Feb . 15, 2025 06:33 Back to list

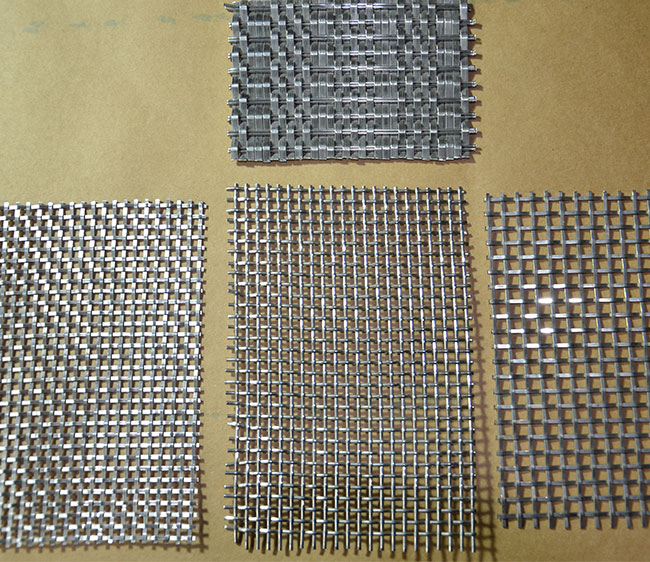

321 304 316Plain Dutch Weave Stainless Steel Wire Mesh

Dutch weave wire cloth stands as a pinnacle of precision and utility in industries where quality and reliability are non-negotiable. This specialized type of woven wire cloth is renowned for its unique weaving pattern, where the warp wires are heavier and lie closer together, while the shute wires are lighter, creating a dense and robust mesh. For those considering purchase options, understanding its application, benefits, and the expertise required to manufacture such a product can significantly impact your decision-making process.

In real-world applications, several industries have recounted positive experiences with Dutch weave wire cloth. For instance, in the chemical industry, users have reported significant improvements in filtration efficiency, leading to cleaner products and reduced processing times. This efficiency is attributed primarily to the wire cloth’s ability to withstand corrosive environments and maintain performance without frequent replacements. Similarly, in the aerospace sector, where precision and reliability are paramount, Dutch weave wire cloth is utilized in fuel filtration systems, ensuring that only the finest impurities are removed, thereby safeguarding engine components and enhancing the longevity of the machinery. Choosing the right Dutch weave wire cloth also involves considering the material composition. Stainless steel remains a popular choice due to its excellent corrosion resistance, durability, and strength, making it suitable for rigorous applications. However, variations such as Inconel or Hastelloy might be recommended based on specific environmental conditions such as extreme temperatures or chemical exposures. A knowledgeable supplier will advise on the optimal material selection based on your unique needs, adding another layer of expertise to the purchasing process. Ultimately, the decision to invest in high-quality Dutch weave wire cloth is one that promises long-term benefits, including greater efficiency, reduced maintenance costs, and enhanced product quality. By collaborating with a reputable and experienced manufacturer, you ensure that your investment delivers on its promises and positions your operations for success in a competitive landscape. Whether you're in the initial stages of product research or ready to make a purchase, prioritizing these factors will enable a choice that supports operational excellence and business growth.

In real-world applications, several industries have recounted positive experiences with Dutch weave wire cloth. For instance, in the chemical industry, users have reported significant improvements in filtration efficiency, leading to cleaner products and reduced processing times. This efficiency is attributed primarily to the wire cloth’s ability to withstand corrosive environments and maintain performance without frequent replacements. Similarly, in the aerospace sector, where precision and reliability are paramount, Dutch weave wire cloth is utilized in fuel filtration systems, ensuring that only the finest impurities are removed, thereby safeguarding engine components and enhancing the longevity of the machinery. Choosing the right Dutch weave wire cloth also involves considering the material composition. Stainless steel remains a popular choice due to its excellent corrosion resistance, durability, and strength, making it suitable for rigorous applications. However, variations such as Inconel or Hastelloy might be recommended based on specific environmental conditions such as extreme temperatures or chemical exposures. A knowledgeable supplier will advise on the optimal material selection based on your unique needs, adding another layer of expertise to the purchasing process. Ultimately, the decision to invest in high-quality Dutch weave wire cloth is one that promises long-term benefits, including greater efficiency, reduced maintenance costs, and enhanced product quality. By collaborating with a reputable and experienced manufacturer, you ensure that your investment delivers on its promises and positions your operations for success in a competitive landscape. Whether you're in the initial stages of product research or ready to make a purchase, prioritizing these factors will enable a choice that supports operational excellence and business growth.

share

Next:

Latest news

-

Window Magnetic Mosquito Net for Windows Strong Magnets, Easy Install

NewsJun.04,2025

-

Premium SS304 Wire Mesh Supplier ODM, Discount & Wholesale

NewsJun.04,2025

-

16x20x1 Air Filter Premium Dust & Allergen Removal for Your Home

NewsJun.04,2025

-

Attic Window Mosquito Net Fiber Mesh for Sliding Windows

NewsJun.04,2025

-

High-Grade 316L Stainless Steel Wire Mesh Durable & Corrosion-Resistant

NewsJun.04,2025

-

1 Micron Filter Cartridge High-Efficiency Particle Removal

NewsJun.04,2025