321 304 316Plain Dutch Weave Stainless Steel Wire Mesh

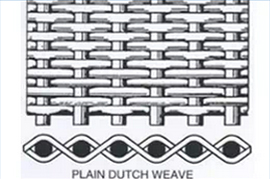

Plain Dutch Weave Mesh is woven by taking shut and warp wires in the different diameters. Shute wire has smaller diameter in microns that is woven with warp wire of bigger diameter. The shute wire is tightly woven to produce high strength mesh while allowing smooth flow.The size of thinner wire is in microns and is woven tightly together offering a tight wire mesh for filtration operations. The bigger wire strengthens the mesh. The Plain Dutch Weave Mesh is used in the filtration and separation of liquid and slurry materials.Plain Dutch Weave Mesh is one of our best products,it is exported to Russia,Ukraine,Italy,France and other countries in the world.

When compared with square, oblong or broad weave meshes, Plain Dutch Weave Mesh offers increased mechanical strength for industrial filtration.Thanks to their closed surface, filtration occurs at the point where warp and weft join. Dutch weave is manufactured in plain weave pattern (1/1), whereby the warp wires are interwoven with a wider pitch than the weft wires. This significantly increases the strength of the mesh in comparison with square meshes.

ANPING GOLDFLOWER WIRE MESH FACTORY is an expert weaver of Dutch Woven Wire Cloth and stainless steel wire cloth. We offer various grades of woven wire mesh and woven wire cloth in stainless steel, brass, copper and other metal materials. In this page, we mainly introduce Plain Dutch Weave Mesh (Professional Standard).Welcome to CONTACT US for more information!

Plain Dutch weave cloth same as plain weaving square mesh, the difference is the diameter of the warp wire is larger than the weft wire.The plain Dutch weave cloth is formed by weaving a limited number of warps wires with the maximum number of weft wires woven tightly together, producing a cloth with no readily visible aperture. the shape and position of the openings aid particle retention and increase filter cake formation.

Plain weave:

Each warp wire and each weft wire passes over and under the next adjacent wire.

Plain dutch weave woven wire cloth has two sizes of wire diameter. The weft wires has thinner wire diameter, which is woven tightly together to provide a tight mesh for filtering. The warp wires has coarser wire diameter, which provides strength to the woven wire cloth.

Specifications Of Plain Dutch Weave Mesh:

321-304-316 Plain Dutch Weave Mesh.

Material: Aisi321, 302, 304, 304L, 316 and 316L stainless steel wire, black wire, Al5Cr23, Ni80Cr20, Ni60Cr15 and etc.

Weave: plain dutch, twilled dutch, reverse, five heddle weave.

Characteristics: acid resisting, alkali resisting, heat resisting and wear resisting.

Application: used for industries of mining, oil, chemical, food, phamaceutical, machine making, scientific research, aviation, etc.

Plain Dutch Weave Wire Mesh Characteristics

-

Warp wire has bigger dia than shute wire

-

Shute wires are possibly bound close to each other

-

High accuracy

-

Nominal or no pressure loss while filtration

-

Supreme filtration surface

-

More stable than square and rectangular wire mesh

Features Of Plain Dutch Weave Mesh

Fine mesh holes give very high filter precision.

High tensile strength and can operate under heavy pressure.

Has a solid structure and a long service life.

High filtering efficiency

Anticut

Dimensional stability

Great dimensional strength

Anticorrosion

Applications Of Plain Dutch Weave Mesh

Plain Dutch weave mesh is strong and stable, easy to clean and with a good flow rate suitable for high-pressure liquid/solid separation.

It is Widely used in Neutral chloride environment,oil refining industry,petrochemical and chemical industry,chemical industry transportation pipeline,oil and gas industry,pulp and paper industry,chemical fertilizer industry,urea industry,phosphate fertilizer industry,seawater environment,energy and environment protection industry,light industry and food industry,food and pharmaceutical industry equipment,high strength structure.

In a Plain Dutch Weave, the diameter of the warp wire is larger than the weft.The mesh is formed by weaving a limited number of warps with the maximum number of weft wires woven tightly together, producing a cloth with no readily visible apertures.This mesh is strong and stable, easy to clean and with a good flow rate suitable for high-pressure liquid/solid separation.

woven wire cloth is mainly used in the absorption, evaporation and filtration process in petroleum, chemical, medicine, metallurgy, machinery, ship and automobiles to delete the mist drop or liquid foam or used as air filter in cars and trucks. And can be made to extruder screens for melt filtration.

Plain Dutch Weave Mesh is good as compared to broad weave mesh, square mesh or oblong mesh in mechanical strength perspective. With the help of two sizes of different wire, it is woven. Smaller wire is generally used for tight woven that helps in providing tight mesh that helps while filtering where larger wires are used for higher strength.The closed surface of the Plain DutchWeave is good which helps infiltration at the joining point of warp and weft. The material used in the Plain Dutch Weave Mesh is stainless steel, phosphor bronzeand Monel metal. Mainly it is used for separation of various liquid, different slurry products and for the purpose of filtration.

Our product maintains the highest quality standards and is ISO 9001:2008 certified. All of our wire mesh products can be supplied meeting ASTM standards. It is stocked in the several specifications to assure quick delivery.

We offer a broad range of Plain Dutch Weave Mesh that is highly recommended for its large surface structure. The product has competency to obtain high flow levels and nominal pressure drop. These are commonly used for filter candles in edible oil refining, large mechanical loads for pre-coat filters, food and pharmaceutical filtration. We deliver the greater quality Plain Dutch Weave Mesh that is highly reckoned in woven wire filter cloths. Welcome to CONTACT US.

| Plain Dutch Weave Mesh | |||

| Mesh/Inch Warp x Weft |

Wire Diameter mm |

Weight kgs/m2 |

Filtering valueμm |

| 7 x 50 | 0.70 x 0.54 | 4.50 | 315 |

| 8 x 60 | 0.55 x 0.45 | 3.64 | 280 |

| 12 x 64 | 0.58 x 0.42 | 3.80 | 180 |

| 12 x 90 | 0.45x 0.30 | 2.60 | 160 |

| 14 x 88 | 0.50 x 0.33 | 2.81 | 150 |

| 14 x 100 | 0.40 x 0.28 | 2.52 | 140 |

| 18 x 100 | 0.40 x 0.28 | 2.61 | 130 |

| 24 x 110 | 0.35 x 0.25 | 2.45 | 115 |

| 25 x 140 | 0.30 x 0.20 | 1.96 | 100 |

| 30 x 150 | 0.23 x 0.18 | 1.61 | 95 |

| 30 x 160 | 0.23 x 0.18 | 1.69 | 90 |

| 40 x 200 | 0.18 x 0.14 | 1.30 | 75 |

| 45 x 220 | 0.18 x 0.125 | 1.22 | 56 |

| 50 x 250 | 0.14 x 0.11 | 1.00 | 60 |

| 50 x 280 | 0.14 x 0.10 | 0.84 | 45 |

| 60 x 300 | 0.14 x 0.09 | 0.80 | 40 |

| 65 x 320 | 0.12 x 0.085 | 0.75 | 36 |

| 70 x 350 | 0.11 x 0.08 | 0.70 | 34 |

| 70 x 400 | 0.11 x 0.07 | 0.68 | 32 |

| 80 x 400 | 0.12 x 0.07 | 0.55 | 35 |

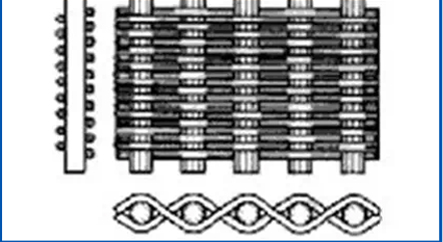

| Twill Dutch Woven Wire Cloth | ||||

| Mesh/Inch Warp x Weft |

Wire Diameter mm |

Weight kgs/m2 |

Filtering valueμm μm |

|

| 20 x 250 | 0.28 x 0.20 | 6.55 | 87 | |

| 30 x 250 | 0.25 x 0.20 | 2.96 | 70 | |

| 80 x 700 | 0.10 x 0.08 | 1.32 | 25 | |

| 80 x 780 | 0.11 x 0.07 | 1.19 | 27 | |

| 100 x 780 | 0.10 x 0.07 | 1.20 | 25 | |

| 100 x 900 | 0.10 x 0.60 | 1.06 | 22 | |

| 100 x 780 | 0.10 x 0.70 | 1.21 | 24 | |

| 120 x 400 | 0.10 x 0.06 | 0.66 | 40 | |

| 120 x 600 | 0.10 x 0.06 | 0.84 | 30 | |

| 120 x 1100 | 0.08 x 0.05 | 0.88 | 18 | |

| 165 x 800 | 0.07 x 0.05 | 0.70 | 15 | |

| 165 x 1200 | 0.07 x 0.04 | 0.68 | 19 | |

| 165 x 1400 | 0.07 x 0.04 | 0.76 | 14 | |

| 200 x 600 | 0.06 x 0.045 | 0.48 | 20 | |

| 200 x 900 | 0.05 x 0.035 | 0.40 | 23 | |

| 200 x 1400 | 0.07 x 0.04 | 0.80 | 10 | |

| 250 x 2000 | 0.04 x 0.027 | 0.46 | 8 | |

| 280 x 2200 | 0.035 x 0.025 | 0.42 | 6.3 | |

| 320 x 2300 | 0.033 x 0.024 | 0.41 | 5 | |

| 325 x 2300 | 0.035 x 0.025 | 0.45 | 5 | |

| 400 x 2800 | 0.025 x 0.020 | 0.36 | 3 | |

| 500 x 3500 | 0.025 x 0.015 | 0.30 | 5 |

|

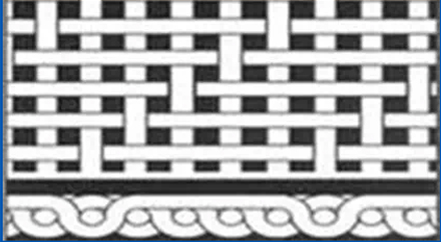

| Reverse Dutch Weave Wire Cloth | ||||

| Mesh/Inch Warp x Weft |

Wire Diameter Warp x Weft mm |

Wire Diameter Warp x Weft inch |

Absolute Filter rating μm |

|

| 63 x 18 | 0.40 x 0.60 | 0.0157 x 0.0236 | 220 | |

| 107 x 20 | 0.24 x 0.60 | 0.0094 x 0.0236 | 210 | |

| 130 x 35 | 0.20 x 0.40 | 0.0079 x 0.0157 | 80 | |

| 132 x 16 | 0.24 x 0.60 | 0.0094 x 0.0236 | 200 | |

| 132 x 32 | 0.20 x 0.40 | 0.0079 x 0.0157 | 105 | |

| 140 x 40 | 0.19 x 0.38 | 0.0075 x 0.015 | 100 | |

| 170 x 40 | 0.20 x 0.45 | 0.0079 x 0.0177 | 130 | |

| 180 x 120 | 0.088 x 0.10 | 0.0035 x 0.004 | 75 | |

| 200 x 120 | 0.08x 0.10 | 0.0031 x 0.004 | 70 | |

| 175 x 40 | 0.15 x 0.38 | 0.0079 x 0.0157 | 70 | |

| 175 x 50 | 0.15 x 0.30 | 0.0059 x 0.012 | 60 | |

| 290 x 75 | 0.09 x 0.20 | 0.0035 x 0.0079 | 55 | |

| 600 x 100 | 0.04x 0.14 | 0.0157 x 0.0055 | 25 | |

| 615 x 130 | 0.04 x 0.13 | 0.0157 x 0.0051 | 22 | |

| 615 x 102 | 0.04x 0.16 | 0.0157 x 0.0063 | 42 | |

| 625 x 133 | 0.04 x 0.13 | 0.0157 x 0.0051 | 17 | |

| 720 x 150 | 0.036 x 0.10 | 0.0014 x 0.0039 | 17 | |

| 850 x 155 | 0.03 x 0.10 | 0.0012 x 0.004 | 10 | |

| Five-heddle Dutch Weave Wire Cloth | |||||

| Mesh/Inch Warp x Weft |

Wire Diameter mm |

Aperture(mm)Warp x Weft | Open Area | Weightkgs/m2 | |

| 108 x 59 | 0.160 | 0.075 x 0.271 | 20 | 1.07 | |

| 110 x 60 | 0.160 | 0.071 x 0.263 | 19 | 1.09 | |

| 38 x 38 | 0.150 | 0.518 x 0.518 | 60 | 0.43 | |

-

Plain dutch weave

-

Twilled dutch weave

-

Reverse dutch waeve 1

-

Reverse dutch weave 2

-

Five-heddle weave

-

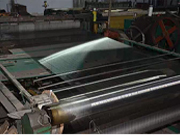

Material Production

-

Diameter Inspect

-

Tension Test

-

Material Check

-

Material Check

-

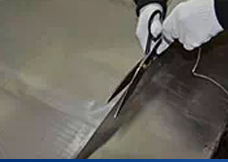

Trimming Edge

-

Length and Width Inspect

-

Hole Size Test

-

Mesh Inspect

-

Weaving

-

Intension Test

-

Diameter Inspect

-

Thickness Inspect

-

Role size Inspect

-

Mesh Test

-

Length and Width Check

-

Trimming Edge

-

Mesh Inspect

With the most perfect way to protect your cargo security

-

1

Cardboard Tube

-

2

Thick Paper Board

-

3

Thick Plastic Cloth

-

4

Perfect Wooden Case

-

5

Thick Plastic Bubble Film

-

6

Excellent Cover

-

7

Steel Strap Fix

-

8

Package Check

-

9

Container Transport