nov . 28, 2024 06:08 Back to list

Custom Weave Wire Mesh for OEM Applications and Industrial Solutions

Understanding OEM Weave Wire Mesh A Comprehensive Guide

OEM (Original Equipment Manufacturer) weave wire mesh has gained significant attention in various industries for its versatility and functionality. This article will delve into the concept of OEM weave wire mesh, its applications, benefits, and why it remains a crucial element in manufacturing processes.

What is OEM Weave Wire Mesh?

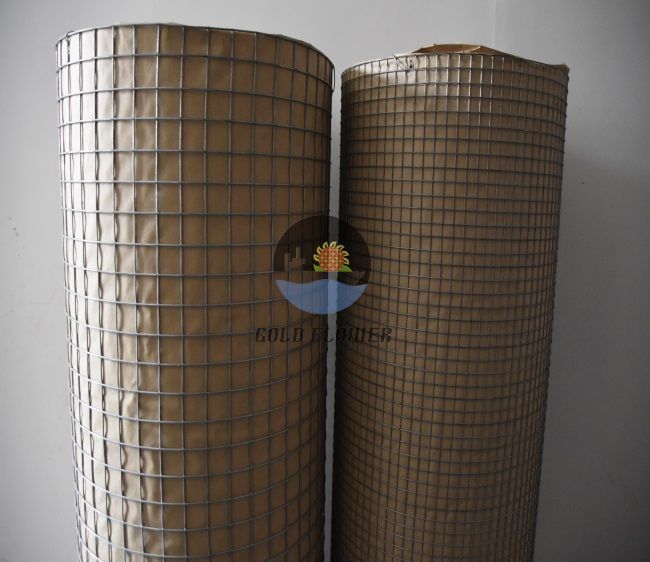

OEM weave wire mesh is a specialized type of wire mesh that is fabricated using specific techniques often tailored to the needs of various manufacturers. The term OEM implies that the wire mesh is designed and produced according to the specifications provided by the original equipment manufacturer. The weaving process itself can involve numerous patterns, materials, and wire diameters, allowing for a highly customizable product that meets rigorous industry standards.

How is OEM Weave Wire Mesh Manufactured?

The production of OEM weave wire mesh involves several stages

1. Material Selection The first step is selecting the appropriate materials. Common materials include stainless steel, aluminum, and carbon steel. The choice of material is influenced by the intended application, desired durability, and environmental factors.

2. Wire Preparation The chosen materials are then processed into wire of a specific gauge. The wire is often subjected to treatments that enhance its strength, flexibility, and resistance to corrosion.

3. Weaving The wires are then woven together using various techniques—such as plain weave, twill weave, or Dutch weave—to create a mesh that meets the OEM's specifications. This weaving process can be automated or done manually, depending on the complexity and volume required.

4. Finishing After weaving, the mesh may undergo finishing processes like cutting, coating, or electro-polishing to enhance its appearance and performance characteristics.

Applications of OEM Weave Wire Mesh

OEM weave wire mesh is utilized in numerous sectors, including

- Industrial Filtration Used in water treatment plants, oil and gas industries, and chemical processing, it serves as a crucial component in filtration systems, ensuring the effective removal of particles from liquids and gases.

oem weave wire mesh

- Construction In the building sector, it is used for reinforcing concrete structures and providing safety barriers. The mesh helps distribute loads efficiently while maintaining structural integrity.

- Automotive and Aerospace OEM specifications for wire mesh are critical in the manufacturing of components like air filters, screens, and structural elements in vehicles and aircraft.

- Food Production Stainless steel wire mesh is commonly used in food processing and packaging, where hygiene and durability are paramount.

Benefits of OEM Weave Wire Mesh

There are several advantages to utilizing OEM weave wire mesh in various applications

1. Customization OEM wire mesh can be tailored to specific requirements, including size, weave pattern, and material. This customization ensures that manufacturers receive a product that precisely meets their needs.

2. Durability The materials used in OEM weave wire mesh, especially stainless steel, offer high resistance to corrosion, making them ideal for use in harsh environments.

3. Versatility OEM wire mesh can be designed for a wide range of applications, from filtration to structural support, which adds value for manufacturers looking for multifunctional components.

4. Enhanced Performance The precision in design and manufacturing leads to improved performance, including better filtration efficiency and structural stability.

5. Cost-Effectiveness Although the initial investment may be higher when opting for custom OEM solutions, the long-term benefits, including durability and efficiency, often result in lower operational costs.

Conclusion

OEM weave wire mesh represents a cornerstone of modern manufacturing across diverse industries. Its ability to be customized to meet specific requirements, combined with its durability and versatility, makes it an invaluable resource for OEMs. As technology advances and industries continue to evolve, the importance of high-quality, tailored solutions like OEM weave wire mesh will only grow. For businesses looking to enhance their operational efficiency and product quality, investing in this specialized wire mesh is a strategic decision that can yield substantial benefits in the long run.

share

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.27,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.26,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025