aug . 04, 2025 02:00 Back to list

CE Certified 250 Micron Stainless Steel Mesh Filter

The demand for CE certification 250 micron stainless steel mesh and related products is accelerating, driven by advancements in precision manufacturing, enhanced safety standards, and the growth of applications across diverse sectors. This article delves deep into the technology, manufacturing process, applications, performance comparisons, and real project experience related to CE-certified wire mesh solutions including ss 316 mesh, screen printing mesh, square mesh wire fencing, woven fabric, pool fencing, mesh boxes, fine steel mesh screens, heavy-duty wire mesh, and metal fine mesh. Through data analysis and authoritative standards, we provide an actionable reference for engineers, procurement managers, and industry decision-makers.

1. Industry Outlook: The Rising Importance of CE Certification in Stainless Steel Wire Mesh

According to a 2023 Grand View Research report, the global stainless steel wire mesh market is forecast to exceed USD 10 billion by 2027, with double-digit CAGR in critical segments like filtration, F&B, petrochemicals, and industrial safety. In Europe, CE certification is no longer optional; it is a regulatory mandate affecting procurement and market access for stainless steel mesh components, ensuring product compliance with directives on mechanical strength, corrosion resistance and human/environmental safety.

Key Drivers:

- Machine safety & process quality in automation

- Stringent EU/UK/AU building product legislation

- Precision filtration and separation standards

- Sustained demand for stainless steel woven, welded, and perforated mesh in critical infrastructures

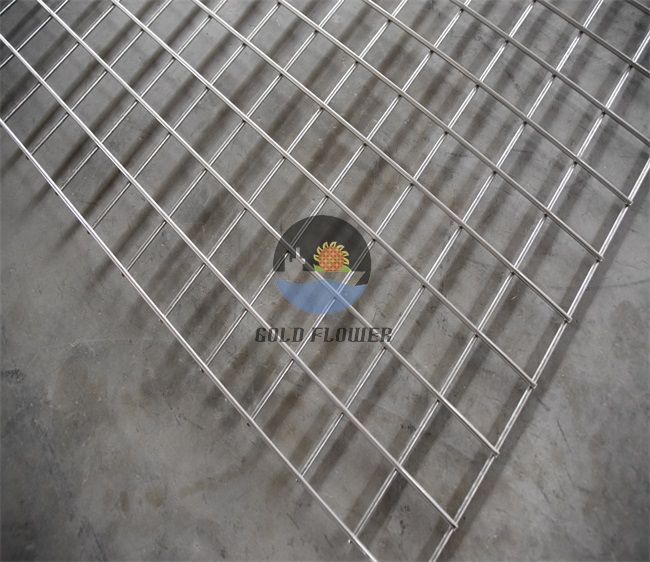

2. Focus Product: 316 Stainless Steel Welded Wire Mesh Panel Technical Datasheet

| Parameter | Value | Standard/Reference |

|---|---|---|

| Material Grade | 316 (EN 1.4401), 316L (EN 1.4404) | ISO 9445, ASTM A580, EN 10088 |

| Wire Diameter | 0.15 mm – 0.25 mm | Typical Tolerance: ±0.01 mm |

| Aperture Size | 250 μm (0.25 mm) | ISO 9044 |

| Mesh Count | 60–110 mesh per inch | ISO 4783-1, ASTM E2016 |

| CE Compliance | EN 10204 3.1/3.2, Module B+D | EU Regulation 305/2011 (CPR), EN 13501 |

| Corrosion Resistance | Excellent (pitting resistance >0.45 PREN) | ASTM G48, EN ISO 9227 Salt Spray Test |

| Surface Finish | Bright/Matte/Polished | EN 10088-2 |

| Typical Sheet Size | 1000 x 2000 mm / Custom Cut | EN 10278 |

| Welding Method | Semi/Automatic Resistance Welding | ISO 4063 (Process 23/25, Spot/Projection) |

3. Manufacturing Process Flow: From Raw Steel to CE Certified 250-Micron Mesh

- Material Selection: High purity SS 316/316L wire rod chosen. (Ensures superb corrosion and pitting resistance)

- →

- Wire Drawing: Multi-stage cold drawing refines wire to 0.15–0.25 mm. Strict down-gauging for mesh accuracy (ISO 10582 Compliance)

- →

- Mesh Weaving or Welding: Automated CNC resistance welding forms mesh grid structure (CE certified per EN 10223 / ISO 9044)

- →

- Surface Finishing: Electro-polishing or chemical passivation (Brightens mesh, removes scale, increases passivity)

- →

- Quality Inspection: Laser aperture checks, tensile/bending tests, salt spray panels for EN/ASTM standard compliance

— All products supplied with CE Declaration, Factory Production Control (FPC) & EN 10204 3.1 mill test certificates - →

- Cut-to-Size & Packaging: Sheet, roll or custom die cut supplied in anti-corrosive film, ready for global shipment.

4. Technical Advantages & Industry Standards

- Material Excellence: Type 316 ensures enduring mechanical and anti-corrosive properties due to elevated Mo & Ni content (per EN 10088, ASTM A240).

- Manufacturing Precision: Modern CNC mesh weaving tolerances ≤ ±7μm for 250μm mesh; laser-cut edges ensure uniformity.

- Surface Quality: Passivated (ASTM A967) finish for exceptional rust resistance in marine and chemical environments; roughness Ra < 0.4 μm.

- CE & ISO Compliance: Fully compliant with EU Construction Products Regulation (EU 305/2011), ISO 9001:2015, ISO 9227 (Salt Spray), EN 10223 Safety Fencing standard, and FDA/REACH directives where chemical compatibility is required.

- Mechanical Strength: Tensile: ≥1240 MPa; Elongation: ≥35% (per EN 10002-1), Flexural and impact tested for pool/screen fencing per AS 1926, EN 13501.

- Longevity: Service life 20~30 years under typical petrochemical, wastewater, or urban conditions, as per accelerated lab/field corrosion data.

5. Product Lineup & Manufacturers Comparison Table

| Product | Wire Diameter (mm) | Aperture (μm) | Mesh Type | CE/ISO Cert | Durability | Typical Application | Manufacturer |

|---|---|---|---|---|---|---|---|

| 316 Stainless Steel Welded Wire Mesh Panel | 0.25 | 250 | Welded/Square | CE, ISO 9001 | 25+ yrs | Filtration, Pool Fencing, Safety Screens | Wiremesh BST |

| SS316 Square Mesh Fencing | 0.5 | 500 | Woven/Square | CE, EN 10223 | 22 yrs | Perimeter Security, Parks | Hebei Anping |

| Fine Steel Mesh Screen (CE) | 0.18 | 150 | Woven/Fine | CE, ISO/ASTM | 18 yrs | Electronics, Inkjet, F&B Sieving | GKD AG |

| Heavy Duty Wire Mesh (316) | 1.2 | 1200 | Welded/Rect | CE, ISO 1793 | 30 yrs | Industry Platforms, Grilles, Barriers | Boegger Industrial |

| Stainless Steel Woven Fabric | 0.22 | 180 | Woven | CE, ISO 4783 | 21 yrs | Screen Printing, Laboratory | TWP Inc. |

6. Customized Solutions for Industrial Needs

No two applications are the same. Whether implementing ce certification 250 micron stainless steel mesh for high-purity filtration, architectural security, or specialized screen printing, bespoke engineering is key:

- Thickness/Aperture Matching: Custom mesh counts and wire gauge to fit application (60-110 mesh/inch, 0.15–0.3mm wire: opt. for ink, ultra-fine separation, hazardous gas filtration).

- Edge/Welding Techniques: Welded, crimped, or unframed; laser or mechanical cut per drawing; CNC spot welding for mesh boxes/screen frames.

- Surface Finish Enhancement: Electro-polished, pickled or passivated surfaces for maximum hygiene (pharmaceutical, food use), or black-oxide for anti-glare security fencing.

- Form Factor: Sheets, rolls, discs, multi-layer composite mesh (for multi-stage filtration, automotive DPF).

- Certification Packaging: Full CE/FDA/ISO dossiers and mill test certificates traceable by lot/batch, to ensure legal and technical compliance globally.

7. Application Scenarios: Engineering Case Studies & Field Results

Challenge: Corrosive vapors and hot caustics destroy conventional mild steel mesh in <6 months.

Solution: CE certification 250 micron stainless steel mesh panels installed as catalyst support grid; maintained mechanical integrity after 28 months, zero shutdowns for mesh replacement.

Reference: Operator report, Yanbu Refinery Turnaround 2022.

Challenge: Ink bleed & mesh deformation with non-CE mesh.

Solution: Adoption of ce certification stainless steel wire mesh for screen printing: tolerance ≤±7μm, ink spread below 1%. Enhanced yield, reduced cleaning downtime by 37% (internal QA data, 2023).

Challenge: Stringent compliance with AS1926, corrosion from chlorine and salt.

Solution: ce certification wire mesh pool fencing installed; surface passivation enabled 15-year+ rust resistance, zero warranty repairs.

Challenge: Need for EN 13501 impact rating on machinery guards.

Solution: ce certification heavy duty wire mesh exceeded test impact energy (IE 20J) by 30%; certified for all listed equipment.

CE certified stainless steel woven fabric utilized for HEPA pre-screen mesh, outperforming glass fiber (cleanroom ISO 6 compliance, customer testimonial).

8. Frequently Asked Technical Questions: CE Certified Wire Mesh Systems

9. Delivery Schedule, Warranty, and After-Sales Support

- Delivery Lead Time: Typically 14–21 days (Europe/NA), expedited 7 days for standard items; custom sheet/roll sizes: +7 days.

- Global Logistics: Secure export grade packaging, shipment with full CE/ISO certification, tracked via global logistics partners (Maersk, DHL, etc).

- Warranty: 5-year anti-corrosion and structural warranty for all ce certification 250 micron stainless steel mesh and welded mesh panels; batch traceability for claim resolution.

- 24/7 Support: Multilingual tech team (EN/DE/FR) for drawings, spec clarifications, or troubleshooting across time zones (E-mail/WhatsApp/WeChat).

- Documentation: CE Declaration, ISO/EN certificates, material data sheets, test reports, installation guides provided with each order.

10. Conclusion: Why Trust CE Certification 250 Micron Stainless Steel Mesh for Next-Gen Projects?

In summary, ce certification 250 micron stainless steel mesh and its extended range (fine mesh screen, heavy duty welded panels, stainless mesh boxes) offer unrivaled performance and safety assurance for today's demanding global projects—delivering high corrosion resistance, mechanical strength and certified compliance with every batch. As engineering requirements rise and environmental safety regulations tighten, the smart choice is to specify CE-certified, ISO-compliant stainless steel mesh from a traceable, tested, and responsive supplier.

Industry-leading brands and hundreds of successful installations endorse this next-generation wire mesh platform as the gold standard in filtration, screening, fencing, and specialty engineering domains.

[1] Grand View Research. Welded Wire Mesh Market Analysis. Link

[2] Stainless Steel World Magazine. EN/ISO/ASTM Mesh Standards Update. Link

[3] Wire Mesh Forum: User Experiences with CE Certification, Real-Life FAQ Link

[4] European Commission Construction Product Regulation (EU 305/2011): Link

share

This is the last article

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025