des . 29, 2024 23:01 Back to list

Exploring the Impact of ODM Steel Net on Industry Trends and Innovations

Exploring the Rise of ODM Steel Net A Game-Changer in the Steel Industry

In recent years, the steel industry has undergone substantial transformations, driven by technological advancements, increased demand for sustainability, and the need for improved efficiency. Among the innovations that have emerged, ODM Steel Net has gained significant attention as a revolutionary solution poised to redefine the landscape of steel manufacturing and distribution.

ODM, which stands for Original Design Manufacturer, combines the principles of original design and manufacturing capabilities to create high-quality steel products and solutions. At the heart of this model is a commitment to innovation, customization, and agility in response to market dynamics. The technology underlying ODM Steel Net leverages digital tools, data analytics, and advanced manufacturing techniques to optimize production processes while minimizing waste and reducing environmental impact.

One of the most compelling aspects of ODM Steel Net is its focus on sustainability. As the world grapples with climate change and resource depletion, industries are under increasing pressure to adopt greener practices. ODM Steel Net utilizes strategies such as recycled materials, energy-efficient production methods, and eco-friendly coatings. This sustainable approach not only reduces the carbon footprint but also meets the growing demand for environmentally responsible steel products from consumers and industries alike.

Another significant benefit of ODM Steel Net is its ability to foster collaboration and transparency across the supply chain. By utilizing digital platforms, manufacturers, suppliers, and customers can share real-time data, streamline communications, and enhance decision-making processes. This collaborative environment enables stakeholders to respond more swiftly to market fluctuations and consumer demands, resulting in improved product availability and reduced lead times.

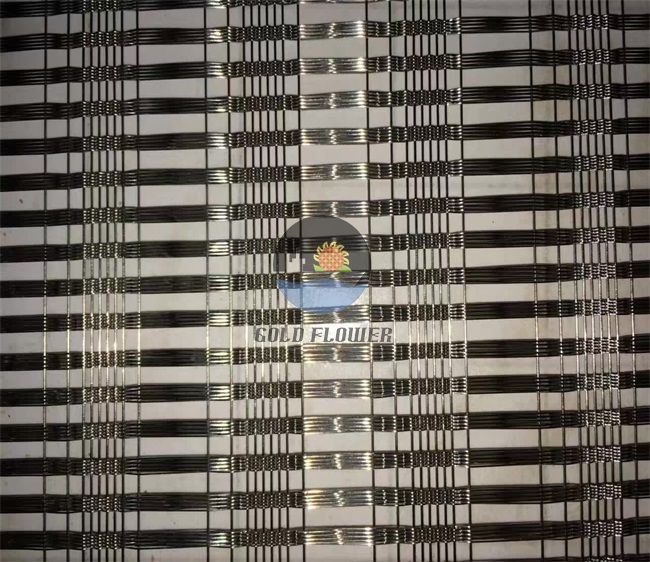

odm steel net

The customization aspect of ODM Steel Net is particularly noteworthy. Traditional steel manufacturing often leads to mass-produced, one-size-fits-all solutions that can fall short of meeting specific client needs. In contrast, ODM Steel Net allows for tailored solutions that cater to the unique requirements of various industries, such as construction, automotive, and energy. Whether it involves altering specifications, adjusting dimensions, or developing specialized alloys, the ability to offer personalized products significantly enhances customer satisfaction and loyalty.

Furthermore, the integration of IoT (Internet of Things) within ODM Steel Net enables real-time monitoring and predictive maintenance of machinery and equipment. This feature minimizes downtime and maximizes productivity, contributing to overall operational efficiency. By utilizing data analytics, manufacturers can identify potential issues before they escalate, leading to cost savings and a more streamlined production process.

As ODM Steel Net continues to gain traction, it is essential to recognize its potential impacts on the future of the steel industry. The shift towards a more digitized, sustainable, and customer-centric approach signifies a departure from traditional methods that may no longer be feasible in a rapidly changing global economy.

Ultimately, ODM Steel Net represents a convergence of technology, sustainability, and adaptability that is set to drive the steel industry forward. Companies that embrace this innovative model will not only enhance their competitive advantage but also contribute to a more sustainable future. As we move ahead, it will be fascinating to witness how this paradigm shift shapes the landscape of the steel industry in the years to come. Embracing the change that ODM Steel Net brings is not just an opportunity; it is a necessity for thriving in an increasingly complex and demanding market.

share

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.09,2025

-

Decorative Brass Mesh: Elevate Interiors with Timeless Elegance

NewsAug.08,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.07,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Fine & Durable

NewsAug.06,2025

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025