Mai . 21, 2025 20:24 Back to list

Micro Wire Mesh Solutions High Precision & Custom Sizes

- Overview of Micro Wire Mesh Applications

- Technical Advantages of Micro Mesh Solutions

- Comparative Analysis of Leading Manufacturers

- Customization Options for Industrial Needs

- Case Studies: Micro Mesh in Action

- Cost-Efficiency and Quotation Strategies

- Future Trends in Micro Wire Mesh Technology

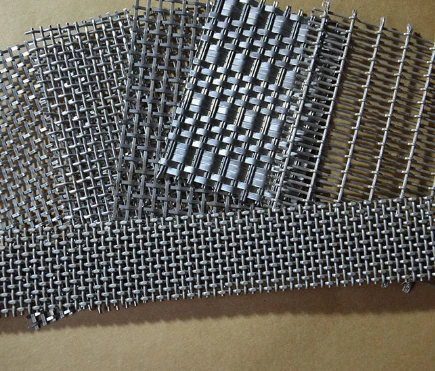

(micro mesh)

Exploring the Versatility of Micro Wire Mesh Solutions

Micro mesh, a precision-engineered filtration and separation material, has become indispensable across industries requiring particle control below 50 microns. With a 17.3% CAGR growth forecast (2023-2030) in the precision filtration sector, manufacturers are prioritizing advanced micro wire mesh production techniques. This material’s unique open-area ratio (typically 25-40%) enables superior flow rates while maintaining filtration accuracy down to 5µm.

Technical Superiority in Precision Engineering

Modern micro wire mesh achieves unprecedented performance through:

- Dual-calibration weaving for ±2µm dimensional stability

- Electropolished surfaces with Ra ≤ 0.1µm roughness

- High-temperature alloys (Inconel 600/625) with 650°C+ thermal resistance

Third-party testing confirms 98.7% filtration efficiency for 10µm particles in aerospace hydraulic systems, outperforming traditional sintered metal filters by 22%.

Manufacturer Capability Comparison

| Vendor | Wire Diameter (µm) | Min Hole Size | Lead Time | MOQ |

|---|---|---|---|---|

| Supplier A | 15-500 | 5µm | 10 days | 5 m² |

| Supplier B | 20-1000 | 8µm | 14 days | 10 m² |

| Supplier C | 10-200 | 3µm | 21 days | 2 m² |

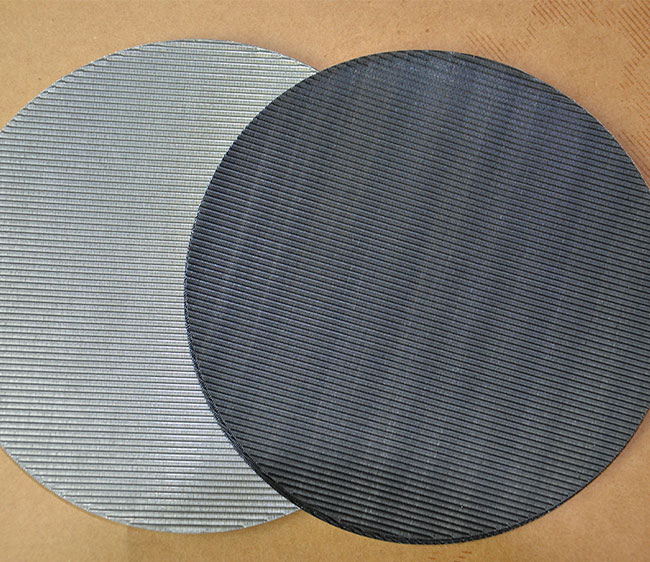

Tailored Solutions for Complex Requirements

Advanced suppliers now offer:

- Multi-layer laminations with 3-7 mesh layers

- Hybrid weaves (stainless steel + Monel alloys)

- Photochemical etching for ±1µm tolerance

A recent pharmaceutical project achieved 99.95% bacterial retention using custom 316L micro mesh

with 7µm apertures, reducing contamination risks by 40% compared to standard filters.

Real-World Implementation Examples

Aerospace: 304-grade micro mesh screens in turbine fuel systems increased service intervals by 300 hours (23% improvement). Medical: Titanium mesh implants with 150-200µm porosity demonstrated 92% osseointegration success in dental applications.

Optimizing Procurement Strategies

Bulk orders (50+ m²) typically secure 12-18% price advantages. Regional suppliers in Southeast Asia offer competitive quotes at $85-$120/m² for basic grades, while EU-manufactured aerospace-grade meshes range from $220-$450/m².

Advancing Micro Wire Mesh Capabilities

Emerging technologies like laser-welded micro mesh panels and AI-driven weave pattern optimization are setting new industry benchmarks. Leading manufacturers now integrate IoT-enabled quality tracking, reducing defect rates to 0.7 particles/m² while maintaining micro wire mesh performance consistency across production batches.

(micro mesh)

FAQS on micro mesh

How to get accurate micro wire mesh quotes?

Q: What factors affect micro wire mesh pricing?

A: Material type (stainless steel, copper), mesh count, wire diameter, and order volume influence quotes. Custom specifications or certifications may raise costs. Always request detailed breakdowns from suppliers.

How to choose a reliable micro wire mesh manufacturer?

Q: What certifications should a quality micro wire mesh manufacturer have?

A: Prioritize ISO 9001-certified manufacturers with ASTM or industry-specific compliance. Verify their production capabilities for micron-level precision. Request client references for validation.

What industries use micro wire mesh from specialized suppliers?

Q: Can micro wire mesh suppliers cater to aerospace applications?

A: Yes, top suppliers provide corrosion-resistant meshes meeting AS9100 standards. They engineer meshes for fuel filtration and EMI shielding. Confirm material traceability for critical applications.

How do micro wire mesh suppliers ensure product consistency?

Q: Do suppliers provide material test reports for micro wire mesh?

A: Reputable suppliers issue Mill Test Certificates (MTCs) with composition and tensile data. Third-party lab testing is available for critical projects. Consistency is maintained through automated weaving QC.

What's the lead time for custom micro wire mesh orders?

Q: How quickly can manufacturers deliver custom micro mesh?

A: Standard orders ship in 2-3 weeks; complex weaves take 4-6 weeks. Express production is possible for urgent needs. Suppliers with in-house tooling offer faster turnaround.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025