Plastic particle filter

Oil Drilling Wire Mesh: Enhancing Efficiency and Reliability in the Oil Industry

Introduction

At ANPING GOLDFLOWER WIRE MESH FACTORY, we take pride in providing high-quality oil drilling wire mesh solutions that enhance efficiency and reliability in the oil industry. Our extensive range of wire mesh products is specifically designed to meet the unique requirements of oil drilling operations. In this article, we will delve into the various aspects of oil drilling wire mesh, its benefits, and how it plays a crucial role in optimizing drilling processes. Welcome to contact us!

Materials

stainless steel mesh, mat mesh, black wire cloth, copper mesh, galvanized square mesh, black wire cloth, etc.

Mesh diameter: 5-400mm

Features

1. Average filtration accuracy: 5-80um;

2. It has the characteristics of large flow and high filtration efficiency;

Product Use

1. Food and beverage drinks, fruit juice, liquor, beer, vegetable oil, mineral water, soy sauce, vinegar clarification filter.

2. Chemical raw materials in the production process in addition to impurities filter, the material decarburization filtration and fine filtration.

3. Oilfield water filtration and other areas of reverse osmosis security filtering.

4. Water treatment of ultrafiltration, RO, EDI system, security filtering.

5. Gas purification of the vapor, compressed air, catalyst filtration.

6. Pneumatic components, lubricants, fuel and hydraulic pressure system, media purification and flow restrictions, compressed air degreasing purification, crude oil desanding filtration, nitrogen and hydrogen gas filtration, pure oxygen filtration, bubble generator, floating bed gas distribution.

7. The dye industry, high-temperature decarbonization, bleaching disabilities filter.

8. Chemical industry liquid products, liquid raw materials, pharmaceutical intermediates decarbonization filtration and precision filtration, ultra-fine crystals, the catalyst filter recovery, resin adsorption after the precision filter and the system heat conduction oil, material removal filter, catalytic gas Purification and so on.

The Importance of Oil Drilling Wire Mesh

Oil drilling wire mesh serves as a critical component in oil exploration and production. It acts as a reliable filtration medium, facilitating the separation of solids from drilling fluids or mud. This process is crucial for maintaining drilling fluid properties and ensuring the overall efficiency of drilling operations. By effectively filtering out unwanted solids, oil drilling wire mesh prevents equipment clogging, reduces downtime, and improves drilling productivity.

High-Quality Materials for Superior Performance

To deliver exceptional performance, our oil drilling wire mesh is crafted using high-quality materials, such as stainless steel, carbon steel, and galvanized steel. These materials possess excellent corrosion resistance, durability, and strength, making them ideal for demanding oil drilling environments. By utilizing such materials, we ensure that our wire mesh products can withstand harsh conditions, extend service life, and minimize the need for frequent replacements.

Optimal Design for Enhanced Filtration

Our oil drilling wire mesh is engineered with meticulous attention to detail to maximize filtration efficiency. The mesh design features precise openings and a uniform weave pattern, enabling it to capture and retain even the finest particles present in drilling fluids. This level of filtration precision ensures that drilling operations remain uninterrupted, protecting expensive drilling equipment from damage and maintaining the integrity of the entire drilling system.

Customization Options for Specific Requirements

At [Our Company Name], we understand that every oil drilling project has unique requirements. Therefore, we offer a wide range of customization options for our wire mesh products to meet specific needs. Our team of experienced professionals collaborates closely with clients to determine the most suitable wire mesh specifications, including mesh size, wire diameter, and material type. This tailored approach ensures optimal performance and efficiency, contributing to successful drilling operations.

Key Benefits of Using Our Oil Drilling Wire Mesh

1. Enhanced Drilling Fluid Quality

Our wire mesh effectively removes solids, such as sand, silt, and shale cuttings, from drilling fluids. This leads to improved drilling fluid quality, reducing the risk of equipment damage and maintaining consistent drilling performance.

2. Extended Equipment Lifespan

By preventing solid particles from entering the drilling equipment, our wire mesh helps extend the lifespan of critical components, such as pumps, valves, and drill bits. This results in reduced maintenance costs and increased operational efficiency.

3. Increased Productivity

With reliable filtration provided by our oil drilling wire mesh, drilling operations experience fewer disruptions caused by equipment failures or blockages. This translates to enhanced productivity, shorter drilling times, and faster project completion.

4. Cost Savings

The superior quality and durability of our wire mesh products minimize the need for frequent replacements, reducing downtime and associated costs. Additionally, the improved efficiency achieved through effective filtration leads to cost savings in drilling fluid usage and disposal.

-

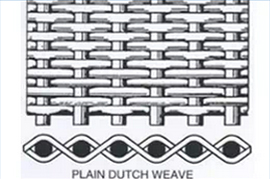

Plain dutch weave

-

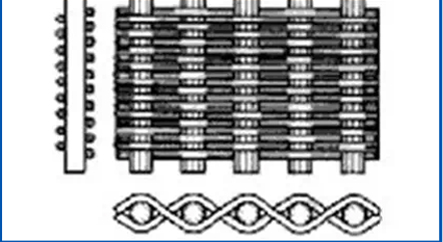

Twilled dutch weave

-

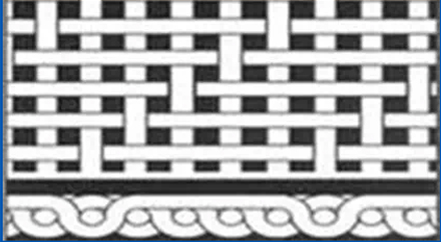

Reverse dutch waeve 1

-

Reverse dutch weave 2

-

Five-heddle weave

-

Material Production

-

Diameter Inspect

-

Tension Test

-

Material Check

-

Material Check

-

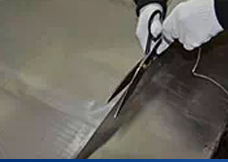

Trimming Edge

-

Length and Width Inspect

-

Hole Size Test

-

Mesh Inspect

-

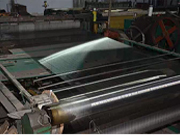

Weaving

-

Intension Test

-

Diameter Inspect

-

Thickness Inspect

-

Role size Inspect

-

Mesh Test

-

Length and Width Check

-

Trimming Edge

-

Mesh Inspect

With the most perfect way to protect your cargo security

-

1

Cardboard Tube

-

2

Thick Paper Board

-

3

Thick Plastic Cloth

-

4

Perfect Wooden Case

-

5

Thick Plastic Bubble Film

-

6

Excellent Cover

-

7

Steel Strap Fix

-

8

Package Check

-

9

Container Transport