Jan . 17, 2025 05:40 Back to list

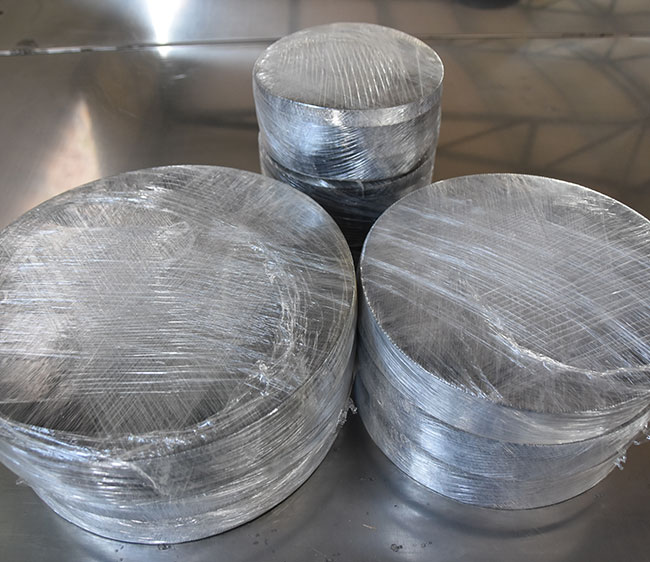

Grain industry filter Woven Mesh

Navigating the intricate world of industrial materials can often be daunting, especially when seeking high-quality components like fine woven mesh. With its diverse applications, from architectural design to industrial processing and environmental engineering, understanding the ins and outs of purchasing fine woven mesh becomes crucial. Leveraging firsthand experience, professional expertise, and industry authority, this guide aims to offer trustworthy insights into acquiring the best fine woven mesh for your needs.

Price is undoubtedly a key factor in any purchasing decision. However, it's imperative to balance cost against quality and longevity. Cheaper meshes might save upfront costs, but higher-quality meshes often offer long-term savings by reducing maintenance costs and extending the lifespan of the material. Engaging with industry experts reveals that investing in higher-grade materials up front can translate into significant future savings, especially in demanding operational environments. Furthermore, sustainability is an increasingly critical factor in today's purchasing decisions. Seek suppliers who not only provide high-quality products but also adhere to environmentally friendly and sustainable manufacturing practices. This adherence indicates a responsible approach to production and ensures that you are making a purchasing decision aligned with current global environmental standards. Whether you are in aerospace, automotive, or any other industry requiring fine woven mesh, the key to a successful purchase lies in thorough research and a clear understanding of your specific application needs. Drawing on collective experience and expertise can lead to informed decisions that ensure the optimal performance of the mesh in its intended application. In conclusion, purchasing fine woven mesh demands careful consideration of material, weave type, supplier credibility, technological advancements, cost, and sustainability. With the insights shared in this guide rooted in actual industry practice and professional expertise, you are well-equipped to navigate the complexities of selecting the right fine woven mesh that aligns with your technical specifications and operational requirements. Through this informed approach, you can confidently invest in fine woven mesh that not only meets but exceeds your expectations in performance and value.

Price is undoubtedly a key factor in any purchasing decision. However, it's imperative to balance cost against quality and longevity. Cheaper meshes might save upfront costs, but higher-quality meshes often offer long-term savings by reducing maintenance costs and extending the lifespan of the material. Engaging with industry experts reveals that investing in higher-grade materials up front can translate into significant future savings, especially in demanding operational environments. Furthermore, sustainability is an increasingly critical factor in today's purchasing decisions. Seek suppliers who not only provide high-quality products but also adhere to environmentally friendly and sustainable manufacturing practices. This adherence indicates a responsible approach to production and ensures that you are making a purchasing decision aligned with current global environmental standards. Whether you are in aerospace, automotive, or any other industry requiring fine woven mesh, the key to a successful purchase lies in thorough research and a clear understanding of your specific application needs. Drawing on collective experience and expertise can lead to informed decisions that ensure the optimal performance of the mesh in its intended application. In conclusion, purchasing fine woven mesh demands careful consideration of material, weave type, supplier credibility, technological advancements, cost, and sustainability. With the insights shared in this guide rooted in actual industry practice and professional expertise, you are well-equipped to navigate the complexities of selecting the right fine woven mesh that aligns with your technical specifications and operational requirements. Through this informed approach, you can confidently invest in fine woven mesh that not only meets but exceeds your expectations in performance and value.

share

Next:

Latest news

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025