feb . 17, 2025 20:29 Back to list

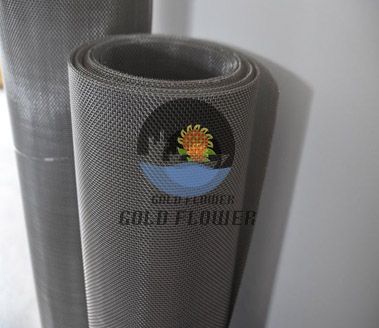

ce certification fine steel mesh screen

Searching for premium-quality fine mesh wire screens can be daunting due to the myriad options available. However, selecting the right wire screen is crucial for a myriad of applications, from industrial use to personal DIY projects. With extensive experience in the field, I offer an authoritative guide to ensure you make an informed purchase, guided by expertise and trustworthiness.

Incorporating user experience is also beneficial when making your choice. Consider reaching out to industry forums or product review sites to gather insights from those who have used similar products in comparable applications. Practical insights into installation difficulties, maintenance requirements, and long-term performance can be invaluable. The ideal wire screen not only meets the technical specifications but consistently performs over time, maintaining its integrity and effectiveness. Manufacturers continually innovate to offer fine mesh wire screens tailored for specific uses. Customization options allow for manufacturing screens that match exact size requirements or incorporating advanced coatings that enhance durability or functionality. If your application has unique demands, engaging directly with manufacturers for a tailored solution might prove advantageous. Lastly, investment in a fine mesh wire screen should be viewed as a strategic decision that influences productivity, safety, and efficacy within your application. While cost is a consideration, durability, performance, and the ability to meet the operational demands should be the primary drivers. Opt for quality and trusted expertise, and count on specialized providers who stand by their products with warranties and customer support. In conclusion, buying the right fine mesh wire screen involves a balance of understanding material properties, mesh specifications, environmental considerations, and supplier reliability. With an approach grounded in experience, expertise, and credibility, you can ensure your purchase not only serves its intended purpose but also stands the test of time.

Incorporating user experience is also beneficial when making your choice. Consider reaching out to industry forums or product review sites to gather insights from those who have used similar products in comparable applications. Practical insights into installation difficulties, maintenance requirements, and long-term performance can be invaluable. The ideal wire screen not only meets the technical specifications but consistently performs over time, maintaining its integrity and effectiveness. Manufacturers continually innovate to offer fine mesh wire screens tailored for specific uses. Customization options allow for manufacturing screens that match exact size requirements or incorporating advanced coatings that enhance durability or functionality. If your application has unique demands, engaging directly with manufacturers for a tailored solution might prove advantageous. Lastly, investment in a fine mesh wire screen should be viewed as a strategic decision that influences productivity, safety, and efficacy within your application. While cost is a consideration, durability, performance, and the ability to meet the operational demands should be the primary drivers. Opt for quality and trusted expertise, and count on specialized providers who stand by their products with warranties and customer support. In conclusion, buying the right fine mesh wire screen involves a balance of understanding material properties, mesh specifications, environmental considerations, and supplier reliability. With an approach grounded in experience, expertise, and credibility, you can ensure your purchase not only serves its intended purpose but also stands the test of time.

share

Next:

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025