Jun . 19, 2024 03:19 Back to list

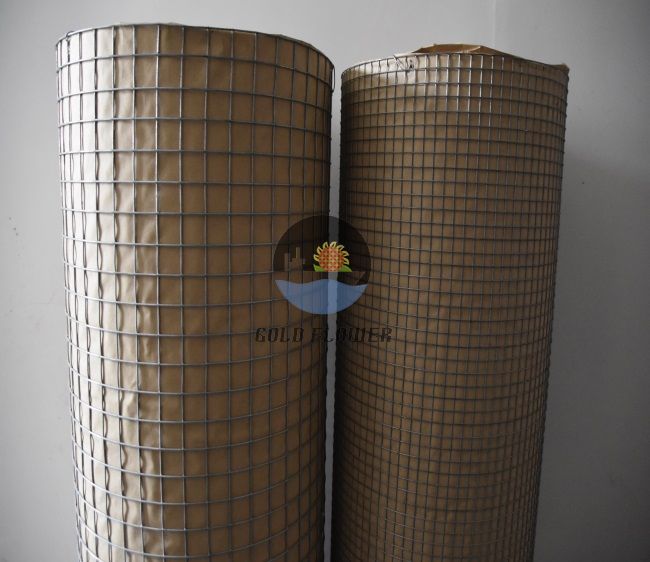

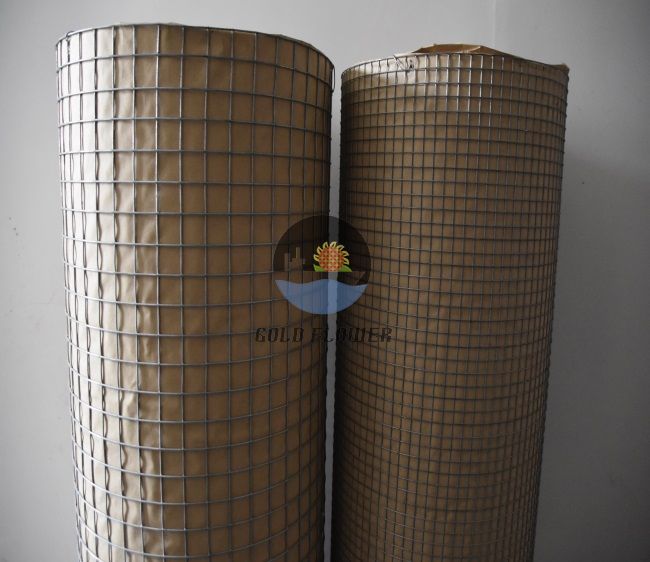

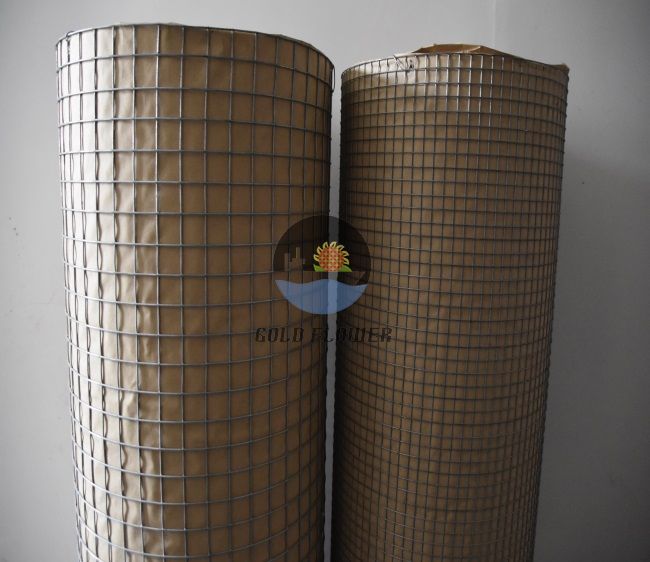

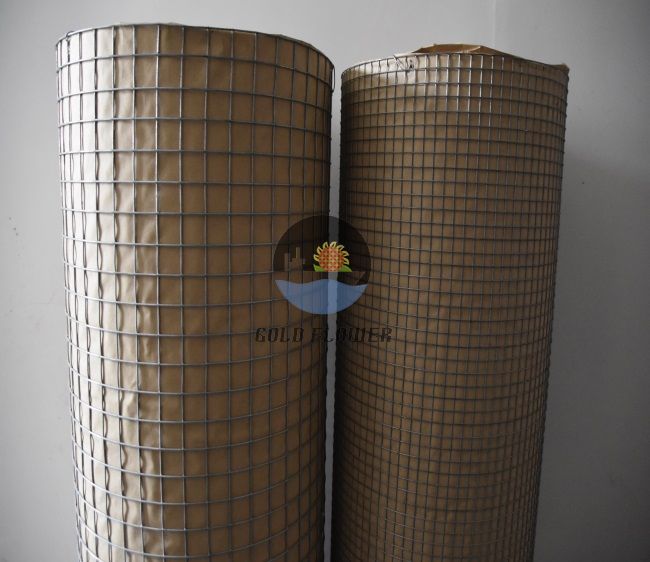

OEM customized wire mesh screens

Understanding the Significance of OEM Wire Cloth Screens in Industrial Applications

OEM (Original Equipment Manufacturer) wire cloth screens play a pivotal role in a wide range of industrial processes, serving as a critical component in filtration, separation, and sizing applications. These specialized meshes are meticulously designed to meet the precise requirements of various industries, from mining and aggregate processing to chemical and food production.

Wire cloth screens, also known as wire mesh or sieve bend, are essentially woven fabrics made from metal wires. They are engineered with a specific pattern of openings, which determine their filtering capabilities. The 'OEM' prefix indicates that these screens are tailor-made to the exact specifications of the equipment they will be integrated into, ensuring optimal performance and longevity.

The manufacturing process of OEM wire cloth screens involves careful consideration of factors such as wire diameter, weave pattern, material type, and aperture size. This is crucial because each of these elements impacts the screen's efficiency in tasks like sieving, straining, or conveying. For instance, a finer wire diameter can provide better filtration, while a specific weave pattern might enhance durability or allow for more efficient particle separation.

In the mining and aggregate industry, OEM wire cloth screens are instrumental in sorting and grading materials. They help separate rocks, sand, and gravel by size, ensuring the consistency and quality of the final product. In chemical processing, these screens are used to filter out impurities, maintaining the purity of the substances being produced In chemical processing, these screens are used to filter out impurities, maintaining the purity of the substances being produced In chemical processing, these screens are used to filter out impurities, maintaining the purity of the substances being produced In chemical processing, these screens are used to filter out impurities, maintaining the purity of the substances being produced

In chemical processing, these screens are used to filter out impurities, maintaining the purity of the substances being produced In chemical processing, these screens are used to filter out impurities, maintaining the purity of the substances being produced oem wire cloth screens.

Food processing industries also heavily rely on OEM wire cloth screens. They are employed in the sifting of flour, sugar, and other food ingredients, as well as in the filtration of oils and juices. The custom design ensures that the screens meet strict hygiene standards and can withstand the rigors of continuous use in a food-safe environment.

The versatility of OEM wire cloth screens lies in their ability to be customized for diverse applications. They can be manufactured in various shapes, sizes, and materials, including stainless steel, brass, copper, and even exotic alloys for high-temperature or corrosive environments. The durability and resilience of these screens make them a cost-effective solution in the long run, despite their initial investment.

In conclusion, OEM wire cloth screens are more than just a simple mesh; they are precision-engineered tools that facilitate efficient and accurate industrial operations. Their importance cannot be overstated, as they contribute significantly to productivity, quality control, and overall process efficiency across multiple sectors. As technology advances, it is expected that these screens will continue to evolve, offering even more specialized solutions to meet the ever-changing demands of modern industries.

oem wire cloth screens.

Food processing industries also heavily rely on OEM wire cloth screens. They are employed in the sifting of flour, sugar, and other food ingredients, as well as in the filtration of oils and juices. The custom design ensures that the screens meet strict hygiene standards and can withstand the rigors of continuous use in a food-safe environment.

The versatility of OEM wire cloth screens lies in their ability to be customized for diverse applications. They can be manufactured in various shapes, sizes, and materials, including stainless steel, brass, copper, and even exotic alloys for high-temperature or corrosive environments. The durability and resilience of these screens make them a cost-effective solution in the long run, despite their initial investment.

In conclusion, OEM wire cloth screens are more than just a simple mesh; they are precision-engineered tools that facilitate efficient and accurate industrial operations. Their importance cannot be overstated, as they contribute significantly to productivity, quality control, and overall process efficiency across multiple sectors. As technology advances, it is expected that these screens will continue to evolve, offering even more specialized solutions to meet the ever-changing demands of modern industries.

In chemical processing, these screens are used to filter out impurities, maintaining the purity of the substances being produced In chemical processing, these screens are used to filter out impurities, maintaining the purity of the substances being produced

In chemical processing, these screens are used to filter out impurities, maintaining the purity of the substances being produced In chemical processing, these screens are used to filter out impurities, maintaining the purity of the substances being produced oem wire cloth screens.

Food processing industries also heavily rely on OEM wire cloth screens. They are employed in the sifting of flour, sugar, and other food ingredients, as well as in the filtration of oils and juices. The custom design ensures that the screens meet strict hygiene standards and can withstand the rigors of continuous use in a food-safe environment.

The versatility of OEM wire cloth screens lies in their ability to be customized for diverse applications. They can be manufactured in various shapes, sizes, and materials, including stainless steel, brass, copper, and even exotic alloys for high-temperature or corrosive environments. The durability and resilience of these screens make them a cost-effective solution in the long run, despite their initial investment.

In conclusion, OEM wire cloth screens are more than just a simple mesh; they are precision-engineered tools that facilitate efficient and accurate industrial operations. Their importance cannot be overstated, as they contribute significantly to productivity, quality control, and overall process efficiency across multiple sectors. As technology advances, it is expected that these screens will continue to evolve, offering even more specialized solutions to meet the ever-changing demands of modern industries.

oem wire cloth screens.

Food processing industries also heavily rely on OEM wire cloth screens. They are employed in the sifting of flour, sugar, and other food ingredients, as well as in the filtration of oils and juices. The custom design ensures that the screens meet strict hygiene standards and can withstand the rigors of continuous use in a food-safe environment.

The versatility of OEM wire cloth screens lies in their ability to be customized for diverse applications. They can be manufactured in various shapes, sizes, and materials, including stainless steel, brass, copper, and even exotic alloys for high-temperature or corrosive environments. The durability and resilience of these screens make them a cost-effective solution in the long run, despite their initial investment.

In conclusion, OEM wire cloth screens are more than just a simple mesh; they are precision-engineered tools that facilitate efficient and accurate industrial operations. Their importance cannot be overstated, as they contribute significantly to productivity, quality control, and overall process efficiency across multiple sectors. As technology advances, it is expected that these screens will continue to evolve, offering even more specialized solutions to meet the ever-changing demands of modern industries. share

Latest news

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025