Ago . 20, 2025 10:16 Torna alla lista

Premium Mesh Solutions Engineered for Industrial Precision

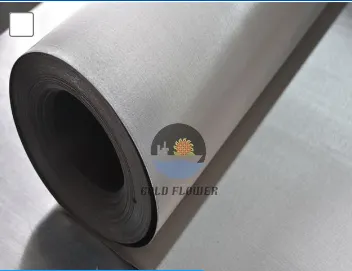

In modern industries where filtration, separation, and screening are central to operational performance, the demand for precision-engineered materials has never been higher. Among the most trusted and efficient options on the market today is dutch weave wire mesh, a high-density woven material recognized for its strength, tight aperture control, and exceptional flow filtration capabilities. As industries evolve and regulations become stricter, the selection of mesh materials is no longer a routine procurement—it is a strategic investment in performance and reliability. Our advanced dutch weave E dutch woven wire mesh products deliver consistent results, helping clients optimize processes across sectors ranging from pharmaceuticals and petrochemicals to aerospace and food manufacturing.

Understanding the Structural Advantages of Dutch Weave

The core of dutch weave lies in its unique configuration. Unlike traditional square mesh that prioritizes open area, Dutch-style weaving integrates a higher mesh count in one direction and a thicker wire in the other, creating a cloth with a wedge-shaped flow channel. This tightly woven structure allows dutch woven wire mesh to deliver enhanced mechanical strength and fine filtration capabilities without compromising on pressure handling.

The result is a mesh that can retain particles as small as a few microns, while maintaining stable flow rates and resisting clogging under continuous use. It is especially suitable for demanding applications such as oil filtration, water purification, pressure gas separation, and even fine powder sieving. Our production process ensures dimensional accuracy, surface flatness, and mechanical uniformity across all batches. With our high-performance dutch weave wire mesh, clients gain the confidence to operate in extreme environments where filtration efficiency directly impacts system safety and product quality.

Precision Engineering Meets Performance in Dutch Woven Wire Mesh

One of the most critical reasons for the industrial success of dutch woven wire mesh is its adaptability. Depending on the end-use application, it can be woven into plain Dutch, twill Dutch, or reverse Dutch patterns. Each variant delivers distinct benefits in terms of flow direction, strength, and particle retention. Our manufacturing facility is equipped with advanced looms that allow for tight control over weave density, wire diameter, and fabric thickness, enabling us to meet both standard and highly customized specifications.

Our dutch woven wire mesh is available in stainless steel grades such as 304, 316, and 316L, which ensures corrosion resistance in aggressive chemical or marine environments. This makes it an ideal solution for use in distillation columns, filtration cartridges, hydraulic filters, and pneumatic components. Our mesh also undergoes thorough tensile strength testing and porosity analysis before being released, guaranteeing that every roll we deliver upholds our strict quality assurance standards.

Reliable Wire Cloth Mesh for Cross-Industry Efficiency

Versatility is a core strength of wire cloth mesh, especially when used in industries that demand both structural integrity and performance under pressure. Our wire cloth is engineered for use in multiple settings, including automotive filtration systems, food processing sieves, chemical plant strainers, and gas separation units. Unlike single-use filter materials that degrade over time, our stainless steel wire cloth mesh offers excellent durability, ease of cleaning, and long-term reusability.

Every application requires a different approach, and we help clients choose the correct wire diameter, mesh count, and weave type to suit their needs. Whether you require mesh for high-volume liquid filtration or precision gas dispersion, we provide full technical consultation and rapid turnaround times on all customized orders. Our clients appreciate the confidence of working with a supplier that not only understands metallurgy and weave mechanics but also values production continuity and cost efficiency.

Why Leading Manufacturers Choose Dutch Weave Wire Mesh

For manufacturers in critical sectors, mesh failure is not an option. That’s why dutch weave wire mesh has become the material of choice for engineers and OEMs looking for consistent filtration performance. The controlled porosity and high tensile strength of Dutch weave ensures that the mesh can withstand both pulsating flows and constant high-pressure operations. Compared to alternative materials like polymer membranes or synthetic fiber mesh, Dutch weave delivers superior lifespan, minimal maintenance, and significantly lower total cost of ownership.

Moreover, the manufacturing quality of dutch weave wire mesh affects everything from energy consumption to product purity. That’s why we invest in top-grade raw materials, precision weaving equipment, and a rigorous quality assurance system to ensure that our clients receive mesh that meets or exceeds industry norms. Whether you need stock mesh panels or high-precision custom sheets, our Dutch weave products stand at the forefront of global industrial standards.

Dutch Weave Wire Mesh FAQs

What is the structural difference between Dutch weave and plain weave?

Dutch weave uses a combination of fine weft wires and thicker warp wires, creating a denser and more compact mesh structure than plain weave. This design enhances filtration efficiency and provides better mechanical stability, particularly in high-pressure or fine particle retention applications.

Which industries benefit most from using dutch woven wire mesh?

Rete metallica tessuta olandese is ideal for industries requiring precision filtration, such as pharmaceuticals, oil and gas, aerospace, water treatment, and chemical processing. Its durability and fine filtration capabilities make it suitable for both static and dynamic systems where contamination control is essential.

Can wire cloth mesh be used for both air and liquid filtration?

Absolutely. Our wire cloth mesh is manufactured with flexibility in mind. It performs well in both liquid and air filtration systems, maintaining integrity under pressure while ensuring efficient particle separation. It is widely used in ventilation filters, oil strainers, and fuel filtration units.

What are the benefits of using stainless steel dutch weave wire mesh?

Stainless steel dutch weave wire mesh offers exceptional corrosion resistance, mechanical strength, and thermal stability. These properties make it suitable for harsh environments, including marine applications, acidic filtration systems, and high-temperature industrial processes. It also supports reusability and long service life.

Is custom fabrication available for dutch weave mesh products?

Yes, we offer full customization services for dutch weave wire mesh. You can specify parameters such as weave type, wire diameter, mesh count, and dimensions. Our team works closely with clients to ensure that every order matches operational and technical requirements precisely.

condividere

-

Transforming Spaces with Christmas Tree Decorative Mesh and Architectural Mesh

NotiziaAug.20,2025

-

The Modern Appeal of Stainless and Steel Wire Cloth

NotiziaAug.20,2025

-

Reliable Solutions with SS 304 Mesh for Industrial

NotiziaAug.20,2025

-

Premium Mesh Solutions Engineered for Industrial Precision

NotiziaAug.20,2025

-

Precision Filtration with Wire Mesh Filter Elements

NotiziaAug.20,2025

-

Innovative Designs with Decorative Metal Mesh

NotiziaAug.20,2025