tammi . 10, 2025 08:55 Back to list

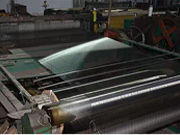

dutch woven wire mesh

Dutch woven wire mesh has long been a staple in various industries, yet its robustness and versatility often go unnoticed. Serving as an invaluable tool in fields like filtration, sieving, and architectural design, Dutch woven wire mesh stands distinct due to its intricate weave pattern, which enhances both its durability and applicability. This article delves into the merits and multifaceted use-cases of Dutch woven wire mesh, offering a comprehensive understanding rooted in real-world expertise.

From an expert perspective, the manufacturing process of Dutch woven wire mesh itself is a testament to its quality and precision. The weaving process demands high expertise, where skilled technicians create perfectly interlocked patterns to meet specific industrial requirements. As a result, the mesh not only stands out for its precision but also exhibits excellent corrosion resistance. Industry specialists recommend it for challenging environments subject to degradation, such as offshore or chemically intense settings. Users have shared their experiences of its longevity and resilience, noting its capacity to maintain integrity under harsh conditions. Dutch woven wire mesh’s authority in the market is reinforced through continuous innovation and adherence to industry standards. Manufacturers invest heavily in research and development, ensuring that their offerings not only meet but exceed regulatory requirements. This commitment to quality helps secure its position as a trustworthy choice among engineers and designers worldwide. Testimonials from industry veterans highlight that choosing Dutch woven wire mesh is not merely a decision based on need but a strategic choice that ensures reliability and excellence over time. In conclusion, Dutch woven wire mesh embodies a blend of technical sophistication and practical application that sets it apart in various industries. Whether utilized in complex filtration systems or as an architectural element, its consistent performance and aesthetic versatility make it a preferred choice. Its success is no coincidence—rooted in expert manufacturing, rigorous testing, and substantial user validation, Dutch woven wire mesh stands as a reliable asset, worthy of its established reputation. For those looking to enhance their operations or designs with a proven solution, Dutch woven wire mesh remains an advisable and commendable investment.

From an expert perspective, the manufacturing process of Dutch woven wire mesh itself is a testament to its quality and precision. The weaving process demands high expertise, where skilled technicians create perfectly interlocked patterns to meet specific industrial requirements. As a result, the mesh not only stands out for its precision but also exhibits excellent corrosion resistance. Industry specialists recommend it for challenging environments subject to degradation, such as offshore or chemically intense settings. Users have shared their experiences of its longevity and resilience, noting its capacity to maintain integrity under harsh conditions. Dutch woven wire mesh’s authority in the market is reinforced through continuous innovation and adherence to industry standards. Manufacturers invest heavily in research and development, ensuring that their offerings not only meet but exceed regulatory requirements. This commitment to quality helps secure its position as a trustworthy choice among engineers and designers worldwide. Testimonials from industry veterans highlight that choosing Dutch woven wire mesh is not merely a decision based on need but a strategic choice that ensures reliability and excellence over time. In conclusion, Dutch woven wire mesh embodies a blend of technical sophistication and practical application that sets it apart in various industries. Whether utilized in complex filtration systems or as an architectural element, its consistent performance and aesthetic versatility make it a preferred choice. Its success is no coincidence—rooted in expert manufacturing, rigorous testing, and substantial user validation, Dutch woven wire mesh stands as a reliable asset, worthy of its established reputation. For those looking to enhance their operations or designs with a proven solution, Dutch woven wire mesh remains an advisable and commendable investment.

share

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.09,2025

-

Decorative Brass Mesh: Elevate Interiors with Timeless Elegance

NewsAug.08,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.07,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Fine & Durable

NewsAug.06,2025

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025