Gen . 06, 2025 18:59 Back to list

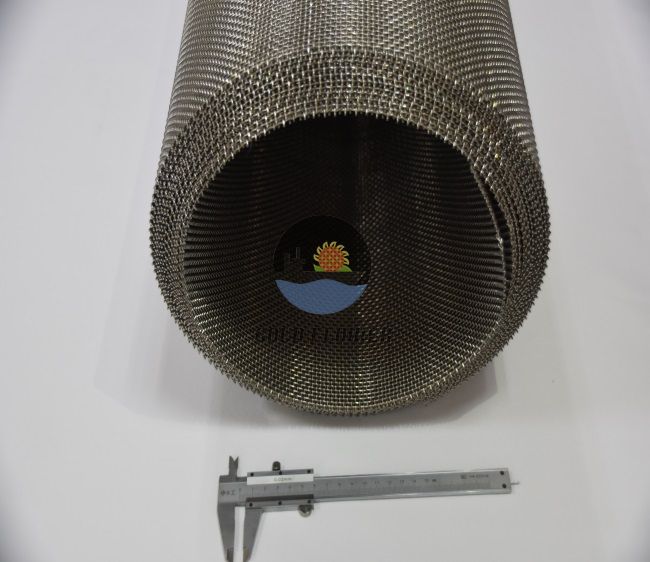

woven wire mesh filter

Wire mesh, a versatile and essential material in various industries, plays a pivotal role in enhancing structural integrity and safety. Renowned for its intricate design and durability, wire mesh is utilized in a multitude of applications, ranging from construction to agricultural projects. As an industry expert with years of experience, I delve into the multifaceted uses, advantages, and considerations when choosing high-quality wire mesh, ensuring reliable application and long-lasting results.

Wire mesh is celebrated for its robustness and ability to withstand environmental stress, making it an indispensable asset in construction. It's commonly used in reinforcing concrete structures, where it adds tensile strength, ensuring buildings can endure both weight and environmental pressures. Construction experts emphasize the importance of selecting the correct gauge and material—be it stainless steel, galvanized steel, or PVC-coated mesh—each offering unique properties suited for specific environmental conditions.

In agricultural settings, wire mesh serves as a protective barrier, safeguarding crops and livestock. Its use in fencing provides a secure environment against predators while ensuring ventilation and visibility. Experts advise on the appropriate mesh size and aperture to achieve the desired level of security without compromising on ventilation. Additionally, the ease of installation and maintenance positions wire mesh as a cost-effective solution, promoting sustainable agricultural practices.

Beyond construction and agriculture, wire mesh finds applications in industrial filtration systems. Its ability to filter out particulates while allowing the passage of gases and liquids is invaluable in processes ranging from petrochemical to food production. Precision in mesh size is crucial here, as it determines the efficiency and functionality of the filtration system. Industry insiders stress the need for high-quality materials to prevent contamination and ensure adherence to industry standards.

wire mesh

For those considering wire mesh for any application, understanding the material's expertise and authority becomes crucial. Consulting with knowledgeable suppliers can offer insights into the best materials and designs based on specific project requirements. This ensures not only the effectiveness of the wire mesh but also adheres to regulatory standards and safety protocols, enhancing trustworthiness in its application.

Furthermore, innovations in wire mesh technology have introduced advanced manufacturing techniques, such as laser cutting and precision welding, which enhance the product's structural integrity and aesthetic appeal. These advancements open up new possibilities in architectural design and artistic installations, where aesthetic considerations are as important as functionality. As a result, architects and designers can explore creative applications of wire mesh, driven by both artistic vision and practical utility.

In conclusion, wire mesh stands out as a dynamic and durable material, indispensable across various sectors. Its application in construction, agriculture, and industrial filtration underscores its versatility and reliability. For professionals seeking reliable outcomes, engaging with experienced suppliers and leveraging innovative manufacturing technologies are key strategies. These steps ensure the optimal selection and utilization of wire mesh, maintaining its standing as a trusted and authoritative choice in both functional and creative applications. As industries evolve, the adoption of wire mesh continues to expand, driven by its proven effectiveness and adaptability to meet ever-changing demands.

share

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025