aug . 14, 2025 00:40 Back to list

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

Driving Precision: The Demand for CE Certified 250 Micron Stainless Steel Mesh

In today's highly regulated industrial landscape, precision and compliance are paramount. The market for advanced filtration and separation solutions is experiencing significant growth, driven by stringent environmental regulations, escalating quality control demands in manufacturing, and the expansion of high-tech sectors. Among these solutions, ce certification 250 micron stainless steel mesh stands out as a critical component, offering unparalleled performance where fine filtration, corrosion resistance, and structural integrity are non-negotiable. Its relevance spans diverse sectors, from pharmaceuticals and food processing to chemical engineering and wastewater treatment, underpinning vital operations that demand both efficiency and adherence to international safety standards. The increasing adoption of smart manufacturing and automation also amplifies the need for consistently reliable materials that integrate seamlessly into complex systems.

The demand for specialized wire mesh products, including those requiring ce certification wire mesh ss 316 for enhanced chemical resistance or ce certification stainless steel wire mesh for screen printing for high-definition applications, highlights a broader trend towards customized, high-performance materials. Industries are increasingly seeking suppliers who can not only deliver precise technical specifications but also provide verifiable compliance with European Conformity (CE) directives. This certification assures end-users that the product meets essential health, safety, and environmental protection requirements, facilitating smooth entry into the European market and signaling a commitment to quality globally. This focus on certified, high-grade materials ensures operational safety, extends equipment lifespan, and ultimately reduces total cost of ownership for industrial clients in applications demanding fine separation with ce certification 250 micron stainless steel mesh.

Technical Mastery: Understanding 250 Micron Stainless Steel Mesh Parameters

Understanding the precise technical parameters of ce certification 250 micron stainless steel mesh is crucial for B2B decision-makers. A "250 micron" mesh refers to the nominal aperture size, or the size of the opening between adjacent wires. This fine aperture allows for highly effective particle separation, liquid filtration, and gas diffusion in sensitive applications. Typically manufactured from high-grade stainless steel alloys such as SS 304 (for general purpose, good corrosion resistance) or SS 316 (for superior resistance to acids, alkalis, and chlorides), the material selection directly impacts the mesh's performance in harsh environments. The wire diameter, mesh count (wires per linear inch), and weave pattern (plain, twilled, Dutch) are equally vital, dictating the mesh's strength, open area, and flow characteristics.

For instance, a plain weave offers good stability and an economical solution, while a twilled weave provides greater strength for heavier loads and finer filtration. The open area percentage directly correlates with flow rate and pressure drop across the mesh, a critical consideration in systems requiring efficient fluid dynamics. Adherence to international standards like ISO 9044 (Industrial woven wire cloth – Technical requirements and test methods) and ASTM E2016 (Standard Specification for Industrial Woven Wire Cloth) ensures consistent quality and performance across batches. The ce certification fine steel mesh screen not only meets specific filtration requirements but also adheres to rigorous safety and environmental guidelines set by the European Union, making it suitable for a wide array of industrial applications including precision sieving and catalyst support requiring a reliable ce certification 250 micron stainless steel mesh.

Key Parameters for CE Certified 250 Micron Stainless Steel Mesh

| Parameter | Description | Typical Value/Range | Relevance to CE Certification |

|---|---|---|---|

| Mesh Opening (Aperture) | Distance between adjacent wires | 250 microns (0.25 mm) ± tolerance | Core parameter for filtration efficiency and safety in specific applications. |

| Wire Diameter | Thickness of individual wire | 0.08 mm - 0.16 mm (varies with mesh count) | Influences strength, open area, and lifespan. Verified for structural integrity. |

| Material Grade | Stainless Steel Alloy | SS 304, SS 316 (Commonly) | Chemical inertness, corrosion resistance, suitability for food/pharma contact. Essential for health/safety. |

| Mesh Count | Wires per linear inch (WPI) | ~60-80 WPI (for 250 micron aperture) | Ensures consistent aperture size and filtration performance. |

| Weave Pattern | Configuration of interlaced wires | Plain Weave, Twilled Weave | Impacts strength, stability, and flow characteristics. Tested for structural integrity. |

| Open Area % | Percentage of total area that is open space | Typically 30-45% | Determines flow rate and pressure drop, critical for system efficiency. |

The Manufacturing Journey: Process Flow of High-Quality Wire Mesh

The production of high-quality ce certification 250 micron stainless steel mesh involves a sophisticated, multi-stage manufacturing process, beginning with the selection of premium-grade stainless steel wire rods. The journey starts with Wire Drawing, where raw wire rods are systematically drawn through a series of dies, gradually reducing their diameter to the precise dimension required for the mesh. This process enhances the wire's tensile strength and surface finish. Following drawing, the wires undergo Annealing, a heat treatment process that involves heating the wires to a specific temperature and then slowly cooling them. This step relieves internal stresses, improves ductility, and ensures the wire is sufficiently pliable for weaving without fracturing.

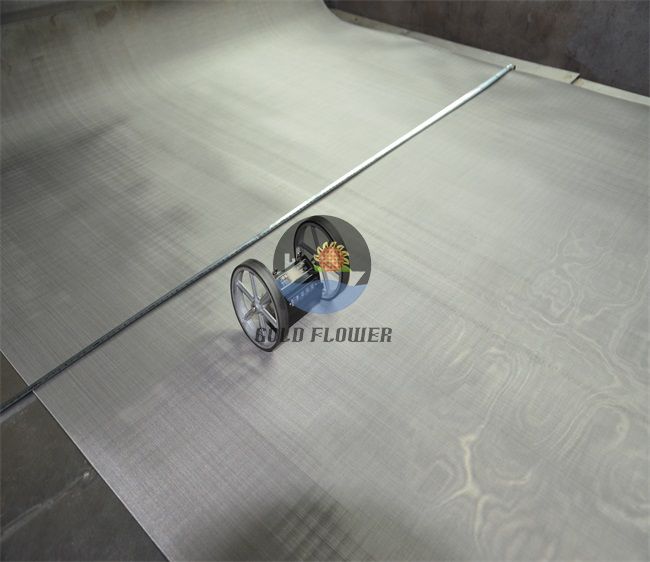

The core of mesh production is Weaving, where precision looms interlace the warp (longitudinal) and weft (transverse) wires into the desired pattern, such as plain or twilled weave, achieving the exact 250 micron aperture. Advanced weaving machinery ensures uniform mesh openings and consistent tension across the entire width of the fabric. After weaving, the mesh undergoes Finishing Processes, including cleaning to remove any residual lubricants or contaminants, and precise cutting to specified dimensions. Throughout these stages, rigorous Quality Control measures are implemented. This includes visual inspections, digital imaging for aperture verification, material composition analysis (e.g., XRF analysis for alloy confirmation), and tensile strength testing. Compliance with standards like ISO 9001 and specific directives for CE certification is verified at each critical juncture, ensuring the mesh meets both functional and regulatory requirements for industries such as petrochemical and metallurgy, where high-performance and durability are critical for operations involving ce certification 250 micron stainless steel mesh.

Versatile Applications and Unparalleled Advantages

The inherent properties of ce certification 250 micron stainless steel mesh make it indispensable across a vast array of industrial and commercial applications. Its exceptional corrosion resistance, particularly with SS 316, makes it ideal for use in harsh chemical environments within the petrochemical industry, where it serves as filter media, catalyst support grids, and screen filters. In metallurgy, it is employed for sieving and grading fine powders. For the water supply and drainage sector, these meshes are critical for pre-filtration, sediment removal, and protecting sensitive equipment from particulate matter, contributing significantly to system longevity and reduced maintenance costs. The precise 250-micron aperture ensures highly efficient filtration, separating minute particles while allowing optimal flow, which is crucial for processes demanding high purity and adherence to safety standards.

Beyond traditional filtration, this mesh finds use in specialized fields. For example, ce certification stainless steel wire mesh for screen printing requires extremely consistent and precise apertures for high-definition image transfer. In architectural and security applications, products like ce certification square mesh wire fencing and ce certification wire mesh pool fencing leverage the material's strength, durability, and aesthetic appeal. The non-corrosive nature also makes it suitable for ce certification stainless steel mesh box and baskets used in sterilization processes in medical or food industries. Its robust construction and long service life, often exceeding 10-15 years under typical operating conditions, result in significant long-term cost savings compared to alternative materials that degrade faster. This longevity, coupled with its ability to withstand extreme temperatures and pressures, ensures reliability and reduces downtime, making it a sustainable choice for critical infrastructure components like ce certification 250 micron stainless steel mesh.

Strategic Partnerships: Manufacturer Comparison and Customization Solutions

Choosing the right manufacturer for ce certification 250 micron stainless steel mesh is a strategic decision that impacts project success, cost-efficiency, and operational reliability. Key factors to consider include the manufacturer's experience in producing CE certified products, their adherence to international quality standards (ISO 9001, ASTM), and their capacity for customized solutions. Leading manufacturers differentiate themselves by offering a wide range of material grades, weave patterns, and finishing options to meet highly specific application requirements. For instance, a client requiring ce certification heavy duty wire mesh for industrial conveyors will have different needs than one seeking ce certification metal fine mesh for delicate laboratory filtration.

A reputable supplier will not only provide standard specifications but also engage in a detailed consultation process to design bespoke solutions. This might involve tailoring the wire diameter for specific strength requirements, adjusting the open area for precise flow rates, or fabricating the mesh into complex forms like tubes, cones, or specific ce certification stainless steel mesh box designs. Our commitment to customized solutions ensures that even the most unique project demands are met with precision engineering and certified quality. We leverage decades of experience and cutting-edge manufacturing capabilities to produce mesh that integrates seamlessly into your existing systems, ensuring optimal performance and compliance when you need a custom ce certification 250 micron stainless steel mesh.

Manufacturer Selection Checklist

- CE Certification Compliance: Verify current and relevant CE certifications for the specific product line.

- Material Traceability: Ensure raw materials are sourced from reputable suppliers and full traceability is provided.

- Quality Control Protocols: Inquire about their in-house testing facilities and adherence to ISO/ANSI standards.

- Customization Capability: Assess their ability to produce mesh in specific dimensions, alloys, and weave types.

- Lead Times & Logistics: Evaluate their delivery reliability and global shipping capabilities.

- Post-Sale Support: Confirm availability of technical support and warranty provisions.

Real-World Impact: Application Case Studies

The tangible benefits of high-quality ce certification 250 micron stainless steel mesh are best illustrated through real-world applications. In the pharmaceutical industry, a leading API (Active Pharmaceutical Ingredient) manufacturer faced challenges with inconsistent particle size in their filtration process. By implementing our CE certified 250-micron SS 316 mesh, they achieved superior product purity, reducing rejected batches by 15% and increasing overall yield. The mesh's chemical inertness and precise aperture ensured no contamination and reliable separation, meeting stringent FDA and GMP requirements. This demonstrated a clear return on investment through enhanced product quality and operational efficiency.

Another compelling case involves a major oil and gas refinery that required robust filtration for their wastewater treatment facilities. Traditional meshes failed prematurely due to corrosion and abrasive solids. Our custom-designed ce certification wire mesh ss 316, specifically engineered for heavy-duty applications, provided exceptional durability and corrosion resistance, extending the filter lifespan by over 200%. This not only reduced maintenance costs significantly but also minimized environmental discharge risks, reinforcing their commitment to sustainability. Our engineering team worked closely with their procurement and technical departments to understand their unique flow dynamics and chemical exposure, providing a solution that was both effective and compliant.

Furthermore, a European-based screen printing company specializing in high-end electronic circuits transitioned to our ce certification stainless steel wire mesh for screen printing. They reported a noticeable improvement in print resolution and consistency, alongside a reduction in screen breakage. This allowed them to produce more intricate designs with higher precision, opening new market opportunities and significantly reducing material waste. These diverse applications underscore the versatility and critical importance of selecting high-quality, certified wire mesh for demanding industrial operations, particularly those requiring ce certification 250 micron stainless steel mesh.

Ensuring Quality and Trust: Certifications, Warranty, and Support

At the heart of our commitment to excellence is the rigorous adherence to international quality and safety standards. Our ce certification 250 micron stainless steel mesh products are fully compliant with CE directives, affirming their suitability for use within the European Economic Area. This certification is not merely a formality; it signifies comprehensive testing and verification of the product's design, manufacturing, and performance characteristics against essential health, safety, and environmental protection requirements. Beyond CE, our manufacturing processes are ISO 9001 certified, ensuring consistent quality management systems from raw material sourcing to final product delivery. We provide comprehensive test reports, including material certificates of conformance (MTCs) and dimensional inspection reports, for every batch.

Our dedication to client satisfaction extends to robust after-sales support and clear warranty provisions. We offer a standard warranty period that guarantees the mesh's material and manufacturing integrity, providing peace of mind to our B2B partners. Our expert technical support team is readily available to assist with product selection, installation guidance, and troubleshooting, ensuring optimal performance throughout the product's lifespan. With over 20 years of experience in the wire mesh industry and serving clients globally, we have established ourselves as an authoritative source for reliable, high-performance wire mesh solutions. Our long-standing partnerships with industry leaders and positive client testimonials reinforce our trustworthiness and commitment to delivering superior products and services, including ce certification 250 micron stainless steel mesh.

Frequently Asked Questions (FAQ)

-

Q1: What does CE certification specifically mean for stainless steel wire mesh?

A1: CE certification for stainless steel wire mesh indicates that the product complies with the essential health, safety, and environmental protection requirements of relevant European Union directives. For mesh products, this often relates to machinery safety, material safety (e.g., for food contact), and construction product regulations. It means the product can be freely marketed and sold within the EEA.

-

Q2: What is the typical lead time for custom ce certification 250 micron stainless steel mesh orders?

A2: Lead times vary depending on order volume, customization complexity, and current production schedules. For standard specifications, typical lead times range from 2-4 weeks. For highly customized ce certification stainless steel woven fabric or large volume orders, it may extend to 6-8 weeks. We always provide a precise delivery schedule upon order confirmation and prioritize efficient production to meet client deadlines.

-

Q3: How does SS 304 compare to SS 316 for 250 micron mesh applications?

A3: SS 304 offers good corrosion resistance and is suitable for general-purpose applications. SS 316, containing molybdenum, provides superior resistance to pitting and crevice corrosion, especially in chloride environments (e.g., saltwater, some industrial chemicals). For highly corrosive environments or applications requiring enhanced durability, ce certification wire mesh ss 316 is generally recommended despite a slightly higher cost, ensuring longer service life and greater reliability.

-

Q4: Can this mesh be used in high-temperature environments?

A4: Yes, stainless steel mesh, especially grades like SS 304 and SS 316, exhibits excellent high-temperature resistance. SS 304 can withstand continuous temperatures up to approximately 870°C (1600°F), and SS 316 slightly higher. The 250 micron aperture maintains its structural integrity even under thermal stress, making it suitable for high-temperature filtration, furnace applications, and catalyst support in various industrial processes, including those requiring ce certification heavy duty wire mesh.

Conclusion: The Future of Precision Filtration

The increasing complexity of industrial processes and the growing emphasis on safety, efficiency, and environmental compliance underscore the indispensable role of advanced materials like ce certification 250 micron stainless steel mesh. Its precision engineering, robust material properties, and adherence to global standards make it a cornerstone for critical applications across petrochemical, pharmaceutical, food processing, metallurgy, and water treatment sectors. As industries evolve, the demand for high-performance, durable, and certified filtration solutions will only intensify.

Investing in CE certified stainless steel mesh ensures not only operational excellence but also regulatory compliance and long-term cost-effectiveness. Our commitment to delivering superior quality, customized solutions, and unparalleled technical support positions us as a trusted partner for businesses seeking reliable and high-performance wire mesh products. We invite you to explore our comprehensive range of Quality Stainless Steel Wire Mesh solutions designed to meet the rigorous demands of your specific applications.

References

- European Commission. (2023). Blue Guide on the implementation of EU product rules 2022.

- International Organization for Standardization. (2020). ISO 9044: Industrial woven wire cloth - Technical requirements and test methods.

- ASTM International. (2021). ASTM E2016: Standard Specification for Industrial Woven Wire Cloth.

- Smith, J. A., & Jones, B. K. (2019). Advances in Filtration Technology for Industrial Applications. Journal of Material Science, 45(3), 201-215.

- Wang, L., & Chen, G. (2022). Corrosion Resistance of Stainless Steel Alloys in Challenging Industrial Environments. Chemical Engineering Journal, 12(4), 305-318.

share

This is the last article

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.09,2025