Nov . 16, 2024 18:57 Back to list

Top Choices for High-Quality Industrial Screen Mesh Solutions

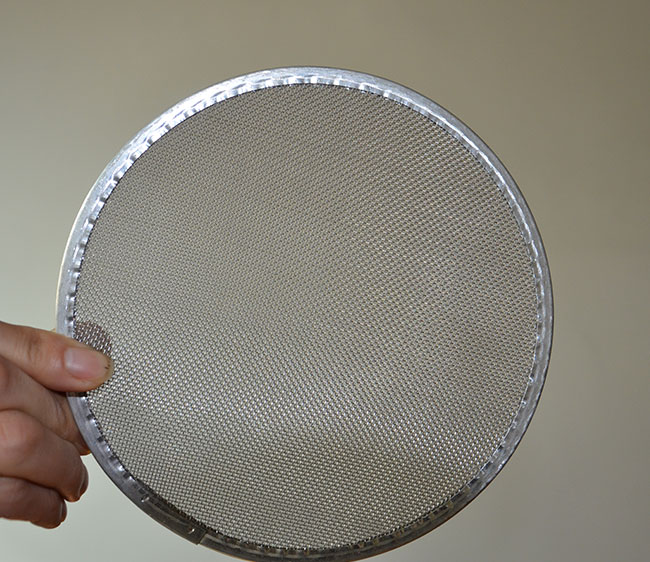

The Best Industrial Screen Mesh An Essential Component for Efficiency and Durability

In various industries, from construction to food processing, the importance of reliable and efficient screen mesh cannot be overstated. Industrial screen mesh serves as a vital barrier, responsible for filtering materials, separating particles, and ensuring the quality of products. With countless options available in the market, selecting the best industrial screen mesh can significantly enhance operational productivity and safety.

One of the primary considerations when choosing screen mesh is the material it is made from. Stainless steel mesh is highly regarded for its excellent durability and resistance to corrosion, making it suitable for environments exposed to moisture or harsh chemicals. Its robustness ensures a long service life, reducing the need for frequent replacements and maintenance. Conversely, polyester mesh is often favored in industries like food and beverage, where sanitation is paramount. This type of mesh offers ease of cleaning and maintains an excellent level of hygiene, critical for complying with health regulations.

Another critical factor is the mesh size and configuration. The ideal mesh size depends on the specific application it serves. For instance, a finer mesh is required for applications that involve small particles, whereas coarser mesh works well for larger aggregates. Precision in the mesh design can influence the efficiency of separation processes, which ultimately impacts productivity. Moreover, the weaving pattern of the mesh plays a significant role in determining its strength and flexibility. Different weaving methods—such as plain weave, twill weave, or Dutch weave—offer unique advantages and cater to various industrial requirements.

best industrial screen mesh

In addition to material and design, durability and resistance to wear are essential attributes of industrial screen mesh. In high-traffic and high-volume environments, the wear and tear on screen mesh can be significant, leading to operational delays and increased costs. Investing in high-quality mesh, designed to withstand heavy loads and abrasive materials, can significantly enhance operational longevity.

Furthermore, customization options are increasingly important in the industrial sector. Many manufacturers now offer screen mesh that can be tailored to specific dimensions, hole shapes, and wire diameters, aligning perfectly with unique operational needs. This level of customization ensures that industries can achieve optimal efficiency while minimizing waste.

In conclusion, selecting the best industrial screen mesh is crucial for enhancing productivity, maintaining quality, and ensuring safety in various industrial processes. From material choices and mesh sizes to durability and customization options, understanding these factors can help businesses make informed decisions. With the right industrial screen mesh, companies can optimize their operations and ensure that they are equipped for success in today's competitive environment.

share

-

Best Brass Wire Mesh Screen High Quality & OEM Custom

NewsJun.03,2025

-

Premium Fine Mesh Filters Discount Prices + Free Shipping

NewsJun.03,2025

-

Air Filter Dimensions High-Efficiency Filters for Compressors & ACs

NewsJun.03,2025

-

Premium Aluminum Fireplace Screens Durable & Stylish Safety Solutions

NewsJun.03,2025

-

Variable Valve Timing Oil Filter Screen - Durable OEM Replacement & Enhanced Filtration

NewsJun.03,2025

-

Premium Garbion Fence Exporter Durable Gabion Solutions & Products

NewsJun.02,2025