Mar . 19, 2024 15:29 Back to list

Basics of Wire Mesh

Wire mesh is fabricated by the intertwining, weaving, or welding of wires of various thicknesses to create proportionally equal parallel rows and intersecting columns. Also known as wire fabric, wire cloth, or hardware mesh, the production of wire mesh involves the weaving of wire on industrial looms, leaving square or rectangular gaps between the wires. Welded wire mesh or fabric is manufactured using an electric welder that joins parallel longitudinal wires where the wires intersect.

There are a limitless number of shapes, sizes, and configurations of wire mesh made from an assortment of highly durable and resilient materials whose major function is to separate, screen, structure, and shield various applications and processes. The types of wire include galvanized steel, stainless steel, aluminum, steel, and copper alloy wire. The type of application, necessary tensile strength, durability, longevity, and required flexibility are some of the factors used to determine the desired type and style of wire.

How Wire Mesh is Made

The processes used to produce wire mesh are weaving and welding, with wire weaving being similar to the weaving of cloth on a loom, while welding is used to join the wires where they intersect. Both processes are completed using pre-programmed machines.

Wire Weaving

Near the end of the 17th century, woven wire cloth for the mining and pulp industries came into high demand, leading to the development of wire weaving looms. Over the centuries, the use for wire mesh has advanced beyond mines and pulp mills to architecture, plastic extrusion, aggregate screening, and filtration processing. The rise in demand has led to the modern industrial wire weaving industry.

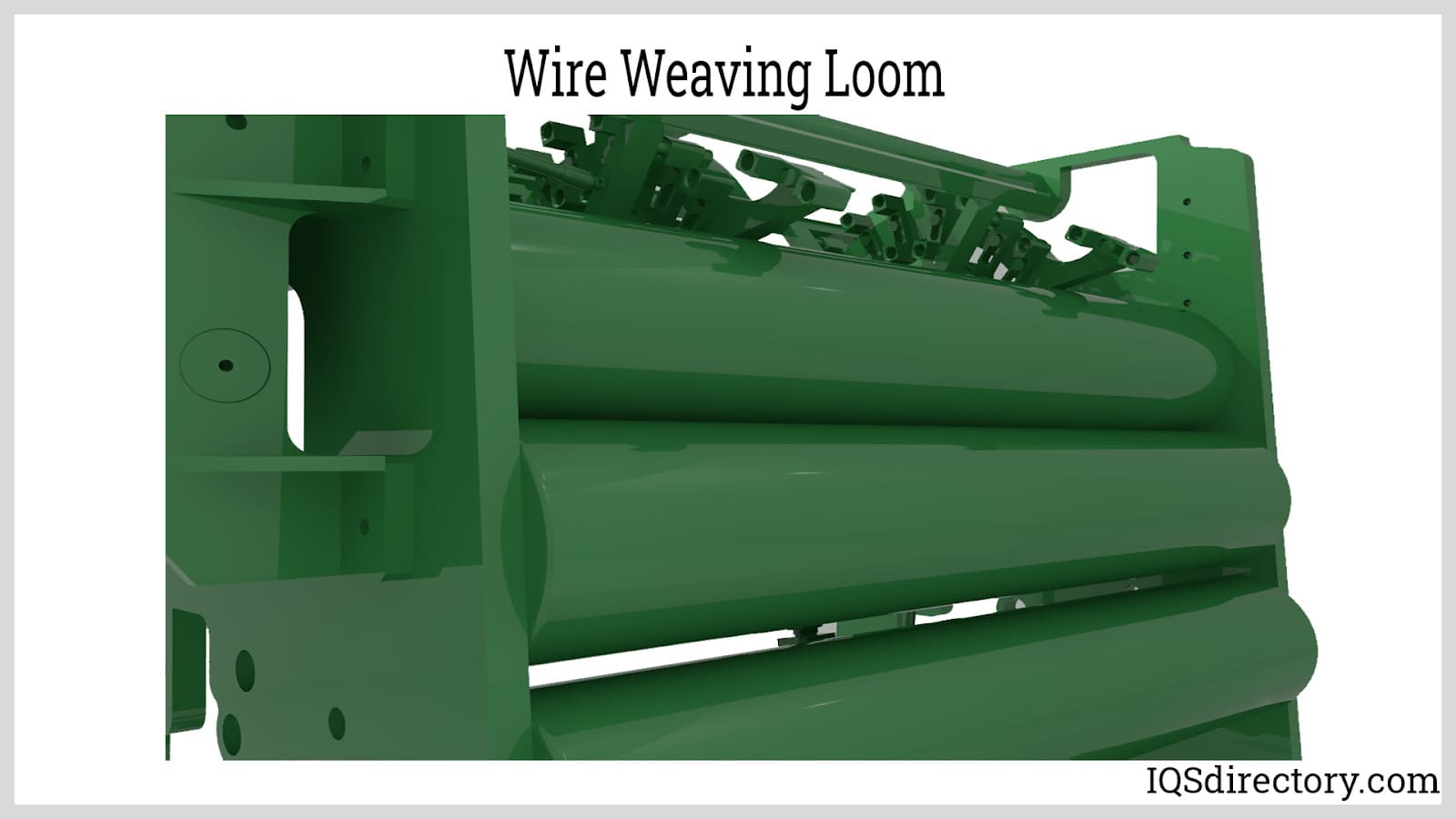

- Weaving Loom — Weaving looms weave mesh rolls with widths of 48”, 60”, 72”, 98”, or wider. The loom has a warp beam, heddle frames, a reed, a rapier for transporting weft wire, and a take-up mechanism.

Manufacturers use looms to weave meshes of standard and custom patterns. The completed mesh rolls are cut to varying lengths depending on the needs of customer specifications. Wires woven horizontally or lengthwise are warp wires, while wires woven vertically or crosswise are referred to as weft wires or shute wires, terms commonly used in textile manufacturing.

- Warp Beam — The warp beam is a cylindrical drum wrapped with the warp wires. The warp beam's tension must be meticulously controlled to avoid elongation of the woven mesh. The number of warp wires varies depending on the mesh width and must be kept the same length.

- Heddle Frames — The heddle frames separate the wires that are fed by the warp beam. Most looms have two heddle frames, with one used to lift half of the warp wires while the other pulls the warp wires down. The heddle frames change position as the weft wires move across the warp wires.

- Rapier Band — The weft wires are carried across the full width of the cloth by the rapier at each cycle of the heddle frame. It feeds a single weft wire between the sets of warp wires.

- Reed — The reed keeps the warp wires from the warp beam in place and accurately spaced and separated. Once the weft wire moves across the warp wires, the reed beats the weft wires tightly in place in the wire cloth.

- Take-Up — The take-up mechanism is a set of rollers that takes the fabric away from the loom with a pickup roller and two other rollers that work together to wind the cloth to the cloth roller. The fabric is wound in single layers with a smooth flat surface created by it being passed through the set of rollers.

Once the loom has been assembled and the warp beam loaded, the weaving process is completed automatically. As the loom begins, the warp beam unwinds in slow, even increments. In unison with the warp beam feeding the warp wire, the take-up mechanism winds the woven completed cloth in the same increments as the warp beam. The synchronized motion helps the loom maintain tension on the warp wires, which is a critical necessity for the production of high-quality cloth.

Welded Wire Mesh

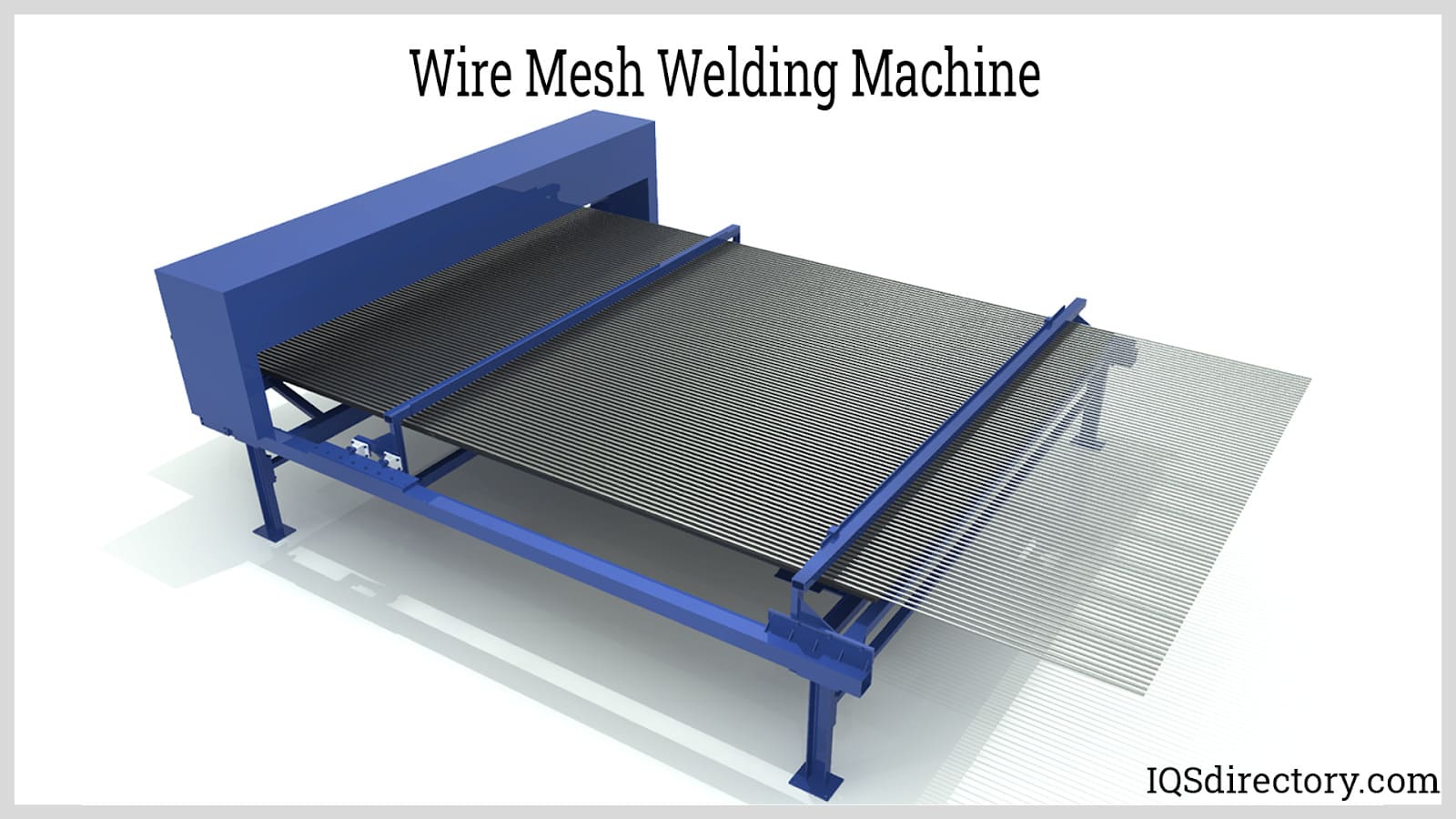

Wire mesh is welded using a semi-automatic process that welds the intersections of the woven wires. Welding machines are programmed to weld the intersections at the horizontal and vertical aligned wires. Several welding techniques are used to join the connections, including resistance welding, tungsten inert gas (TIG) welding, plasma welding, and soldering.

- Weld Mesh Machine — The process of wire mesh welding begins with feeding wires into a weld mesh machine, which is much like the heddle frames and reeds of wire weaving.

- Wire Spools — Separate spools of wire are fed through a straightener. Pre-cut wires that match the dimensions of the wire mesh are placed separately from the wires fed from the spools. Since the wires are coming off spools, whether pre-cut or fed from them, they are mechanically straightened to lay flat on the welding surface.

- Mechanical Placement — The pre-cut wires are laid flat across the wires being fed from the spools. The wires are perpendicular to each other at right angles in mesh welding.

- Welding — Once the wires are positioned, the programmed welding process begins and applies a uniform weld at each cross-section.

- Process Completion — The collection of the final wire mesh from the welding process can be in rolls, like wire weaving, or sheets that are trimmed to size and placed in piles of wire mesh panels.

Welded mesh is heavier, sturdier, and stronger than woven wire mesh and can only be used with thicker wires that are capable of withstanding the welding process. Since the wire is welded, it is more rigid and durable, which makes it ideal for fencing, cages, and concrete mesh sheets.

Types of Wire Mesh

The different kinds of wire mesh are classified by how they were made, their qualities, function, and weave patterns. Each of the various types is designed to meet the strength, weight, and finish requirements of a project or application. The determining factors regarding the type of wire mesh that will be used are its finish, type of metal, and type of pattern, with finish and metal being the major determining factors.

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025