Dic . 19, 2024 11:30 Back to list

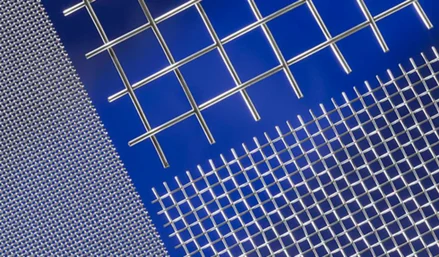

oem wire cloth screen

Understanding OEM Wire Cloth Screen A Comprehensive Overview

In the realm of industrial manufacturing and various applications, OEM wire cloth screens play a crucial role. These screens, made from woven wire mesh, are used extensively in countless applications, ranging from filtration and separation to reinforcement and support. In this article, we will delve into the characteristics, benefits, applications, and manufacturing processes of OEM wire cloth screens, shedding light on why they are an indispensable component in many industries.

What is OEM Wire Cloth Screen?

OEM stands for Original Equipment Manufacturer, indicating that the wire cloth screens are manufactured to meet the specific needs and standards set forth by the original client or producer of a product. Wire cloth screens consist of interwoven wires that form a grid-like structure, resulting in a versatile material that can vary in mesh size, wire diameter, and material composition. Common materials include stainless steel, carbon steel, and specialized alloys, which can be selected based on the application’s requirements.

Characteristics of OEM Wire Cloth Screens

1. Mesh Size The mesh size determines the size of the openings between the wires. This can range from very fine openings, capable of filtering out minute particles, to larger openings suitable for more significant separations.

2. Durability OEM wire cloth screens are designed to withstand mechanical stresses and are resistant to corrosion, especially those made from stainless steel.

3. Customizability These screens can be tailored according to specific requirements, including different wire diameters, mesh patterns, and dimensions. This customizability makes them ideal for specialized applications.

4. Versatility OEM wire cloth screens can be used in various environments, from oily and wet conditions to dry and abrasive situations, making them suitable for numerous industries.

Benefits of OEM Wire Cloth Screens

1. Enhanced Filtration The precision in manufacturing ensures that the screens provide superior filtration capabilities, efficiently separating particles according to specified sizes.

2. Increased Productivity By using high-quality OEM screens, businesses can optimize their processes, leading to enhanced operational efficiency and productivity.

3. Cost-Effectiveness Although the initial investment may be higher compared to generic options, the durability and performance of OEM wire cloth screens lead to reduced replacement costs and less downtime.

4. Improved Quality Control OEM manufacturers often implement stringent quality assurance measures, ensuring that every wire cloth screen meets the required specifications and standards.

Applications of OEM Wire Cloth Screens

oem wire cloth screen

The applications of OEM wire cloth screens are extensive

1. Mining and Mineral Processing Used for screening and separating valuable minerals from ores, reducing waste and improving recovery rates.

2. Construction Employed as reinforcement materials in concrete, as well as for sieving aggregates.

3. Food and Beverage Industry Utilized in filtration processes, these screens help remove unwanted particles from liquids and bulk solids, ensuring product quality and safety.

4. Pharmaceuticals In drug manufacturing, wire cloth screens are instrumental in ensuring the purity of products by removing contaminants.

5. Petrochemical Used in various filtration devices to separate particulates from liquids and gases in petrochemical processes.

Manufacturing Process

The manufacturing process of OEM wire cloth screens usually involves several steps

1. Material Selection Choosing the right material based on the application’s requirements for strength, corrosion resistance, and temperature tolerance.

2. Weaving Process The wires are woven together to create the desired mesh pattern. Various weaving techniques, such as plain weave or twill weave, can be employed depending on the required strength and flexibility.

3. Finishing Treatments Post-weaving treatments, including coatings or surface treatments, may be applied to enhance attributes like corrosion resistance or mechanical strength.

4. Quality Control Finally, rigorous testing is done to ensure that each screen meets the specified standards for mesh density, wire thickness, and overall durability.

Conclusion

In summary, OEM wire cloth screens are vital components across various industries, providing effective filtration, reinforcement, and separation solutions tailored to meet specific operational needs. Their customizable nature, combined with durability and versatility, make them a preferred choice for manufacturers and businesses looking to enhance productivity and efficiency. By understanding the specifications and applications of OEM wire cloth screens, industries can leverage their full potential, leading to superior product quality and operational success. Whether in mining, pharmaceuticals, or construction, these wire cloth screens represent a smart investment in maintaining high standards and achieving excellence in production processes.

share

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025