feb . 15, 2025 02:40 Back to list

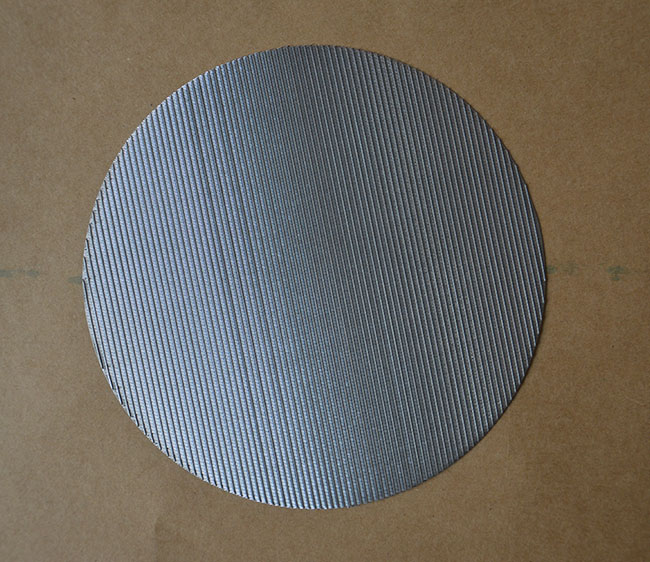

ce certification square mesh wire fencing

When considering the purchase of a wire mesh fencing machine, a nuanced understanding of the product's intricacies and capabilities is pivotal. Wire mesh fencing machines are essential assets for businesses aiming to produce durable and reliable fencing solutions efficiently. These machines have revolutionized the production of wire mesh, offering enhanced precision, speed, and flexibility. Here, we delve into the key expertise and authoritative insights you need to acquire a wire mesh fencing machine that best suits your business needs.

Cost is, undeniably, a defining factor but should be evaluated in conjunction with long-term value. While the initial investment in a high-quality wire mesh fencing machine may be substantial, consider the long-term operational costs and benefits. Cost-effective machines might come with hidden expenses such as frequent repairs, higher energy consumption, or lower efficiency, which could affect your business's profitability. Conduct a cost-benefit analysis considering aspects such as energy efficiency, lifecycle expenses, and potential return on investment. Before finalizing a purchase, seek testimonials and reviews from existing users. Experiences from other businesses can offer invaluable insights into the machine's performance and the quality of post-purchase support from the manufacturer. Engage with industry experts or visit trade shows and exhibitions to see machines in operation and gather first-hand experience. Finally, ensure compliance with industry standards and regulations. Depending on your geographical location, specific standards related to safety, environmental impact, and technical specifications must be adhered to. Purchasing a machine that complies with these standards not only ensures safety but also enhances the credibility and trustworthiness of your business operations. In conclusion, acquiring a wire mesh fencing machine is a significant investment that requires thorough research and due diligence. By focusing on automation, capacity, durability, operational ease, cost-effectiveness, and compliance, businesses can make informed purchasing decisions. These considerations ensure that the machine not only fits current demands but also aligns with future growth strategies, enhancing both efficiency and market competitiveness.

Cost is, undeniably, a defining factor but should be evaluated in conjunction with long-term value. While the initial investment in a high-quality wire mesh fencing machine may be substantial, consider the long-term operational costs and benefits. Cost-effective machines might come with hidden expenses such as frequent repairs, higher energy consumption, or lower efficiency, which could affect your business's profitability. Conduct a cost-benefit analysis considering aspects such as energy efficiency, lifecycle expenses, and potential return on investment. Before finalizing a purchase, seek testimonials and reviews from existing users. Experiences from other businesses can offer invaluable insights into the machine's performance and the quality of post-purchase support from the manufacturer. Engage with industry experts or visit trade shows and exhibitions to see machines in operation and gather first-hand experience. Finally, ensure compliance with industry standards and regulations. Depending on your geographical location, specific standards related to safety, environmental impact, and technical specifications must be adhered to. Purchasing a machine that complies with these standards not only ensures safety but also enhances the credibility and trustworthiness of your business operations. In conclusion, acquiring a wire mesh fencing machine is a significant investment that requires thorough research and due diligence. By focusing on automation, capacity, durability, operational ease, cost-effectiveness, and compliance, businesses can make informed purchasing decisions. These considerations ensure that the machine not only fits current demands but also aligns with future growth strategies, enhancing both efficiency and market competitiveness.

share

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025