jan . 09, 2025 13:59 Back to list

wire mesh

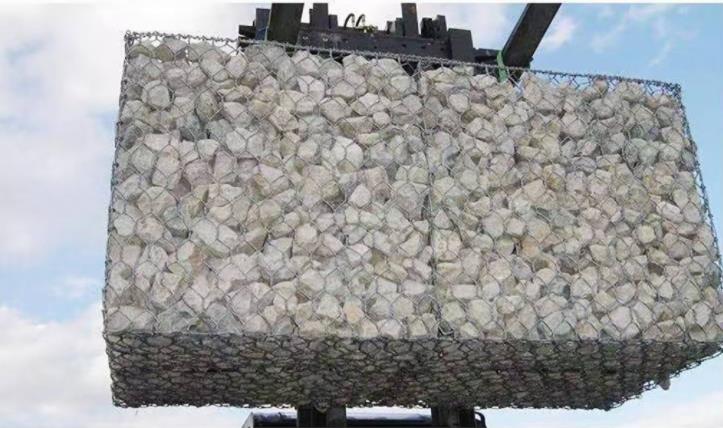

Wire mesh, an exceptionally versatile material, has become an integral component in a multitude of industries ranging from construction to agriculture. Its adaptability is defined by its intricate network of intersecting metal wires, creating a grid-like structure that can be customized in an array of configurations, sizes, and materials depending on the application.

The expertise involved in crafting wire mesh products can’t be overstated. It requires a deep understanding of metallurgy and engineering principles to produce mesh that meets specific needs. Manufacturers must consider factors such as tensile strength, flexibility, and corrosion resistance to ensure that the wire mesh delivers on quality and performance expectations. Trustworthiness in wire mesh products is paramount, particularly in industries where failures could lead to significant economic or safety repercussions. Reputable vendors often provide certifications and testing results that verify the quality and compliance of their mesh products with industry standards. This transparency builds confidence among consumers and partners, reinforcing the reliability of wire mesh as a critical component in diverse applications. The authority of companies specializing in wire mesh is often established through years of experience and a history of innovation. Understanding client needs and delivering tailored solutions fosters long-term partnerships and positions these companies as leaders in their field. Continual investment in technology and training ensures that they remain at the forefront of advancements, setting benchmarks and contributing to industry best practices. With its proven track record across various sectors, wire mesh continues to evolve, offering new possibilities and addressing emerging challenges. Its ability to combine strength, flexibility, and functionality makes it indispensable in a world that increasingly values efficiency and sustainability. As industries move forward, the reliance on wire mesh is expected to grow, underscoring its enduring relevance in an ever-changing landscape.

The expertise involved in crafting wire mesh products can’t be overstated. It requires a deep understanding of metallurgy and engineering principles to produce mesh that meets specific needs. Manufacturers must consider factors such as tensile strength, flexibility, and corrosion resistance to ensure that the wire mesh delivers on quality and performance expectations. Trustworthiness in wire mesh products is paramount, particularly in industries where failures could lead to significant economic or safety repercussions. Reputable vendors often provide certifications and testing results that verify the quality and compliance of their mesh products with industry standards. This transparency builds confidence among consumers and partners, reinforcing the reliability of wire mesh as a critical component in diverse applications. The authority of companies specializing in wire mesh is often established through years of experience and a history of innovation. Understanding client needs and delivering tailored solutions fosters long-term partnerships and positions these companies as leaders in their field. Continual investment in technology and training ensures that they remain at the forefront of advancements, setting benchmarks and contributing to industry best practices. With its proven track record across various sectors, wire mesh continues to evolve, offering new possibilities and addressing emerging challenges. Its ability to combine strength, flexibility, and functionality makes it indispensable in a world that increasingly values efficiency and sustainability. As industries move forward, the reliance on wire mesh is expected to grow, underscoring its enduring relevance in an ever-changing landscape.

share

Next:

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.09,2025

-

Decorative Brass Mesh: Elevate Interiors with Timeless Elegance

NewsAug.08,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.07,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Fine & Durable

NewsAug.06,2025

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025