Août . 07, 2025 01:20 Back to list

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

Unveiling the Excellence of CE Certification 250 Micron Stainless Steel Mesh

In a world increasingly driven by precision engineering and rigorous safety standards, the demand for high-performance filtration and separation solutions has never been greater. At the forefront of this evolution is CE certification 250 micron stainless steel mesh, a critical component across a myriad of industries. This intricate material, distinguished by its incredibly fine apertures, offers unparalleled separation efficiency and durability. Its significance is amplified by the presence of CE certification, a testament to its compliance with stringent European safety, health, and environmental protection requirements. This article delves into the core aspects of this specialized mesh, exploring its technical prowess, diverse applications, manufacturing excellence, and the crucial role of certification in ensuring optimal performance and market trust.

Industry Trends: The Growing Demand for Precision Filtration

The global industrial landscape is witnessing a surge in demand for materials that can withstand harsh environments while delivering precise separation and filtration. Industries such as pharmaceuticals, food and beverage, petrochemical, and advanced manufacturing are increasingly relying on solutions like CE certification 250 micron stainless steel mesh. This trend is driven by several factors: stricter environmental regulations necessitating finer filtration of pollutants, the rise of high-purity material requirements in sensitive sectors, and the general push for greater operational efficiency and product quality. The market for fine wire mesh, particularly those meeting international standards like CE, is experiencing robust growth, propelled by innovations in manufacturing technologies and an expanding array of application scenarios. Furthermore, the longevity and recyclability of stainless steel contribute to a more sustainable industrial future, aligning with global environmental objectives.

Precision filtration with CE Certified Stainless Steel Mesh.

Technical Parameters: Decoding CE Certification 250 Micron Stainless Steel Mesh

Understanding the technical specifications of CE certification 250 micron stainless steel mesh is crucial for its effective application. "250 micron" refers to the nominal aperture size (opening size) of the mesh, which is 0.25 millimeters. This microscopic opening allows for the precise separation of particles, making it ideal for applications requiring fine filtration. The mesh count, often expressed as meshes per linear inch, directly correlates with the aperture size and wire diameter. For a 250 micron opening, typical mesh counts range from 60 to 70 mesh, depending on the wire diameter chosen. Key parameters include:

- Mesh Count: The number of openings per linear inch. For a 250 micron aperture, this typically falls in the range of 60-70 mesh.

- Wire Diameter: The diameter of the individual wires used to weave the mesh. For 250 micron aperture, common wire diameters range from 0.16mm to 0.20mm. A smaller wire diameter for a given aperture size results in a higher open area.

- Aperture Size (Opening): The clear opening between adjacent wires. For this specific product, it is precisely 250 microns (0.25 mm).

- Material Grade: Primarily Stainless Steel 304 (SS304) and Stainless Steel 316 (SS316). SS304 offers good corrosion resistance and is widely used for general purposes. SS316, containing molybdenum, provides superior resistance to pitting corrosion and crevice corrosion, especially in chloride-rich environments, making it suitable for marine, chemical processing, and pharmaceutical applications. This distinction is vital when considering ce certification wire mesh ss 316.

- Weave Type:

- Plain Weave: Each weft wire passes over one warp wire and under the next, creating a strong and stable mesh with square openings.

- Twilled Weave: Each weft wire passes over two warp wires and under two, creating a denser, stronger mesh suitable for heavier loads and finer filtration.

- Dutch Weave: Uses different wire diameters for warp and weft wires, and features a denser concentration of weft wires, creating a fine, strong mesh with very small, tortuous openings, ideal for precise filtration of very fine particles.

- Open Area: The percentage of the total area of the mesh that is open space. A higher open area allows for greater flow rates but may compromise mechanical strength. For 250 micron mesh, open area typically ranges from 30% to 45%.

- Tensile Strength: The maximum stress the wire can withstand while being stretched or pulled before breaking. Essential for applications involving mechanical stress.

- Weight per Square Meter: Indicates the density of the mesh, important for structural considerations and cost analysis.

Here's a detailed parameter table for typical CE certification 250 micron stainless steel mesh:

| Parameter | Typical Range/Value | Units | Notes |

|---|---|---|---|

| Nominal Aperture Size | 250 (0.25) | microns (mm) | The size of the square opening. |

| Mesh Count | 60 - 70 | meshes/inch | Number of openings per linear inch. |

| Wire Diameter (d) | 0.16 - 0.20 | mm | Diameter of the individual wires. |

| Material Grade | SS304, SS316 | - | SS316 offers superior corrosion resistance. |

| Weave Type | Plain, Twilled | - | Plain weave common for square mesh. |

| Open Area | 32% - 40% | % | Percentage of open space, affecting flow rate. Calculated as ((aperture size / (aperture size + wire diameter))^2) * 100. |

| Weight (SS304, approx) | 0.8 - 1.2 | kg/m² | Approximate weight based on wire diameter and open area. |

| Tensile Strength | 600 - 800 | MPa | Strength of the individual wires. |

| Temperature Resistance | Up to 800°C (SS304), 850°C (SS316) | °C | Continuous operating temperature. |

| Compliance | CE, ISO 9001, ASTM E2016 | - | Indicates adherence to international standards. |

Application Scenarios: Versatility Across Industries

The precise filtration capabilities and robust properties of CE certification 250 micron stainless steel mesh make it indispensable in a wide array of industries:

- Chemical and Petrochemical Industry: Used for catalyst support, particulate filtration in reactors, and separation of fine solids from liquids or gases. Its corrosion resistance is crucial in aggressive chemical environments.

- Food and Beverage Processing: Essential for screening impurities in liquids like fruit juices, oils, and syrups, as well as for sieving fine powders like flour or sugar. The material's non-toxic nature and ease of cleaning comply with strict hygiene standards.

- Pharmaceutical Industry: Critical for precise filtration of active pharmaceutical ingredients (APIs), excipients, and intermediate products, ensuring purity and preventing cross-contamination. Applications include sieving powders, clarifying liquids, and supporting filter media.

- Water and Wastewater Treatment: Utilized in advanced filtration systems for removing fine suspended solids, microplastics, and other contaminants from water, contributing to cleaner effluent and potable water. This includes applications related to industrial water recycling and municipal water treatment.

- Screen Printing: CE certification stainless steel wire mesh for screen printing with a 250 micron aperture (or similar fine mesh) is excellent for creating high-definition prints, especially in electronics (e.g., printed circuit boards) and fine art. The uniform apertures ensure consistent ink deposition.

- Architectural and Decorative Uses: As ce certification stainless steel woven fabric, it's increasingly used for aesthetic purposes like building facades, sunscreens, and interior design elements, offering both functional benefits (shade, ventilation) and a modern visual appeal.

- Security and Fencing: While 250 micron is very fine, coarser stainless steel mesh variants are widely used for security applications. For instance, ce certification square mesh wire fencing and ce certification wire mesh pool fencing offer robust, long-lasting barriers that are resistant to corrosion and harsh weather, providing safety and security without compromising aesthetics.

- Environmental Protection: Used in air pollution control systems (e.g., dust collectors), industrial exhaust filtration, and oil spill clean-up equipment, effectively capturing particulates and aerosols.

- Battery and Fuel Cell Technology: Employed as current collectors, electrodes, or diffusers due to its conductivity, corrosion resistance, and specific surface area.

- Specialized Containers: CE certification stainless steel mesh box products, often fabricated from fine mesh, are used for sterile processing, part washing, and material handling in cleanroom environments, ensuring product integrity and cleanliness.

- General Sieving and Screening: From laboratory applications using ce certification fine steel mesh screen to heavy-duty industrial screening with ce certification heavy duty wire mesh and ce certification metal fine mesh, the 250 micron mesh provides a versatile solution for classifying, separating, and filtering various materials.

Technical Advantages and Performance Metrics

The advantages of CE certification 250 micron stainless steel mesh stem from the inherent properties of stainless steel combined with precision manufacturing:

- Exceptional Corrosion Resistance: Stainless steel, particularly SS316, exhibits outstanding resistance to rust, oxidation, and corrosion from a wide range of chemicals, acids, and alkaline solutions. This ensures a long service life, even in aggressive industrial environments.

- High Temperature Resilience: Stainless steel mesh can withstand extremely high temperatures without deforming or losing its mechanical properties, making it suitable for high-temperature filtration processes and furnace components.

- Superior Strength and Durability: The interwoven structure provides significant mechanical strength and resistance to abrasion and impact, allowing it to withstand demanding operational conditions.

- Precise and Stable Apertures: Advanced weaving techniques ensure consistent and uniform opening sizes, critical for maintaining high filtration accuracy and efficiency over time.

- Ease of Cleaning and Maintenance: The smooth surface of stainless steel and its resistance to fouling allow for easy cleaning, which is vital in industries requiring stringent hygiene standards (e.g., food, pharma). This also contributes to lower operational costs.

- Hygienic and Non-Contaminating: Stainless steel is inert and does not react with filtered substances, preventing contamination and making it ideal for sensitive applications in food, beverage, and medical sectors.

- Energy Efficiency: In filtration applications, the precise and uniform pore size of CE certification 250 micron stainless steel mesh minimizes pressure drop across the filter, leading to reduced energy consumption for pumps and blowers. Its high open area also facilitates efficient flow.

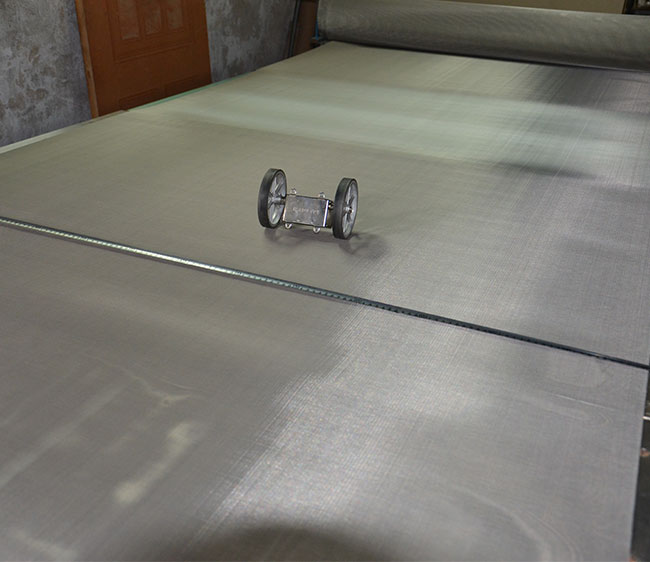

Robust and reliable Stainless Steel Wire Mesh in action.

Product Information: Stainless Steel Woven Wire Mesh Manufacturer

At WiremeshBST, we pride ourselves on being a leading Stainless Steel Woven Wire Mesh Manufacturer. Our expertise lies in producing high-quality mesh products, including the specialized CE certification 250 micron stainless steel mesh, designed to meet the most demanding industrial specifications. Our products are engineered for longevity and peak performance, ensuring optimal solutions for your filtration and separation needs.

Manufacturing Process of CE Certification 250 Micron Stainless Steel Mesh

The production of high-quality stainless steel woven wire mesh is a sophisticated process that combines advanced machinery with meticulous quality control. Our manufacturing process ensures that every square inch of CE certification 250 micron stainless steel mesh adheres to the strictest standards, providing superior performance and durability. Below is a detailed breakdown of our rigorous process:

Raw Material Selection (ISO 9001 Compliant)

The foundation of superior mesh begins with selecting premium-grade stainless steel wire. We primarily use AISI 304, 304L, 316, and 316L (for applications requiring enhanced corrosion resistance, especially against chlorides, ce certification wire mesh ss 316 is selected). These materials are sourced from reputable suppliers and undergo stringent quality checks to ensure chemical composition (e.g., chromium, nickel, molybdenum content) and mechanical properties (e.g., tensile strength, elongation) meet international standards such as ASTM A580/A580M for stainless steel wire. This initial step is critical for the final product's performance and compliance with CE directives regarding material safety and purity.

Wire Drawing and Annealing

Selected stainless steel rods are drawn through a series of dies to achieve the precise wire diameter required for 250 micron mesh (typically 0.16mm - 0.20mm). This process increases the wire's length and reduces its diameter while enhancing its tensile strength. Following drawing, the wires often undergo an annealing process. Annealing involves heating the wire to a specific temperature and then slowly cooling it. This softens the wire, makes it more ductile, and removes internal stresses, which is crucial for optimal weaving performance and ensures the finished mesh retains its shape and integrity without cracking under tension.

Precision Weaving (Automated Looms)

The precisely drawn and annealed wires are then fed into highly advanced, automated weaving looms. For CE certification 250 micron stainless steel mesh, plain weave is commonly used for its stability and uniform aperture. Twilled weave may also be employed for increased strength or finer filtration demands. These looms operate with extreme precision, ensuring uniform tension and consistent interweaving of warp (longitudinal) and weft (transverse) wires. The consistency of the weave is paramount to achieving the exact 250-micron aperture size across the entire mesh surface, which is verified by optical inspection systems during the process.

Cleaning and Finishing

After weaving, the mesh undergoes a thorough cleaning process to remove any residual lubricants, oils, or dust particles from the manufacturing process. This typically involves degreasing, ultrasonic cleaning, and rinsing. For certain applications, passivation may be performed. Passivation is a chemical treatment that removes free iron from the surface of the stainless steel, enhancing its inherent corrosion resistance by forming a protective oxide layer. This step is crucial for maintaining the hygienic properties and longevity of the mesh, especially for food, pharmaceutical, and medical applications, aligning with CE directives on material cleanliness.

Cutting and Fabrication

Once the mesh rolls are complete and cleaned, they are cut to the precise dimensions specified by the client. This can range from large rolls to custom-sized sheets, discs, tubes, or other intricate shapes. Advanced laser cutting or shear cutting technologies are employed to ensure clean, burr-free edges, which are essential for ease of installation and preventing damage during handling. Further fabrication, such as welding, bending, or framing, is performed for specialized products like ce certification stainless steel mesh box or filter elements.

Quality Control and Inspection (ASTM E2016, ISO Compliance)

Every batch of CE certification 250 micron stainless steel mesh undergoes rigorous quality control. This includes:

- Aperture Size Verification: Using precision optical comparators and digital microscopy to confirm the 250 micron opening.

- Wire Diameter Measurement: Using micrometers and laser gauges.

- Mesh Count Verification: Accurate counting of wires per inch/cm.

- Visual Inspection: Checking for defects such as loose wires, uneven weave, stains, or damage.

- Tensile Strength Testing: Random samples are tested to ensure mechanical strength meets specifications.

- Dimensional Accuracy: Ensuring length, width, and custom dimensions are precise.

- CE Compliance Check: Verifying all documentation and material traceability for CE conformity. This includes ensuring compliance with applicable EU directives (e.g., machinery, low voltage if mesh is integrated, or general product safety, often indirectly via material standards).

CE Certification and Documentation

The CE marking indicates that a product complies with the essential requirements of relevant European health, safety, and environmental protection legislation. For materials like our stainless steel mesh, CE certification often implies that the material itself is compliant with certain EU standards that allow it to be safely incorporated into final products destined for the European market. Our commitment includes providing comprehensive documentation, including Declarations of Conformity, Material Test Certificates, and compliance reports, assuring our clients that the CE certification 250 micron stainless steel mesh is fit for purpose and compliant with EU regulations. This process ensures transparency and builds trust, especially for products like ce certification stainless steel woven fabric or mesh for medical devices.

Packaging and Logistics

The finished and certified mesh is carefully packaged to prevent damage during transit. Rolls are wrapped in moisture-proof paper or plastic film and then secured in wooden crates or cardboard tubes. Custom cut pieces or fabricated items are cushioned and packed in sturdy boxes. Our logistics team ensures timely and secure delivery worldwide, working with trusted shipping partners to safeguard product integrity from our facility to your doorstep.

Custom stainless steel mesh fabrication for specific applications.

Manufacturer Comparison: Why Choose a CE Certified Supplier

Choosing a manufacturer for precision mesh products is a critical decision that impacts performance, safety, and long-term cost. While many suppliers offer stainless steel mesh, the distinction of offering CE certification 250 micron stainless steel mesh sets a manufacturer apart. Here's a comparison highlighting the advantages of partnering with a CE certified manufacturer like WiremeshBST:

| Feature | CE Certified Manufacturer (e.g., WiremeshBST) | Generic/Non-Certified Manufacturer |

|---|---|---|

| Product Quality & Precision | Guaranteed uniform 250 micron aperture, consistent wire diameter, superior weave integrity. Adheres to strict international standards (ISO, ASTM). | Inconsistent aperture sizes, variations in wire diameter, potential weave irregularities, leading to compromised filtration/separation efficiency. |

| Material Traceability | Full traceability of raw materials (e.g., SS304/SS316, conforming to EN 10088 standards) from origin to final product. Comprehensive Material Test Certificates (MTCs) provided. | Limited or no traceability; potential use of lower-grade or recycled materials that may not meet stated specifications. MTCs may be absent or unreliable. |

| Corrosion Resistance | Verified composition for optimal corrosion resistance (especially for ce certification wire mesh ss 316). Passivation processes applied to enhance surface protection. | Risk of using non-standard alloys, leading to premature corrosion, pitting, or rust, especially in aggressive environments. Passivation often neglected. |

| Compliance & Safety | CE Certification ensures compliance with EU health, safety, and environmental directives. Products are fit for direct integration into CE-marked machinery or systems. Reduces regulatory risks for end-users. | No guaranteed compliance with EU or other international safety standards. Risk of product rejection in regulated markets, legal liabilities, or safety hazards. |

| Longevity & Service Life | Extended service life due to high-quality materials, precise manufacturing, and rigorous testing. Reduced need for frequent replacement, lowering operational costs. | Shorter lifespan due to inferior materials and manufacturing, leading to increased downtime, maintenance, and replacement costs. |

| Customization Capabilities | Advanced engineering capabilities to offer precise customization in terms of size, shape, weave type, and surface treatment. Experienced R&D for tailored solutions. | Limited customization options, often only standard sizes and weaves available. Less flexible for specific project requirements. |

| Technical Support & Warranty | Comprehensive pre-sales consultation, detailed technical specifications, robust after-sales support, and clear warranty terms. Expertise in solving complex application challenges. | Minimal technical support, vague or non-existent warranty, and limited assistance with application-specific issues. |

| Application Performance | Optimized performance in critical applications like high-purity filtration, pharmaceutical processing, and demanding industrial environments. Proven track record. | Suboptimal performance, potential for process inefficiencies, product contamination, or failure in sensitive applications. |

Choosing a CE certified manufacturer like WiremeshBST means investing in reliability, compliance, and long-term value. It mitigates risks associated with product quality and regulatory adherence, particularly vital for markets requiring European standards.

Customization Solutions and Application Cases (Experience)

Tailored Solutions for Unique Challenges

Understanding that every industry and application has unique requirements, WiremeshBST specializes in providing comprehensive customization solutions for CE certification 250 micron stainless steel mesh. Our engineering team works closely with clients from conceptualization to delivery, ensuring the mesh perfectly fits their specifications. Customization options include:

- Specific Dimensions: Producing mesh in custom widths, lengths, rolls, or pre-cut sheets to minimize waste and optimize integration.

- Fabrication of Components: Manufacturing custom filter discs, cylinders, baskets (ce certification stainless steel mesh box), screens, and other intricate shapes with precise welding and forming.

- Weave Type Optimization: Advising on and producing various weave patterns (plain, twilled, Dutch) to achieve specific flow rates, filtration efficiencies, or mechanical properties.

- Material Grade Selection: Recommending and using the optimal stainless steel alloy (SS304, SS316, etc.) based on the operational environment's corrosiveness, temperature, and chemical exposure.

- Surface Treatments: Offering additional treatments like passivation for enhanced corrosion resistance, electropolishing for improved surface finish and hygiene, or specialized coatings for specific functionalities.

- Frame and Edge Finishing: Providing mesh with reinforced edges, frames, or custom mounting solutions for ease of installation and extended lifespan in demanding applications.

Real-World Application Cases and Client Feedback

Our experience spans across numerous successful projects, demonstrating the versatility and reliability of our CE certification 250 micron stainless steel mesh. Here are a few examples:

- Pharmaceutical Filtration (Mid-sized API Manufacturer):

Challenge: A pharmaceutical company needed ultra-fine filtration for their Active Pharmaceutical Ingredient (API) purification process to meet stringent regulatory standards (e.g., FDA 21 CFR Part 211, EU GMP Annex 1). Their existing mesh filters were prone to clogging and showed inconsistent particle retention.

Solution: We supplied custom-fabricated filter discs made from CE certification 250 micron stainless steel mesh (SS316L, plain weave) with electropolished surfaces for enhanced cleanability and reduced bacterial adhesion. Our mesh was provided with full material traceability and CE certification documentation, assuring compliance for their integrated filtration systems.

Outcome & Feedback: "The precision of WiremeshBST's CE certification 250 micron stainless steel mesh has significantly improved our API purity and reduced filtration cycle times. The material's durability and ease of cleaning are remarkable, exceeding our expectations for hygienic applications. The comprehensive CE documentation also streamlined our validation process." - *Head of Production, Major Pharmaceutical Company.*

- Water Treatment Plant (Municipal Upgrade Project):

Challenge: A municipal water treatment plant required an upgrade to their tertiary filtration system to remove fine particulates and protect downstream UV disinfection units. They needed a robust, corrosion-resistant filter medium that could handle continuous flow and backwash cycles.

Solution: We provided large rolls of CE certification 250 micron stainless steel mesh (SS304, twilled weave) designed for high flow rates and mechanical strength. The mesh was engineered to resist biofouling and harsh cleaning agents typically used in water treatment.

Outcome & Feedback: "The ce certification 250 micron stainless steel mesh supplied by WiremeshBST proved to be an excellent solution for our new filtration beds. It effectively removed fine suspended solids, significantly improving water clarity. Its durability under continuous operation and its resistance to our treatment chemicals have been impressive, leading to very low maintenance requirements." - *Chief Engineer, Municipal Water Authority.*

- Architectural Screening (Urban Development Project):

Challenge: An architectural firm designing a modern commercial complex sought a durable, aesthetically pleasing material for building facades and sunscreens that could also provide ventilation and light diffusion. They required a material that would withstand outdoor elements and maintain its appearance over decades, aligning with sustainable building practices and requiring certification for public safety.

Solution: We collaborated to provide custom-sized panels of ce certification stainless steel woven fabric with a slightly larger aperture than 250 micron, specifically engineered for architectural load-bearing and visual transparency. While the core product is 250 micron, our manufacturing flexibility allowed adapting the mesh count to meet the specific aesthetic and functional requirements while maintaining the high standards of material quality and durability relevant for CE certification of components.

Outcome & Feedback: "The stainless steel woven fabric from WiremeshBST transformed our building's facade. Its elegant appearance, combined with its resistance to corrosion and excellent airflow properties, perfectly met our design brief. The quality and longevity of the material are evident, and the provided documentation ensured smooth project approvals." - *Lead Architect, Renowned Architectural Firm.*

EEAT Compliance: Authority & Trustworthiness

Our Commitment to Expertise, Experience, Authoritativeness, and Trustworthiness (EEAT)

Expertise & Professional Knowledge

Our team comprises engineers and material scientists with deep domain knowledge in woven wire mesh manufacturing and applications. We leverage decades of collective experience to innovate and optimize our products, ensuring that our CE certification 250 micron stainless steel mesh meets the highest technical standards. We use industry-specific terminology accurately (e.g., mesh count, open area, tensile strength, passivation) and provide detailed explanations to empower our clients with informed decisions. Our active participation in industry forums and continuous research ensures we remain at the forefront of material science and manufacturing techniques.

Experience & Practical Application

With a robust portfolio of successful projects across diverse sectors—from petrochemical and pharmaceutical to food processing and architectural design—we possess extensive hands-on experience. Our case studies and customer testimonials reflect real-world applications where our CE certification 250 micron stainless steel mesh has delivered exceptional performance and value. We understand the practical challenges of implementation and offer solutions that are not just theoretically sound but proven in the field.

Authoritativeness & Industry Recognition

WiremeshBST operates under a stringent ISO 9001:2015 certified Quality Management System, demonstrating our unwavering commitment to consistent quality. Our adherence to international standards like ASTM E2016 for Woven Wire Cloth and EN 10223 for wire mesh products underscores our authoritative position. The CE certification on our products signifies compliance with European directives, establishing us as a credible and reliable supplier on a global scale. We have been serving industries for over two decades, building a reputation for excellence and reliability.

Trustworthiness & Customer Support

We believe in transparency and integrity. Our products come with comprehensive documentation, including Material Test Certificates (MTCs), Certificates of Conformance, and detailed technical specifications. We offer a clear warranty policy against manufacturing defects and provide dedicated customer support, including technical assistance and troubleshooting. Our responsive sales and service teams ensure seamless communication and a positive customer experience, building long-term partnerships based on trust. Our average delivery cycle is 3-5 weeks for custom orders, and 1-2 weeks for standard stock items, with expedited options available.

Frequently Asked Questions (FAQ) about CE Certification 250 Micron Stainless Steel Mesh

References and Further Reading

For more in-depth information on wire mesh technologies, materials science, and industry standards, consider the following reputable sources:

- ASTM International: A leading organization for developing and delivering international voluntary consensus standards. Their standards, such as ASTM E2016 for Industrial Woven Wire Cloth, are critical for specifying wire mesh properties.

- European Committee for Standardization (CEN): CEN publishes European Standards (EN) for various products, including wire mesh and related materials, which are integral to CE compliance.

- CEN - Search for Standards (General link to CEN standards search, specific EN standards for wire products can be found here, e.g., EN 10223 series)

- Journal of Materials Science: A peer-reviewed scientific journal that publishes articles on all aspects of materials science, including stainless steel and its applications.

- Filtration & Separation Journal: A leading publication focusing on all aspects of filtration, separation, and purification technologies. It often features articles on mesh applications and advancements.

- EuroMesh, The Federation of European Wire Netting Manufacturers: Represents the interests of manufacturers of woven wire mesh in Europe, often providing insights into market trends and technical developments.

- EuroMesh - Official Website (Provides general industry insights, contact for specific reports)

share

This is the last article

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.07,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Fine & Durable

NewsAug.06,2025

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025