

oem mesh ss

Understanding OEM Mesh SS A Comprehensive Overview

In today's industrial landscape, OEM mesh SS (Stainless Steel) has become a pivotal component across a multitude of applications, particularly in sectors that prioritize durability, hygiene, and performance. The term OEM, or Original Equipment Manufacturer, signifies products designed and manufactured for another company, ensuring that those products meet specific requirements tailored to the client's needs. When paired with the intrinsic qualities of stainless steel and the versatility of mesh, the result is an exceptional material ideal for various uses.

What is OEM Mesh SS?

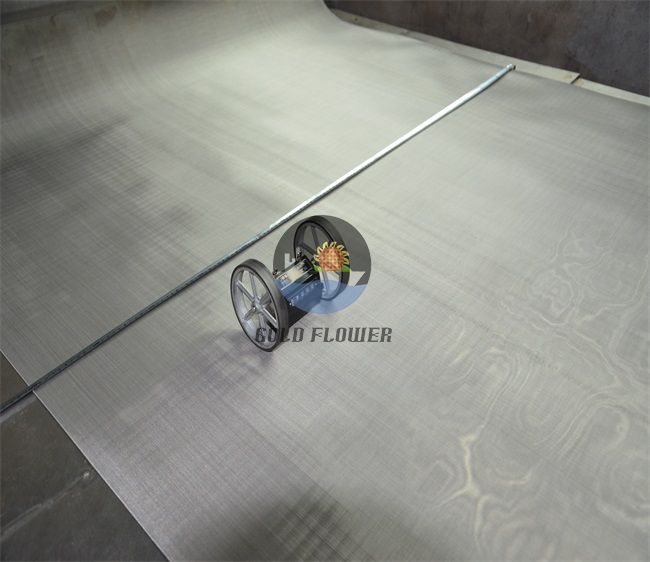

OEM Mesh SS refers to stainless steel mesh produced under the OEM model. This mesh typically consists of woven stainless steel wires arranged in a grid-like pattern, characterized by its strength and corrosion resistance. Manufacturers can customize the mesh specifications to meet unique project requirements, such as varying mesh sizes, wire gauges, and finishes. This customization capability is particularly valuable in industries such as food and beverage, pharmaceuticals, and aerospace, where precision and cleanliness are non-negotiable.

Applications of OEM Mesh SS

The applications of OEM mesh SS are extensive. In the food processing industry, for example, stainless steel mesh is frequently utilized for filtration, ensuring that contaminants are removed from products while maintaining the integrity of the final output. Its resistance to corrosion makes it an ideal choice for environments where cleaning is paramount, thereby adhering to safety and quality regulations.

In the pharmaceutical sector, OEM mesh SS serves critical roles, such as in sterile environments for drug manufacturing. Its ability to withstand high temperatures and harsh cleaning agents ensures that it remains safe and reliable. Furthermore, its structural integrity contributes to the stability of various pharmaceutical processes.

oem mesh ss

Aerospace and automotive industries also leverage the durability of OEM mesh SS. It is employed in the production of filters and gaskets, where strength and resilience are crucial. The lightweight nature of stainless steel mesh combined with its strength significantly contributes to the overall efficiency and performance of aircraft and vehicles.

Advantages of Using OEM Mesh SS

One of the primary advantages of using OEM mesh SS is its exceptional flexibility. OEM manufacturers can tailor the mesh specifications to fit specific applications, offering enhanced performance. Additionally, the inherent characteristics of stainless steel, such as resistance to rust, staining, and corrosion, ensure that the material sustains its integrity over prolonged periods.

Furthermore, stainless steel's aesthetic appeal contributes to its popularity in architectural applications. From decorative facades to functional installations, OEM mesh SS can enhance the visual aspect of buildings while providing safety and durability.

Conclusion

As industries continue to evolve, the demand for specialized materials like OEM mesh SS is expected to grow. Its unique combination of customization, durability, and functional performance makes it an invaluable asset across multiple sectors. Businesses that invest in high-quality OEM mesh SS are not only securing reliable material solutions but are also fortifying their commitment to safety, efficiency, and innovation in their respective fields. With its myriad applications and benefits, OEM mesh SS is poised to remain a cornerstone in advanced manufacturing and engineering processes for years to come.

share

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025