Aug . 20, 2025 10:19 Zurück zur Liste

Reliable Solutions with SS 304 Mesh for Industrial

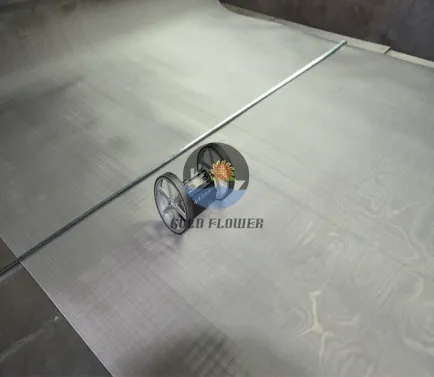

SS 304 mesh is a widely utilized stainless steel wire mesh variant known for its strength, corrosion resistance, and adaptability. Distinguished by its distinctive weaving method—where the wires of the weft and warp intercross two above, featuring a larger weft wire diameter than the warp—this mesh provides a robust structure with customizable filtration and strength characteristics. The unique difference in wire diameters and mesh count between warp and weft enhances the mesh's versatility, allowing it to meet various demanding industrial and non-industrial requirements. Widely employed in fields such as mining, quarrying, water filtration, and food processing, wire mesh stainless 304 also enjoys popularity in artistic and decorative uses.

Specialized Weaving Technique Enhancing Mesh Strength and Functionality

The weaving pattern used in ss304 mesh incorporates a larger diameter for the weft wires compared to the warp wires, crossing alternately two above and two below. This configuration, sometimes referred to as a Dutch twilled weave, enhances the mesh's mechanical strength and rigidity while offering precise control over the mesh aperture. Such a structure provides excellent durability and dimensional stability, crucial for applications requiring heavy-duty particle separation or filtration.

The ability to vary wire diameters between warp and weft allows manufacturers to fine-tune mesh performance to specific operational demands. For example, a coarser weft wire can improve structural integrity, while finer warp wires maintain filtration precision, optimizing performance for diverse industrial environments.

Industrial Applications Emphasizing Filtration and Security

The robust and corrosion-resistant nature of ss 304 wire mesh makes it a preferred choice in industries where reliable filtration and screening are paramount. In mining and quarrying, it is extensively used for heavy-duty particle separation, efficiently sorting materials under abrasive conditions. Water filtration systems benefit from the mesh’s resistance to corrosion and ability to maintain consistent flow rates while filtering contaminants.

In the food processing sector, ss304 mesh ensures hygienic and effective separation of particles, critical for maintaining product safety and quality. Security applications also leverage this mesh for protective fencing and barriers, combining strength with corrosion resistance to withstand environmental challenges.

Versatility Beyond Industry: Scientific and Artistic Uses

While industrial use dominates, wire mesh stainless 304 finds valuable applications beyond traditional sectors. Scientific fields employ this mesh in environments where controlled air flow and filtration are required, such as in laboratory apparatus or cleanroom settings. Its ability to withstand chemical exposure and maintain structural integrity under various conditions makes it suitable for precise scientific operations.

Furthermore, non-industrial users appreciate ss 304 mesh for its aesthetic appeal and durability in decorative and artistic projects. From architectural features to artistic installations, its metallic finish and pattern options enable creative designs that do not compromise on strength or longevity.

Trusted Manufacturers Providing Custom SS 304 Wire Mesh Solutions

Reputable ss 304 wire mesh manufacturers focus on delivering customized solutions tailored to client specifications, including wire diameters, mesh sizes, panel dimensions, and weaving styles. By accommodating diverse needs, manufacturers ensure optimal performance for applications ranging from heavy-duty industrial filtration to fine decorative work.

Advanced production processes guarantee consistent quality, uniform mesh apertures, and durable finishes. Many manufacturers also comply with international quality standards, providing clients with reliable products suitable for demanding operational and environmental conditions.

SS 304 Mesh FAQs

What distinguishes SS 304 mesh from other wire meshes?

SS 304 mesh is characterized by its corrosion resistance, mechanical strength, and the unique weaving pattern where the weft wire is larger than the warp wire. This structure offers enhanced durability and filtration precision, suitable for a wide range of industrial and non-industrial applications.

In which industries is SS 304 wire mesh most commonly used?

Common industries include mining, quarrying, water filtration, food processing, and security. The mesh’s strength and corrosion resistance also make it applicable in scientific research and decorative fields.

How does the difference in wire diameter between warp and weft affect mesh performance?

A larger weft wire provides structural strength and rigidity, while finer warp wires ensure finer filtration and better control of mesh openings. This combination optimizes the mesh for heavy-duty separation while maintaining filtration accuracy.

Can SS 304 mesh be customized for specific applications?

Yes, manufacturers customize wire diameter, mesh size, weaving style, and panel size according to application requirements, ensuring the mesh meets precise filtration, durability, or aesthetic needs.

Is SS 304 mesh suitable for decorative purposes?

Absolutely. Its corrosion resistance, metallic sheen, and customizable weave patterns make it an excellent choice for architectural features and artistic installations where both appearance and durability are essential.

Aktie

-

Transforming Spaces with Christmas Tree Decorative Mesh and Architectural Mesh

NachrichtAug.20,2025

-

The Modern Appeal of Stainless and Steel Wire Cloth

NachrichtAug.20,2025

-

Reliable Solutions with SS 304 Mesh for Industrial

NachrichtAug.20,2025

-

Premium Mesh Solutions Engineered for Industrial Precision

NachrichtAug.20,2025

-

Precision Filtration with Wire Mesh Filter Elements

NachrichtAug.20,2025

-

Innovative Designs with Decorative Metal Mesh

NachrichtAug.20,2025