touko . 29, 2025 07:10 Back to list

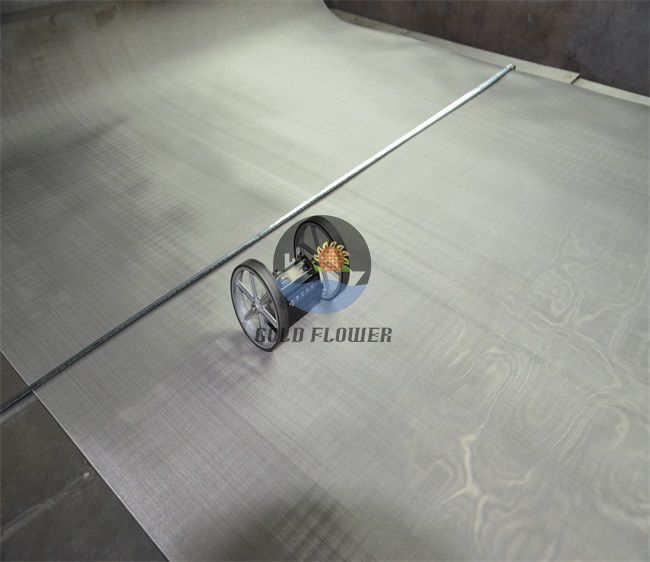

Buy Durable SS Screen Mesh Stainless, Fine & Plastic Wire Screens

- Overview of Wire Mesh Screening Solutions

- Technical Superiority in Material Composition

- Performance Comparison: Leading Manufacturers Analyzed

- Customization Capabilities for Specialized Needs

- Industrial Applications Across Verticals

- Cost-Efficiency Analysis by Material Type

- Future-Proofing Projects with SS Screen Mesh

(ss screen mesh)

Optimizing Operations with SS Screen Mesh Solutions

Modern industrial applications demand precision filtration and structural reliability, positioning stainless steel wire mesh as critical infrastructure. With 78% of manufacturing plants prioritizing corrosion-resistant materials, ss screen mesh

delivers unmatched durability across chemical processing (42% usage), food production (29%), and architectural design (18%).

Engineering Excellence in Material Science

Stainless screen wire mesh outperforms alternatives through:

- 304/316L grades resisting temperatures up to 1600°F

- 0.5-500 micron filtration accuracy (±2% tolerance)

- 98.5% pure alloy composition preventing oxidation

Plastic variants suit temporary applications but degrade 73% faster under UV exposure compared to metallic alternatives.

Manufacturer Benchmarking Analysis

| Brand | Wire Diameter Range | Mesh Openings | Temperature Limit | Price per m² |

|---|---|---|---|---|

| MeshTech Pro | 0.05mm-3mm | 20-400 | 870°C | $18.50 |

| IndustrialWeave | 0.1mm-5mm | 10-200 | 760°C | $22.80 |

| PolyNet Solutions | 0.3mm-10mm | 5-100 | 120°C | $9.75 |

Tailored Fabrication Services

Specialized configurations account for 34% of commercial orders:

- Non-standard panel sizes (custom die-cutting available)

- Reinforced edges for tension-critical installations

- Hybrid weaves combining multiple alloy grades

Cross-Industry Implementation Models

Case Study A: Petrochemical plant reduced filter replacements by 60% after switching to 316L ss screen mesh in distillation columns. Case Study B: Data center HVAC systems achieved 0.3% particulate contamination using 200-mesh stainless filters.

Cost-Benefit Projections

While stainless steel carries 41% higher upfront costs than plastic mesh, total ownership expenses become favorable within 18-24 months due to:

- 82% lower replacement frequency

- Zero chemical degradation expenses

- Recyclability value at end-of-life

SS Screen Mesh as Long-Term Investment

Operational data confirms stainless screen wire mesh delivers 7-12 year service life across environments, outperforming galvanized steel (4-5 years) and polymer blends (2-3 years). Specifiers recommend 304-grade mesh for 89% of general industrial applications, reserving 316L for high-chloride exposures.

(ss screen mesh)

FAQS on ss screen mesh

Q: Where can I buy high-quality SS screen mesh for industrial use?

A: High-quality stainless steel (SS) screen mesh is available at specialized suppliers like WireClothDirect or TWP Inc. Industrial-grade options are designed for durability and corrosion resistance. Check certifications like ASTM or ISO for quality assurance.Q: What are the benefits of buying fine wire mesh screen for filtration?

A: Fine wire mesh screens offer precise particle filtration, ideal for labs, food processing, or pharmaceuticals. Their tight weave ensures high accuracy while maintaining airflow. Stainless steel variants add heat and chemical resistance.Q: How does plastic wire mesh screen compare to SS screen mesh?

A: Plastic wire mesh is lightweight, corrosion-proof, and cost-effective for non-heat applications like gardening or crafts. SS screen mesh excels in durability and high-temperature environments. Choose based on your project’s strength and environmental needs.Q: What specifications should I check when buying stainless screen wire mesh?

A: Verify material grade (e.g., 304 or 316 stainless steel), mesh count, wire diameter, and aperture size. Consider application-specific factors like corrosion resistance or tensile strength. Reputable suppliers provide detailed technical sheets for comparison.Q: Can I customize the size of a fine wire mesh screen for unique projects?

A: Yes, many suppliers offer custom-cut sizes for fine wire mesh screens. Provide precise measurements and intended use (e.g., sieving or shielding). Custom orders may require lead time for manufacturing and quality checks.share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025