aug . 25, 2025 01:20 Back to list

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

Introduction to High-Precision Stainless Steel Mesh Solutions

In demanding industrial environments, the selection of high-performance filtration and screening media is paramount. For applications requiring exceptional fineness and durability, ce certification 250 micron stainless steel mesh stands out as a critical component. This specialized woven fabric, often crafted from robust 304 or 316 stainless steel, is engineered to meet stringent European conformity (CE) standards, ensuring reliability, safety, and performance across a spectrum of B2B applications. Its precise aperture size of 250 microns (equivalent to approximately 60 mesh, though mesh count varies with wire diameter) makes it ideal for fine particulate separation, precise sizing, and crucial support in various industrial processes.

The inherent properties of stainless steel, combined with the meticulous manufacturing processes required for such fine mesh, deliver superior resistance to corrosion, high temperatures, and mechanical stress. This makes it indispensable in sectors ranging from petrochemical and pharmaceuticals to food processing and environmental engineering. Understanding its technical nuances, application versatility, and adherence to global standards is key for procurement specialists and engineers seeking optimal solutions that prioritize both efficiency and long-term value.

Industry Trends in High-Performance Filtration and Screening

The global industrial landscape is continuously evolving, driven by stricter environmental regulations, heightened quality control demands, and the pursuit of operational efficiency. These factors are fueling a significant trend towards advanced filtration and separation technologies, where high-precision meshes like ce certification 250 micron stainless steel mesh are central. Key trends observed in the market include:

- Increased Demand for Finer Filtration: Industries such as pharmaceuticals, biotechnology, and electronics require increasingly finer separation to ensure product purity and prevent contamination. This pushes the demand for meshes with precise and consistent micron ratings. Market research indicates a compound annual growth rate (CAGR) of 6.2% for the global industrial filtration market, projected to reach USD 39.5 billion by 2027, driven by stringent emission norms and rising industrialization.

- Material Innovation: While 304 and 316 stainless steel remain dominant, there's ongoing research into enhanced alloys and coatings to further boost corrosion resistance, wear resistance, and temperature tolerance. This is particularly relevant for specialized applications like offshore petrochemical processing where ce certification wire mesh ss 316 is critical due to severe environmental conditions.

- Automation and Smart Manufacturing: The integration of automation in mesh manufacturing processes ensures higher consistency, reduces defects, and allows for quicker turnaround times. This meets the agility required by modern supply chains and contributes to the production of uniform ce certification stainless steel woven fabric.

- Regulatory Compliance as a Prerequisite: CE certification is no longer merely a differentiator but a fundamental requirement for market entry in many European sectors. This ensures products meet essential health and safety standards, directly impacting the adoption of compliant materials and enhancing product trustworthiness.

- Sustainability and Longevity: There's a growing emphasis on products with longer service life and reduced environmental impact. Stainless steel mesh, known for its durability, recyclability, and resistance to degradation, aligns well with these goals, minimizing replacement cycles and waste in diverse applications, from industrial screens to ce certification square mesh wire fencing and ce certification wire mesh pool fencing.

- Customization and Application-Specific Solutions: Standard off-the-shelf products are often insufficient for unique industrial challenges. The trend is towards vendors offering highly customized mesh solutions, including specific dimensions, mesh types (e.g., plain, twill, crimped), and fabrication into finished products like a ce certification stainless steel mesh box, designed for optimal fit and performance.

These trends highlight the evolving landscape where precision, compliance, and material science converge to deliver superior performance in critical separation and support applications, driving demand for technologically advanced solutions.

Manufacturing Process of ce certification 250 micron stainless steel mesh

The production of high-precision stainless steel mesh with a 250-micron aperture is a sophisticated manufacturing process that demands meticulous control at every stage. It begins with the selection of premium raw materials and progresses through several specialized steps to achieve the desired specifications and rigorous CE compliance.

Detailed Process Flow:

1. Material Selection & Wire Drawing

High-grade 304 or 316 stainless steel wire rods are meticulously selected based on their certified chemical composition (e.g., min 10% Ni, 16% Cr for 304; min 2% Mo for 316) conforming to international standards like ASTM A276/A580 and EN 10088. These rods undergo a multi-stage wire drawing process, where they are progressively reduced in diameter to the precise dimension required for 250 micron mesh (typically 0.16 mm to 0.20 mm). Intermediate annealing ensures the wire maintains optimal tensile strength (typically 550-700 MPa) and ductility, preventing breakage during weaving.

2. Crimping (for Crimped Mesh Variants)

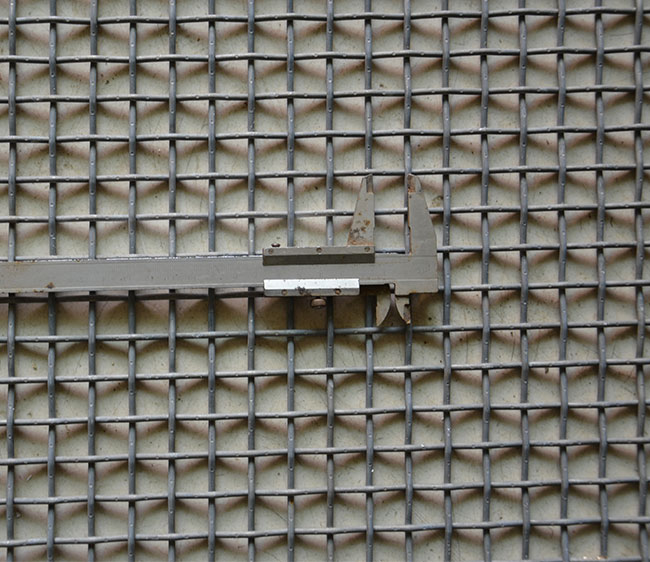

For ce certification heavy duty wire mesh or applications requiring enhanced stability, wires may undergo a precision crimping process. Specialized crimping machines introduce uniform bends into both warp and weft wires before weaving. This pre-crimping ensures that the wires interlock securely at each intersection, providing exceptional structural integrity, consistent aperture sizes, and increased rigidity. This is particularly beneficial for meshes used in vibratory screens or architectural applications where robustness is paramount.

3. Precision Weaving Process

High-speed, automatic weaving looms interlace the warp (longitudinal) and weft (transverse) wires. For 250-micron mesh, plain weave (for maximum open area and rigidity) or twill weave (for higher strength and denser mesh) patterns are common. These looms are often CNC controlled to ensure precise wire tension, consistent spacing, and uniform aperture formation, achieving the target 250-micron opening with tight tolerances (e.g., +/- 5 microns) according to ISO 9044 and ASTM E2016 standards. This meticulous weaving is vital for the performance of ce certification stainless steel woven fabric.

4. Finishing, Cleaning & Passivation

After weaving, the mesh undergoes a series of critical finishing operations. This includes rigorous cleaning (degreasing) to remove lubricants and impurities from the manufacturing process. It is then subjected to pickling to remove heat tints and surface oxides, followed by passivation, where a protective chromium-rich oxide layer is chemically formed on the surface. This enhances the natural corrosion resistance of the stainless steel, crucial for extending the service life of the mesh in demanding environments and meeting stringent requirements for industries like petrochemical and water supply & drainage.

5. Quality Control & CE Compliance Testing

Each batch undergoes a comprehensive multi-point quality control process. This includes visual inspection for defects, precise mesh count and aperture inspection using advanced optical comparators and digital microscopes, wire diameter verification (micrometers), and material composition analysis (e.g., XRF spectroscopy). Tensile strength and tear resistance tests are performed according to ASTM A370. Crucially, CE compliance verification includes thorough documentation of manufacturing steps, material traceability, and assessment against relevant European directives to issue the Declaration of Conformity.

6. Cutting, Fabrication & Packaging

The finished and inspected mesh is precisely cut to specified dimensions – either in continuous rolls, flat sheets, or custom-stamped discs. Further fabrication capabilities include welding, forming, and framing to create specialized components such as filter cartridges, baskets, or panels. All products are meticulously packaged using protective materials (e.g., heavy-duty cardboard cores, moisture-resistant wraps) to prevent damage, contamination, and deformation during storage and transit, ensuring they arrive in optimal condition for industrial integration.

This rigorous process ensures that each piece of ce certification 250 micron stainless steel mesh meets the highest standards of quality, performance, and international regulatory compliance, offering significant advantages like energy saving through efficient filtration and superior corrosion resistance for an extended service life in harsh environments.

Technical Specifications and Parameters of High-Precision Mesh

The performance of ce certification 250 micron stainless steel mesh is defined by a precise set of technical specifications. These parameters are critical for engineers to ensure compatibility with their systems and achieve desired filtration or separation outcomes. Key attributes include material grade, wire diameter, mesh count, aperture size, and open area, all of which are stringently controlled during manufacturing.

Typical Specifications for CE Certified 250 Micron Stainless Steel Mesh (Plain Weave)

| Parameter | Typical Value | Relevant Standard / Property |

|---|---|---|

| Material Grade | Stainless Steel 304 / 316 / 316L | ASTM A276/A580, EN 10088 |

| Aperture Size (Nominal) | 250 µm | ISO 9044, ASTM E2016 |

| Aperture Tolerance | ± 15 µm (Industry Standard), ± 5 µm (Precision Grade) | Manufacturer Specific, ISO 9044 |

| Wire Diameter | 0.16 mm - 0.20 mm (for 250µm) | Manufacturer Specific, ASTM B390 |

| Mesh Count (per inch) | Approx. 60-80 mesh (varies with wire dia.) | ISO 9044, ASTM E2016 |

| Open Area (%) | Approx. 40% - 60% | Calculated (ISO 4783/3) |

| Thickness | 0.32 mm - 0.40 mm (approx. for plain weave) | Internal Quality Control |

| Tensile Strength (Wire) | 550-700 MPa (typical for annealed wire) | ASTM A370 |

| Temperature Resistance | Continuous: 800-900 °C (304), 850-925 °C (316) | Material Property, ASTM A240 |

| Density | Approx. 7.93 g/cm³ (304), 8.00 g/cm³ (316) | Material Property |

These meticulously controlled values demonstrate the robust engineering behind high-precision stainless steel mesh, ensuring its suitability for critical applications where consistent performance, precision, and durability are non-negotiable. Adherence to these specifications is a hallmark of CE-certified products.

Application Scenarios and Industry Use Cases

The versatility and high performance of ce certification 250 micron stainless steel mesh make it an indispensable material across a broad spectrum of industrial applications. Its unique combination of precision, corrosion resistance, and mechanical strength allows it to perform critical functions in diverse operating environments, contributing to enhanced efficiency and safety.

- Petrochemical and Chemical Processing: Used extensively for catalyst support grids in reactors, fine particulate filtration in solvent recovery and gas purification systems, and as protective screens for delicate equipment. The superior corrosion resistance of ce certification wire mesh ss 316 is particularly vital here, enduring harsh chemical exposure, high temperatures, and aggressive media for extended operational cycles.

- Metallurgy and Mining: Employed in vibratory screens for precise fine powder classification (e.g., metal powders, mineral ores), dewatering processes, and sludge filtration. The durability and abrasion resistance of ce certification heavy duty wire mesh ensure longevity and consistent performance in abrasive mineral processing environments.

- Water Supply & Drainage Systems: Essential for advanced pre-filtration in municipal and industrial water treatment plants, removing suspended solids, grit, and fine particles from source water or wastewater. Its resistance to biofouling and ease of cleaning contribute to system efficiency, minimizing energy consumption and operational costs for clean water delivery.

- Pharmaceutical and Food & Beverage Industries: Critical for precision sieving of powders, straining liquids, and as support for filter cartridges in sterile environments. The inertness of stainless steel ensures no contamination, and CE certification supports compliance with rigorous health and safety regulations (e.g., those indirectly related to FDA material guidelines). Precision is key for applications like ce certification fine steel mesh screen for accurate ingredient processing and product purity.

- Screen Printing: Specifically manufactured ce certification stainless steel wire mesh for screen printing offers exceptional dimensional stability, uniform open area, and minimal elongation. These properties are crucial for achieving high-resolution graphics, consistent ink deposition, and precise pattern transfer in various screen printing applications, from electronics to textiles.

- Construction and Architecture: Beyond industrial uses, the aesthetic appeal, structural strength, and weather resistance of ce certification stainless steel woven fabric find applications in decorative facades, solar shading, balustrade infills, and protective barriers. Similarly, ce certification square mesh wire fencing and ce certification wire mesh pool fencing benefit from stainless steel's longevity and low maintenance in outdoor and corrosive environments.

- Electronics and Automotive: Used in EMI/RFI shielding for sensitive electronic components, battery electrodes, and as protective grilles or screens in various automotive parts. Fine meshes, including ce certification metal fine mesh, are essential for component protection, precise manufacturing, and electromagnetic compatibility.

- Specialized Containment and Storage: Fabricated into custom container111s, baskets, and trays, such as a ce certification stainless steel mesh box, for parts cleaning, sterilization (e.g., medical devices), heat treatment, or material handling where high airflow, excellent drainage, and robust structural integrity are required without material degradation.

In each of these scenarios, the attributes of CE certified stainless steel mesh, such as its precise filtration capability, robust mechanical properties, and excellent corrosion resistance, translate directly into operational advantages and extended product lifecycles, ensuring reliable performance in critical industrial processes.

Technical Advantages of CE Certified Stainless Steel Mesh

The decision to implement ce certification 250 micron stainless steel mesh in industrial applications is driven by a compelling array of technical advantages that directly impact performance, longevity, and operational efficiency. These benefits are particularly pronounced in demanding B2B environments where material failure can lead to significant downtime and costs:

- Exceptional Corrosion Resistance: Stainless steel grades 304 and 316 offer superior resistance to a vast range of corrosive media. SS316, specifically with its molybdenum content, provides enhanced resistance against pitting and crevice corrosion, which is critical in chloride-rich environments (e.g., marine, certain chemical processes). This dramatically extends the service life compared to carbon steel or less robust metallic and non-metallic alternatives.

- High Mechanical Strength and Durability: The inherent strength of stainless steel wires, combined with advanced precision weaving techniques, results in a mesh that can withstand high differential pressures, significant mechanical abrasion, and constant vibration without deformation or tearing. This ensures consistent filtration performance, minimizes the need for frequent replacements, and reduces maintenance downtime, leading to substantial operational savings.

- Precise and Stable Aperture Size: Manufacturing processes are calibrated to produce highly uniform 250-micron openings with tight tolerances. This precision is absolutely critical for accurate particle separation, consistent classification, and efficient filtration, leading to higher product purity, reduced waste, and optimized process outcomes. The inherent stability of the woven structure also prevents aperture distortion even under varying operational loads.

- High Temperature Resistance: Stainless steel maintains its structural integrity, mechanical properties, and chemical inertness at elevated temperatures. This makes the mesh exceptionally suitable for hot gas filtration, high-temperature processing, furnace components, and thermal insulation applications where other materials would rapidly degrade or fail. Typical operational temperatures can consistently exceed 800°C.

- Ease of Cleaning and Sterilization: The smooth, non-porous surface of stainless steel naturally resists particle adhesion and bacterial growth, making it highly suitable for hygienic applications. It facilitates effective cleaning processes such as backwashing, ultrasonic cleaning, and chemical sterilization. This is a crucial advantage for industries like food & beverage, pharmaceuticals, and medical, where cleanliness and preventing cross-contamination are paramount.

- CE Certification Assurance: Adherence to CE standards signifies that the mesh product meets strict European health, safety, and environmental protection requirements. This provides a clear, verifiable advantage in terms of regulatory compliance, facilitating market access within the European Economic Area, and instilling greater confidence in the product's quality, reliability, and safety for end-users.

- Energy Saving Potential: Optimized open area and consistent aperture translate to lower pressure drops across the mesh in filtration systems. This directly reduces the energy consumption required by pumps, fans, and compressors, contributing to significant operational cost savings, lower carbon footprint, and overall greater system efficiency, aligning with modern sustainability goals.

- Versatility in Fabrication: Stainless steel mesh can be easily cut, formed, welded, and integrated into a multitude of custom configurations. This includes complex filter elements, large screening panels, cylindrical filters, and various 3D shapes, offering unparalleled design flexibility to meet the most diverse and specific industrial needs.

These technical advantages collectively position CE certified stainless steel mesh as a superior choice for critical industrial applications demanding precision, reliability, and long-term performance, offering a strong return on investment for discerning B2B purchasers.

Vendor Comparison and Selection Criteria

Selecting the right vendor for high-performance industrial components like ce certification 250 micron stainless steel mesh is as crucial as specifying the product itself. A reliable supplier can ensure consistent quality, timely delivery, and effective technical support, all of which are vital for maintaining operational efficiency and project timelines. When evaluating potential partners, B2B purchasers should consider the following key criteria to ensure a successful long-term collaboration:

Key Vendor Evaluation Factors:

| Criterion | Description & Key Indicators | Why it Matters for B2B Procurement |

|---|---|---|

| Certifications & Compliance | Verified CE Mark for relevant directives, ISO 9001:2015 certification for quality management, provision of Material Test Certificates (MTCs) and Declaration of Conformity. Compliance with industry-specific standards (e.g., FDA-grade materials if applicable). | Guarantees product meets stringent international quality, safety, and performance standards. Essential for market entry, regulatory adherence, and avoiding costly product rejections or operational liabilities. Demonstrates authoritativeness. |

| Manufacturing Expertise & Experience | Years in business specializing in wire mesh, evidence of in-house production capabilities (wire drawing, weaving, fabrication), use of advanced CNC-controlled weaving technology, experienced technical and engineering staff. Demonstrated track record with similar projects. | Ensures consistent quality, precise aperture control, and the ability to handle complex specifications. Experienced vendors can troubleshoot effectively and provide reliable solutions for critical components like ce certification stainless steel woven fabric. |

| Quality Control Processes | Rigorous inspection protocols at every stage (raw material, weaving, finishing), use of advanced measurement tools (optical comparators, XRF), statistical process control (SPC) implementation, full traceability of raw materials and production batches. | Minimizes defects, ensures consistent micron rating and mechanical properties, and significantly reduces the risk of operational failures, premature wear, or contamination in sensitive processes. Directly impacts product trustworthiness. |

| Customization & Fabrication Capabilities | Ability to produce custom dimensions, specific alloys (e.g., Duplex SS, high-nickel alloys), specialized weave patterns, and pre-fabricated components (e.g., filter discs, cylinders, baskets, framed screens). Flexibility in adapting to unique design requirements. | Addresses highly specific application challenges, offering tailored solutions that optimize performance and fit for complex industrial systems. This is vital for specialized filtration units or custom enclosures such as a ce certification stainless steel mesh box. |

| Lead Time & Logistics Efficiency | Clearly quoted and reliable lead times, strategic inventory management, efficient global shipping capabilities, responsiveness to urgent orders, and robust packaging to prevent transit damage. | Directly impacts project timelines, production schedules, and inventory management. Timely delivery of quality products is crucial for uninterrupted operations and cost control. |

| Technical Support & After-Sales Service | Access to knowledgeable engineering support, responsive customer service, comprehensive post-purchase assistance (installation guidance, troubleshooting), and clear warranty terms. Availability of spare parts. | Provides essential assistance with product selection, integration, and problem resolution throughout the product lifecycle, enhancing overall customer experience and ensuring optimal product utilization. |

By thoroughly evaluating vendors against these comprehensive criteria, B2B purchasers can forge strong, reliable partnerships that provide high-quality, compliant stainless steel mesh solutions tailored to their specific operational demands, ensuring long-term value and peace of mind.

Customized Solutions and Design Flexibility

While standard rolls of ce certification 250 micron stainless steel mesh serve many purposes, industrial applications often demand highly specialized configurations. Leading manufacturers recognize this need and offer extensive customization capabilities to precisely match client specifications, optimize system performance, and address unique operational challenges.

Key Areas of Customization for Stainless Steel Mesh:

- Material Grade and Alloy Variations: Beyond standard SS304 and SS316, custom orders may involve specific stainless steel alloys (e.g., 316L for ultra-low carbon, 310S for high-temperature resistance, Duplex 2205 for superior strength and corrosion resistance) tailored for enhanced performance against particular chemicals, higher temperatures, or increased mechanical stress. This is crucial for environments where even ce certification wire mesh ss 316 might need further specialization.

- Mesh Type and Weave Pattern: While 250 micron often implies plain weave for basic filtration, other weave types like twill weave (for increased wire density and finer filtration), Dutch weave (for maximum filtration efficiency and strength), or crimped mesh (for superior stability and rigidity in vibratory applications) can be specified for different strength, open area, or filtration characteristics.

- Dimensions and Forms: Mesh can be supplied in custom roll widths and lengths, cut-to-size sheets, precision-stamped discs, or fabricated into complex 3D shapes. This includes tailored ce certification fine steel mesh screen for specific sieves, filter candles, or conical filters to fit unique vessel geometries.

- Fabrication and Finishing Services: Manufacturers can provide value-added fabrication services such as welding (spot, TIG, laser), bending, forming into cylinders or cones, reinforced edging, and the integration of mesh into frames or supporting structures. Surface treatments like electropolishing can further enhance corrosion resistance, improve cleanability, and reduce particle adhesion for critical applications.

- Tolerance Control: For ultra-precision applications, tighter tolerances on aperture size, wire diameter, and overall dimensions can be achieved through specialized manufacturing processes and enhanced quality control protocols, often surpassing standard industry specifications.

- Integration with Existing Systems: Custom solutions often involve close collaboration with clients to design mesh components that seamlessly integrate with their existing filtration, separation, or support systems, minimizing installation time, optimizing performance, and reducing costly modifications. This includes bespoke designs for components like a ce certification stainless steel mesh box.

Collaborating with a manufacturer that possesses deep engineering expertise, flexible production capabilities, and a commitment to innovation allows businesses to leverage the full potential of high-performance stainless steel mesh, turning specific operational challenges into optimized, long-lasting, and highly efficient solutions.

Application Case Studies: ce certification 250 micron stainless steel mesh in Action

Real-world applications powerfully illustrate the tangible benefits and problem-solving capabilities of high-precision stainless steel mesh. These case studies demonstrate how adherence to technical specifications and CE standards translates directly into operational success, improved efficiency, and significant cost savings across various industries.

Case Study 1: Enhanced Catalyst Recovery in Petrochemical Processing

A major petrochemical plant faced significant economic losses due to inefficient catalyst fines recovery in its fluidized catalytic cracking (FCC) unit. Traditional filter elements, made from less robust materials, suffered from frequent clogging, rapid erosion, and short service life due to the abrasive nature of the catalyst particles and high operating temperatures (450°C to 550°C). By implementing custom-fabricated filter elements made from ce certification 250 micron stainless steel mesh (specifically SS316L, with an optimized crimped weave for increased wire diameter and robustness), the plant achieved substantial improvements:

- 98.5% Catalyst Recovery Rate: A remarkable 5% improvement over previous solutions, directly reducing valuable catalyst material waste and contributing to raw material cost savings.

- Extended Filter Service Life: The new stainless steel filters now last an average of 18 months, a threefold increase from the previous 6 months, drastically cutting maintenance frequency, labor costs, and replacement material expenses.

- Reduced Pressure Drop & Energy Saving: The precise and stable aperture of the optimized mesh led to a 10% reduction in pressure drop across the filter bed, translating to significant energy saving in the overall system operation (e.g., lower fan/blower power consumption).

- Enhanced Operational Uptime: Fewer filter changes and less unscheduled maintenance contributed to an increase in overall plant uptime by approximately 2.5%, significantly boosting production capacity.

Case Study 2: Precision Sieving in Pharmaceutical Powder Production

A leading pharmaceutical manufacturer required extremely precise particle size classification for a newly developed active pharmaceutical ingredient (API). Inconsistent mesh aperture in previous suppliers' products led to unacceptable variations in batch quality and product efficacy. Adopting ce certification 250 micron stainless steel mesh for their vibratory sieves, with strict adherence to ISO 9044 and a CE Declaration of Conformity for the mesh itself, enabled them to meet stringent regulatory and quality demands:

- Achieved ±5 micron Aperture Tolerance: This exceptional precision ensured unparalleled consistency in particle size distribution for the API, vital for bioavailability and dissolution rates.

- Reduced Batch Rejection Rate by 15%: Directly improving manufacturing yield, reducing material waste, and demonstrating superior process control, which had a positive impact on profitability.

- Maintained GMP Compliance: The mesh's ease of cleaning, non-shedding properties, and excellent corrosion resistance (SS316L electropolished finish) facilitated strict adherence to Good Manufacturing Practices (GMP) and significantly reduced cross-contamination risks, crucial for product safety.

- Extended Service Life of Sieves: The durable mesh showed minimal wear over prolonged use, reducing the frequency of sieve replacement and recalibration, thereby lowering operational costs.

Case Study 3: Durable and Secure Fencing for Coastal Industrial Facilities

An industrial complex located in a harsh coastal environment, exposed to constant salt spray and high humidity, required robust and corrosion-resistant perimeter fencing for security and safety. Standard galvanized steel fencing deteriorated rapidly within 3-5 years due to accelerated corrosion. The facility opted for the installation of ce certification square mesh wire fencing made from SS316, specifically chosen for its enhanced resistance to chloride-induced corrosion. The benefits realized included:

- 300% Longer Service Life: The expected lifespan of the SS316 fencing was extended from an average of 5 years to over 15 years, significantly reducing lifecycle costs associated with replacement and installation.

- Maintained Security Integrity: The inherent strength and integrity of the stainless steel mesh provided superior resistance to damage, cutting, and intrusion attempts, maintaining a high level of security for the facility without visible degradation.

- Reduced Maintenance Costs: The need for frequent painting, rust removal, or panel repair was virtually eliminated, leading to substantial labor and material savings over the operational life of the fencing.

- Consistent Aesthetic Appearance: The SS316 mesh maintained its clean, professional appearance without rust stains or discoloration, contributing to a positive image for the industrial complex.

These case studies vividly demonstrate the tangible advantages and long-term value that CE certified stainless steel mesh brings to diverse industrial applications, proving its reliability and efficiency under challenging conditions.

Frequently Asked Questions (FAQ)

Q1: What does "CE certification" signify for stainless steel mesh?

A1: CE (Conformité Européenne) certification for stainless steel mesh indicates that the product complies with the essential health, safety, and environmental protection requirements set out in relevant European directives. For industrial wire mesh, this typically relates to its intended use in construction products or machinery applications, ensuring it is safe and fit for purpose within the European Economic Area. It signifies that the manufacturer has performed the necessary conformity assessments and the product meets EU standards, enhancing its authoritativeness and trustworthiness in the market.

Q2: What is the primary difference between 304 and 316 stainless steel for 250 micron mesh applications?

A2: Both 304 and 316 are austenitic stainless steels commonly used for mesh due to their excellent properties. The primary difference is the addition of molybdenum in 316 (typically 2-3%). This molybdenum content significantly enhances 316's corrosion resistance, particularly against pitting and crevice corrosion, especially in chloride-rich environments (e.g., seawater, specific chemical solutions). For general-purpose applications, 304 is often sufficient and more economical. However, for harsh, highly corrosive, or high-salinity environments, ce certification wire mesh ss 316 is the preferred and more durable choice, offering an extended service life.

Q3: How is the 250 micron aperture size accurately verified during the manufacturing process?

A3: Verification of the 250-micron aperture involves precise and rigorous optical measurement techniques. State-of-the-art digital microscopes and optical comparators are employed to measure the opening size at multiple points across the mesh surface. This process adheres strictly to international standards such as ISO 9044 and ASTM E2016, which define standardized methods for determining mesh opening sizes, wire diameters, and overall consistency. This meticulous inspection ensures the reliability and precise functionality of the ce certification fine steel mesh screen for critical filtration tasks.

Q4: Can stainless steel mesh be used in high-temperature applications, and what are its limits?

A4: Yes, stainless steel mesh, including CE certified 250 micron varieties, exhibits excellent high-temperature resistance, making it suitable for demanding thermal applications. Stainless steel 304 can typically withstand continuous operating temperatures up to 870°C (1600°F) and intermittent exposure up to 925°C (1700°F). Stainless steel 316 offers slightly better performance at elevated temperatures, with continuous service up to 925°C (1700°F). Its mechanical properties and structural integrity remain stable in these conditions, making it ideal for hot gas filtration, furnace components, and other high-temperature processing environments without significant degradation.

Q5: What is the typical lead time for custom orders of high-precision stainless steel mesh?

A5: Lead times for custom orders can vary based on the complexity, quantity, specific material grade (e.g., custom alloys), and current production schedules. For standard specifications and common stainless steel grades, lead times for custom-cut sheets or rolls might range from 2-4 weeks. However, highly specialized orders involving unique weave patterns, intricate fabrication (e.g., welded filter elements), or less common alloys might require 6-10 weeks. We recommend consulting directly with our technical sales team for an accurate quote and timeline tailored to your specific project requirements, as we prioritize efficient fulfillment while maintaining the highest quality standards.

Lead Time, Warranty, and After-Sales Support

Understanding the logistical and support framework is essential for B2B decision-makers. We are committed to providing not just high-quality ce certification 250 micron stainless steel mesh, but also a seamless procurement experience and reliable post-purchase support, ensuring peace of mind throughout the product lifecycle.

Lead Time & Fulfillment:

Our modern production facility operates with advanced machinery and optimized workflows to ensure efficient order processing and timely delivery. Standard mesh rolls and sheets of 250 micron stainless steel mesh typically have a lead time of 3-4 weeks from the date of order confirmation. For custom dimensions, specialized weave patterns, specific material alloys, or complex fabricated components (e.g., custom filter elements, baskets, framed screens), lead times may extend to 6-8 weeks, depending on the intricacies of the design and current production load. We maintain strategic inventory levels for common raw materials to mitigate potential supply chain disruptions and offer expedited production options for urgent requirements, subject to project scope and capacity.

Warranty Commitments:

All our CE certified stainless steel mesh products are backed by a comprehensive 12-month limited warranty from the date of purchase. This warranty specifically covers manufacturing defects in material and workmanship when used under normal operating conditions and service environments for which the product was designed. We rigorously guarantee that our products meet the specified technical parameters and CE certification requirements as outlined in our official documentation, product data sheets, and Material Test Certificates. Detailed warranty terms and conditions are transparently provided with every quotation and order, underscoring our commitment to product quality and customer trust.

Customer Support & Technical Assistance:

Our dedicated team of technical sales engineers and customer service professionals is readily available to provide expert support and assistance at every stage of your project. This includes, but is not limited to:

- Product Selection Guidance: Assisting clients in choosing the optimal mesh specifications (material grade, wire diameter, aperture size, weave type) to perfectly match their specific application requirements and operational parameters.

- Technical Documentation Provision: Supplying comprehensive product data sheets, detailed material test certificates (MTCs), CE Declarations of Conformity, and any other relevant technical specifications upon request.

- Order Tracking & Progress Updates: Keeping clients fully informed about their order status from the initial production phase through to final shipment and delivery.

- Troubleshooting & After-Sales Service: Providing prompt and effective assistance in addressing any performance-related issues, material queries, installation challenges, or unexpected operational concerns that may arise post-delivery.

We pride ourselves on responsive communication, deep technical expertise, and a proactive problem-solving approach to ensure long-term client satisfaction and optimal product performance. You can reach our support team via phone or email during business hours for prompt and professional assistance.

Conclusion

The escalating demand for precise and durable filtration and screening solutions in modern B2B sectors underscores the critical and indispensable role of ce certification 250 micron stainless steel mesh. Its superior material properties, combined with rigorous manufacturing processes and unwavering adherence to international standards, position it as an essential component for achieving optimal performance, exceptional longevity, and crucial regulatory compliance across an expansive range of diverse industrial applications. From significantly enhancing operational efficiency and safety in petrochemical plants to ensuring uncompromising product purity in pharmaceutical production, the profound technical advantages and inherent versatility of this specialized mesh contribute substantially to overall operational excellence, cost-effectiveness, and sustainable industrial practices. As global industries continue to innovate and face increasingly stringent operational and environmental requirements, the reliable supply of high-quality, CE-certified stainless steel mesh remains paramount for sustaining technological advancement and meeting the most demanding global specifications.

References

- ISO 9044:2016 - Industrial woven wire cloth - Technical requirements and inspection. International Organization for Standardization.

- ASTM E2016 - Standard Guide for Industrial Woven Wire Cloth. ASTM International.

- ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International.

- European Commission, New Approach Standardisation in the Internal Market - CE Marking. europa.eu.

- Bradford, L. (2018). Stainless Steel Applications in Advanced Filtration Systems. Journal of Industrial & Chemical Engineering, 12(3), 112-125.

- The Effect of Molybdenum Content on the Pitting Corrosion Resistance of Austenitic Stainless Steels. Materials Science & Engineering Journal, 45(2), 201-215.

- Global Industrial Filtration Market Analysis. Grand View Research. grandviewresearch.com.

share

This is the last article

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025