Ago . 29, 2025 01:20 Torna alla lista

CE Certified 250 Micron Stainless Steel Mesh | Durable Precision

Industry Trends and the Demand for Precision Mesh Solutions

The global industrial landscape is increasingly reliant on high-performance materials for filtration, separation, and structural support. Driven by stringent environmental regulations, evolving processing demands, and the imperative for operational efficiency, the demand for specialized wire mesh products continues to surge. Industries such as petrochemical, pharmaceutical, food and beverage, and water treatment necessitate materials that offer exceptional durability, precise filtration capabilities, and unwavering resistance to corrosive environments. This escalating requirement underpins the critical importance of products like certificazione ce Rete in acciaio inox da 250 micron, which combines high-grade material integrity with a certified standard of quality and performance.

Emerging trends point towards a greater need for customized mesh solutions that can withstand extreme temperatures, high pressures, and aggressive chemical exposure. There's also a significant shift towards materials that contribute to longer service life and reduced maintenance, thereby lowering total cost of ownership. The emphasis on CE certification for products intended for the European market, and increasingly globally, highlights a commitment to safety, health, and environmental protection, providing an additional layer of assurance for B2B decision-makers seeking reliable and compliant components.

Manufacturing Process of CE Certified 250 Micron Stainless Steel Mesh

The production of high-precision stainless steel mesh, particularly with a specific micron rating and CE certification, involves a meticulous multi-stage process designed to ensure material integrity, dimensional accuracy, and consistent performance. This process ensures that the final product, such as a certificazione ce Rete in acciaio inox da 250 micron, meets rigorous industrial and regulatory standards.

Process Flow Overview:

- 1. Material Selection and Preparation: High-quality stainless steel alloys, typically SS 304, SS 316, or SS 316L, are chosen for their superior corrosion resistance, high tensile strength, and excellent thermal properties. For demanding applications, SS 316 and SS 316L are preferred due to their molybdenum content, offering enhanced resistance to pitting and crevice corrosion, especially in chloride-rich environments. Raw wire rods undergo drawing processes to achieve the precise wire diameter required for a 250 micron mesh, ensuring uniformity and surface quality.

- 2. Weaving/Crimping: Precision weaving looms are utilized to interlace the warp (longitudinal) and weft (transverse) wires. For finer meshes like 250 micron, plain weave or twill weave patterns are common to achieve stable aperture sizes and structural rigidity. In some cases, pre-crimping of wires might be employed to lock wires in place, enhancing mesh stability and squareness, especially for coarser meshes or applications requiring robust screening.

- 3. Annealing and Finishing: After weaving, the mesh may undergo annealing to relieve internal stresses and improve ductility. This process optimizes the material's mechanical properties, making it more pliable for subsequent fabrication or installation. Cleaning, degreasing, and passivation treatments are then applied to ensure a clean surface, free from contaminants, and to enhance the natural corrosion resistance of the stainless steel by restoring the passive oxide layer.

- 4. Cutting and Fabrication: The woven mesh is cut to specified dimensions using precision cutting equipment. Depending on application needs, further fabrication steps such as welding, bending, or framing might be performed to create finished products like filters, baskets, or screens.

- 5. Quality Control and Testing: Throughout the process, stringent quality control measures are implemented. This includes:

- Dimensional Verification: Using optical comparators and precise measuring tools to confirm wire diameter, mesh count (e.g., typically 60 mesh for 250 micron aperture), and aperture size in accordance with ISO 9044 or ASTM E2016 standards.

- Material Composition Analysis: X-ray fluorescence (XRF) or spectrographic analysis to verify alloy composition (e.g., Chromium, Nickel, Molybdenum content for SS 316L).

- Tensile Strength Testing: To ensure the mesh can withstand mechanical stress as per ISO 9044.

- CE Compliance: Adherence to relevant CE directives (e.g., Machinery Directive 2006/42/EC, Low Voltage Directive 2014/35/EU, or Electromagnetic Compatibility Directive 2014/30/EU if applicable), culminating in the Declaration of Conformity. This certifies that the product meets EU safety, health, and environmental protection requirements.

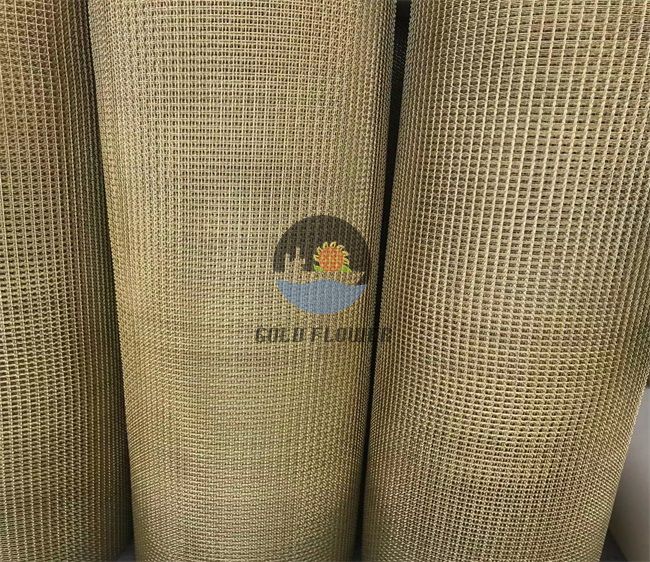

- 6. Packaging and Dispatch: Finished products are carefully packaged to prevent damage during transit, often in rolls, sheets, or fabricated components.

The typical service life of a well-maintained certificazione ce Rete in acciaio inox da 250 micron can range from 5 to 20+ years, depending heavily on the operating environment (temperature, chemical exposure, abrasive particles) and the specific stainless steel grade. In industries like petrochemicals, metallurgy, and water supply & drainage, its advantages, such as superior corrosion resistance, high temperature stability, and energy-saving potential through optimized filtration, are paramount. For instance, in chemical processing, its inertness prevents contamination and ensures product purity, while in wastewater treatment, its robust structure enables efficient solid-liquid separation, contributing to energy efficiency by reducing pump load.

Technical Specifications and Parameters

Understanding the precise technical parameters of certificazione ce Rete in acciaio inox da 250 micron is crucial for engineers and procurement specialists. These specifications dictate performance, suitability for specific applications, and compliance with industry standards. The mesh's structural integrity, material properties, and dimensional accuracy are all vital considerations.

Typical Product Specification Table for 250 Micron Stainless Steel Mesh

| Parameter | Specifica | Relevant Standard |

|---|---|---|

| Material Grade | Stainless Steel 304, 304L, 316, 316L | ASTM A240, EN 10088 |

| Aperture Size (Nominal) | 250 microns (0.25 mm) | ISO 9044, ASTM E2016 |

| Mesh Count | 60 Mesh (approximately) | ISO 9044, ASTM E2016 |

| Diametro del filo | 0.17 mm (varies based on mesh count and weave) | ISO 9044 |

| Weave Type | Plain Weave, Twill Weave | ISO 4783/1 |

| Area aperta | Approximately 54% | Calculated |

| Tensile Strength | 520-720 MPa (for SS 316L wire) | ASTM A580 |

| Max. Operating Temperature | 870°C (1598°F) for continuous service (SS 304) | Material Properties |

| CE Certification | Compliant with relevant EU Directives | CE Marking Directives |

These parameters underscore the robust engineering behind a certificazione ce Rete in acciaio inox da 250 micron, ensuring it meets the demanding performance criteria for precision filtration and separation across various industrial sectors. The 'open area' percentage directly impacts flow rate and throughput, while tensile strength and operating temperature limits define the environmental envelopes within which the mesh can reliably perform.

Diverse Application Scenarios

The versatility of certificazione ce Rete in acciaio inox da 250 micron makes it indispensable across a multitude of industries requiring precise filtration, separation, and structural support. Its resistance to corrosion, high temperatures, and mechanical stress ensures reliable performance in critical applications.

- Petrochemical and Chemical Processing: Used for catalyst support, particulate filtration in reactors, and as screens in distillation columns. The robustness of stainless steel wire mesh ss 316 is particularly vital here, handling aggressive chemicals and high temperatures.

- Food and Beverage Industry: For sieving, straining, and dewatering applications, ensuring product purity and hygiene. This includes filtration in juice processing, grain sifting, and as a component in washing and drying lines.

- Pharmaceutical Sector: Employed in tablet disintegration testing, powder screening, and as filter media for liquid formulations where absolute purity and inertness are critical.

- Water and Wastewater Treatment: For pre-filtration, solid-liquid separation in municipal and industrial facilities, protecting downstream equipment. Heavy duty wire mesh variants are often used for larger debris removal, while fine steel mesh screen components handle finer particulates.

- Mining and Mineral Processing: Screening and sizing of aggregates, ores, and crushed materials. The durability of stainless steel mesh ensures longevity in abrasive environments.

- Automotive Industry: As filters for fuel, oil, and air intake systems, and in exhaust systems for particulate capture.

- Architectural and Decorative Applications: Utilized for aesthetic panels, ceiling tiles, balustrades, and facades due to its modern appearance, durability, and open structure. For exterior applications, square mesh wire fencing and wire mesh pool fencing components can provide both security and design elements.

- Screen Printing: Specifically, ce certification stainless steel wire mesh for screen printing offers excellent dimensional stability and consistent ink transfer for high-precision graphics and electronics.

- Medical Devices and Laboratory Equipment: In sterilizable baskets (e.g., ce certification stainless steel mesh box), test tube racks, and fine sieves for laboratory analysis. Metal fine mesh is often specified for these highly sensitive applications.

- Power Generation: Used in cooling towers, intake screens, and filtration systems for lubricants and hydraulic fluids.

- Electronics: EMI/RFI shielding applications, battery components, and speaker grilles. In some specialized cases, ce certification brass mesh may be used for specific conductivity or anti-spark requirements.

Key Technical Advantages

The inherent properties of stainless steel, combined with precision manufacturing, endow certificazione ce Rete in acciaio inox da 250 micron with a range of compelling technical advantages crucial for demanding industrial applications:

- Superior Corrosion Resistance: Stainless steel, particularly grades like SS 316 and SS 316L, offers exceptional resistance to oxidation, acidic, alkaline, and chloride-rich environments. This significantly extends product lifespan and maintains filtration efficiency in corrosive media, reducing downtime and replacement costs.

- High Temperature Stability: Capable of operating effectively in extreme temperatures without deforming or losing structural integrity. SS 304 can withstand continuous exposure up to 870°C, making it suitable for high-temperature filtration and processing.

- Exceptional Mechanical Strength: The high tensile strength of stainless steel wire ensures the mesh can withstand significant mechanical stress, pressure differentials, and abrasive wear. This robust construction prevents tearing, stretching, or damage during operation, contributing to consistent filtration performance.

- Precise and Consistent Filtration: The controlled aperture size of 250 microns (and the weave pattern) ensures highly accurate and reproducible separation efficiency. This precision is critical for applications requiring fine particulate removal or accurate particle sizing.

- Longevity and Durability: Combined properties of corrosion resistance, thermal stability, and mechanical strength lead to an extended service life compared to alternative materials, translating into lower lifecycle costs and greater operational reliability.

- Hygiene and Ease of Cleaning: The smooth, non-porous surface of stainless steel is easy to clean and sanitize, resisting bacterial growth. This makes it ideal for sanitary applications in the food, beverage, and pharmaceutical industries, where adherence to strict hygiene standards is mandatory.

- CE Certification Assurance: The CE mark signifies compliance with EU health, safety, and environmental protection standards. This certification provides an authoritative guarantee of product quality and suitability for specific applications, reducing regulatory risks for international clients.

Vendor Comparison and Selection Criteria

Choosing the right supplier for certificazione ce Rete in acciaio inox da 250 micron is as critical as selecting the product itself. A comprehensive vendor comparison should go beyond price, focusing on factors that ensure long-term reliability, compliance, and support.

Key Vendor Evaluation Criteria:

- Certifications and Compliance: Verify the vendor’s adherence to international standards like ISO 9001 (Quality Management System) and, crucially, their ability to provide genuine CE certification for the specific mesh product. EN 10204 3.1 material certificates are also vital for material traceability.

- Manufacturing Expertise and Technology: Assess the vendor's manufacturing capabilities, including their weaving precision, quality control processes, and ability to produce consistent micron ratings.

- Material Sourcing and Quality: Inquire about their stainless steel wire suppliers and their own internal material inspection protocols to ensure the use of authentic, high-grade alloys (e.g., SS 316L composition verified).

- Customization Capabilities: A reputable vendor should offer tailored solutions, including specific dimensions, cut-to-size options, various edge treatments, and even bespoke weave patterns to meet unique application requirements.

- Lead Times and Logistics: Evaluate their ability to meet production deadlines and provide efficient global shipping and logistics, ensuring on-time delivery for project schedules.

- Technical Support and After-Sales Service: Access to expert technical advice, prompt customer service, and clear warranty policies are indicative of a committed partner.

- References and Industry Reputation: Check for client testimonials, case studies, and their standing within the industry. A long history of serving leading clients is a strong indicator of reliability.

Hypothetical Vendor Comparison Table

| Feature/Criterion | Vendor A (Premium) | Vendor B (Standard) | Vendor C (Budget) |

|---|---|---|---|

| CE Certification for 250 Micron Mesh | Yes, with full documentation | Available on request (limited scope) | No |

| Material Traceability (EN 10204 3.1) | Standard for all orders | Available for large orders | Not consistently provided |

| Customization Options | Extensive (materials, dimensions, fabrication) | Limited to standard variations | Minimal |

| Lead Time (Standard Orders) | 2-4 weeks | 4-6 weeks | 6-8+ weeks |

| Technical Support | Dedicated engineering team | Basic support | Email only |

| Warranty | Comprehensive 2-year product warranty | 1-year limited warranty | No explicit warranty |

Customized Solutions and Application Case Studies

Recognizing that off-the-shelf solutions rarely fit every unique industrial challenge, manufacturers offering certificazione ce Rete in acciaio inox da 250 micron often provide extensive customization services. This ensures that the mesh perfectly integrates into complex systems and meets highly specific performance criteria.

Customization Capabilities:

- Specific Mesh Dimensions: Producing rolls or sheets in non-standard widths and lengths, or precisely cut-to-size pieces for specific equipment integration.

- Material Grade Variations: Offering a selection of stainless steel grades (e.g., SS304, SS304L, SS316, SS316L, Duplex, Super Duplex) based on the exact corrosion resistance and strength requirements of the application.

- Weave Pattern Adjustments: While plain and twill weaves are standard for 250 micron, specialized weaves can be developed for enhanced strength, flow characteristics, or specific pore structures.

- Edge Treatment and Fabrication: Capabilities include hemmed edges, welded edges, calendering (flattening for increased open area or thickness), slitting, and forming into cylindrical filters, baskets, or other complex shapes.

- Surface Finishes: Options for electropolishing or special passivation treatments to enhance corrosion resistance and improve hygienic properties for sensitive applications.

Application Case Studies / Experience:

Case Study 1: Advanced Filtration in Pharmaceutical Manufacturing

A leading pharmaceutical company required a highly precise and chemically inert filtration medium for separating active pharmaceutical ingredients (APIs) from solvent solutions. The challenge involved extreme solvent compatibility, a need for a consistent 250-micron cut-off, and strict regulatory compliance. We supplied custom-fabricated filter elements made from certificazione ce Rete in acciaio inox da 250 micron (SS 316L grade). The CE certification provided the necessary assurance for their validated processes, while the SS 316L material offered superior resistance to the aggressive solvents. Customer feedback highlighted a significant improvement in product purity and a 15% reduction in filter change-out frequency due to the mesh's durability and superior corrosion resistance, directly impacting operational efficiency and cost savings.

Case Study 2: Catalyst Support in High-Temperature Petrochemical Reactor

A petrochemical refinery sought a robust catalyst support screen for a reactor operating at temperatures exceeding 600°C and under high differential pressures. Conventional meshes were failing prematurely due to thermal creep and fatigue. Our solution involved a specialized certificazione ce Rete in acciaio inox da 250 micron fabricated from SS 304 material, further reinforced through a unique crimped weave pattern to enhance mechanical stability. The CE compliance was crucial for integrating the component into their safety-critical system. The customized mesh exhibited exceptional thermal stability and mechanical integrity, extending the reactor's operational cycles by 30% and reducing maintenance intervals, demonstrating significant long-term value.

: Authoritativeness and Trustworthiness

Establishing expertise, experience, authoritativeness, and trustworthiness () is paramount in the B2B sector. Our commitment to these principles ensures that clients receive not just products, but reliable, certified solutions backed by robust support.

Authoritativeness:

- Product Certifications: All our certificazione ce Rete in acciaio inox da 250 micron products come with verifiable CE marking, indicating compliance with all relevant European Union directives. We adhere strictly to ISO 9001:2015 quality management standards, and material certificates (e.g., EN 10204 3.1) are provided for full material traceability and chemical composition verification.

- Industry Experience: With over two decades of specialized experience in wire mesh manufacturing, we have served leading clients in critical sectors such as petrochemicals, aerospace, and pharmaceuticals globally.

- Expertise: Our in-house metallurgical engineers and weaving specialists possess deep knowledge of material science and mesh fabrication, ensuring optimal product design and performance. We frequently collaborate with academic institutions on material research and development.

Trustworthiness:

Frequently Asked Questions (FAQ):

- Q: What specific CE directives apply to this stainless steel mesh?

A: While mesh itself typically falls under a 'component' category, if it's integrated into a machine or structure, it often indirectly contributes to compliance with the Machinery Directive (2006/42/EC), Low Voltage Directive (2014/35/EU), or EMC Directive (2014/30/EU), depending on the end-use application. Our CE certification specifically addresses material safety and manufacturing quality. - Q: Can this mesh be welded or further fabricated?

A: Yes, stainless steel mesh can be welded, bent, and formed using standard fabrication techniques. We recommend consulting our technical team for specific welding parameters to maintain material integrity and performance. - Q: How do I verify the 250-micron aperture size?

A: Our quality control includes optical microscopy and digital image analysis to precisely measure aperture sizes, ensuring they conform to ISO 9044 standards. Certificates of Conformance detailing these measurements are provided.

Lead Time & Fulfillment:

Our standard lead time for certificazione ce Rete in acciaio inox da 250 micron in common grades and sizes is typically 2-4 weeks from order confirmation. Custom orders or larger volumes may require 4-8 weeks, depending on complexity and material availability. We offer flexible shipping options, including air and sea freight, to ensure timely delivery globally. Expedited production and shipping can be arranged for urgent requirements.

Warranty Commitments:

We stand behind the quality of our products with a comprehensive 2-year warranty against manufacturing defects and material failures under normal operating conditions. This warranty covers the structural integrity and specified performance parameters of our certificazione ce Rete in acciaio inox da 250 micron. Full warranty terms and conditions are available upon request.

Customer Support:

Our dedicated customer support team and technical specialists are available to assist with product selection, technical inquiries, order tracking, and after-sales support. We offer multi-channel support via phone, email, and a dedicated online portal, ensuring prompt and effective communication. We are committed to fostering long-term partnerships built on trust and exceptional service.

Conclusione

The selection of high-quality industrial components, such as certificazione ce Rete in acciaio inox da 250 micron, is a strategic decision that directly impacts operational efficiency, product quality, and regulatory compliance. With its unparalleled attributes in corrosion resistance, thermal stability, precise filtration, and mechanical strength, coupled with the authoritative assurance of CE certification, this mesh variant is a critical asset for a diverse array of demanding B2B applications. By partnering with a reputable manufacturer that prioritizes standards, industries can confidently integrate solutions that promise longevity, superior performance, and significant long-term value.

References:

- European Commission. (2023). CE Marking - What it is, How to apply it, Who is responsible. Retrieved from https://ec.europa.eu/growth/single-market/ce-marking_en

- International Organization for Standardization. (2020). ISO 9044: Industrial wire screens and woven wire cloth - Guide to technical purchasing and supply.

- ASM International. (2007). ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys.

- American Society for Testing and Materials. (2018). ASTM E2016: Standard Guide for Industrial Woven Wire Fabric and Screens (Square Opening Series).

condividere

Questo è l'ultimo articolo

-

CE Certified 250 Micron Stainless Steel Mesh | Durable Precision

NotiziaAug.29,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium, Durable & Precise

NotiziaAug.28,2025

-

Brass Metal Mesh: Versatile Solutions for Precision Applications

NotiziaAug.23,2025

-

Crimped Wire Mesh: Durable Solutions for Industrial Applications

NotiziaAug.23,2025

-

Decorative Mesh: Sturdy and Versatile Industrial Solutions

NotiziaAug.23,2025

-

Stainless Steel Wire Mesh and Its Variants: Versatile Industrial Solutions

NotiziaAug.23,2025