sie . 08, 2025 01:20 Back to list

Decorative Brass Mesh: Elevate Interiors with Timeless Elegance

In an era where design meets functionality, the demand for materials that offer both aesthetic appeal and robust performance is paramount. Among these, brass decorative mesh stands out as a material of choice for architects, interior designers, and product developers alike. Its unique combination of classic elegance and modern versatility makes it an indispensable element in contemporary and traditional applications. This comprehensive guide delves into the world of brass decorative mesh, exploring its technical intricacies, diverse applications, manufacturing excellence, and why it represents a superior investment for your projects.

1. The Resurgence of Brass in Modern Design

Brass, an alloy primarily of copper and zinc, has captivated humanity for centuries with its golden luster and remarkable durability. From ancient artifacts to Victorian-era decor, brass has consistently symbolized luxury and enduring quality. Today, this noble metal is experiencing a significant resurgence, particularly in architectural and interior design. The warm, inviting tones of brass decorative mesh, ranging from a bright polished gold to a rich, antique patina, offer a versatile palette that complements a myriad of design styles – from minimalist modern to rustic industrial, and opulent classical. Its ability to diffuse light softly, create subtle reflections, and provide a sense of depth makes it an ideal material for crafting unique and inviting spaces.

Beyond its aesthetic virtues, **brass decorative mesh** offers inherent physical advantages. It is naturally resistant to corrosion, provides excellent formability, and possesses antimicrobial properties, making it not just beautiful but also hygienic and long-lasting. This blend of beauty and functionality positions **brass decorative mesh** as a leading choice for sophisticated and sustainable design solutions.

2. Understanding Brass Decorative Mesh: Definition and Types

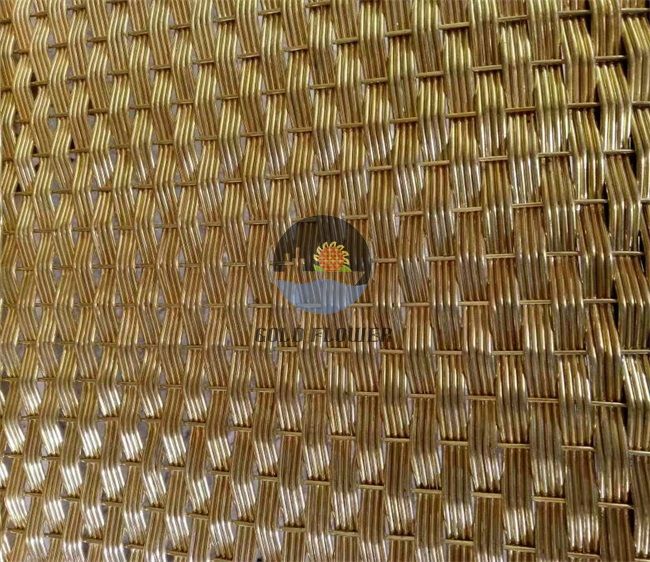

Brass decorative mesh, also known as **decorative brass wire mesh** or **decorative brass mesh screen**, refers to a woven or crimped fabric made from brass wires. Unlike industrial meshes designed for filtration or structural support, decorative mesh prioritizes visual appeal, texture, and light interaction, while still offering durability and semi-privacy. The inherent malleability of brass allows for a wide range of weave patterns and wire gauges, enabling designers to achieve specific aesthetic and functional outcomes.

2.1 Common Brass Alloys for Mesh Production

The choice of brass alloy significantly impacts the mesh's appearance, workability, and corrosion resistance. The most common alloys used for **decorative brass wire mesh** include:

- Cartridge Brass (C26000): Composed of approximately 70% copper and 30% zinc. This alloy is highly ductile, making it excellent for wire drawing and weaving. It offers a bright, golden color when polished and good corrosion resistance. It's often the preferred choice for applications requiring intricate patterns.

- Yellow Brass (C27000): Typically contains 65% copper and 35% zinc. Slightly harder than C26000, it still offers good formability and a distinct yellow hue. It's a cost-effective alternative for many decorative applications.

- Commercial Bronze (C22000): Despite its name, this is a high-copper brass with 90% copper and 10% zinc. It has a richer, reddish-gold color, excellent corrosion resistance, and good cold-working properties. It's often chosen for applications where a warmer tone is desired or for outdoor use.

Understanding these material specifications (often standardized by organizations like ASTM, e.g., ASTM B134 for brass wire) is crucial for ensuring the mesh meets performance and aesthetic expectations for various project environments.

2.2 Weave Patterns and Their Effects

The weaving process dictates the mesh's pattern, texture, open area, and overall visual impact. Key weave types for **decorative brass mesh screen** include:

- Plain Weave: The simplest and most common. Each warp wire (longitudinal) passes alternately over and under each weft wire (transverse). This results in a stable, tight mesh with good open area and a uniform appearance.

- Twill Weave: Each warp wire passes over two weft wires, then under two weft wires, creating a diagonal pattern. This allows for thicker wires and a denser, stronger mesh with a unique textural quality, often appearing more opaque than plain weave.

- Dutch Weave: Characterized by a tighter packing of weft wires than warp wires, creating a mesh with very small, triangular openings. While often used for filtration due to its fine openings, a coarse Dutch weave can be used decoratively for its distinct, almost solid appearance with subtle light play.

- Crimped Weave: Wires are pre-crimped (bent) before weaving, locking them in place. This creates a highly stable, rigid mesh with square or rectangular openings, often with a three-dimensional effect. Crimped mesh is excellent for architectural applications requiring structural integrity and a bold pattern.

The interplay of wire diameter, mesh count (number of openings per linear inch), and weave pattern allows for an infinite array of textures and visual effects, making **brass decorative mesh** incredibly adaptable to specific design visions.

3. Technical Parameters and Specifications: A Data-Driven Approach

Selecting the right **decorative brass wire mesh** requires a precise understanding of its technical parameters. These specifications dictate not only its aesthetic properties but also its performance, durability, and suitability for specific applications. Our **Brass Decorative Mesh** at wiremeshbst.com/brass-decorative-mesh.html is manufactured to rigorous standards, ensuring optimal performance and consistency.

3.1 Key Technical Parameters Explained

- Mesh Count (M/Inch): The number of openings per linear inch, measured from the center of one wire to the center of the next parallel wire. A higher mesh count means smaller openings and a finer, denser mesh.

- Wire Diameter (mm/inch): The thickness of the individual brass wires used in weaving. This impacts the mesh's strength, rigidity, and the visual weight of the pattern.

- Open Area (%): The percentage of the total area that is open space (not covered by wire). This is crucial for applications requiring light transmission, airflow, or transparency. It's calculated based on mesh count and wire diameter.

- Aperture/Opening Size (mm/inch): The clear distance between two adjacent parallel wires. This directly relates to the mesh count and wire diameter.

- Weight (kg/m² or lbs/sq ft): The weight per unit area of the mesh. Important for structural load calculations in architectural installations.

- Tensile Strength (MPa): The maximum stress the brass wire can withstand before breaking. Indicates the mesh's robustness and resistance to stretching. Typical values for brass wire (e.g., C26000 annealed) can range from 310-440 MPa.

- Corrosion Resistance: While brass is inherently corrosion-resistant, the specific alloy and any post-treatment (lacquering) will influence its performance in different environments, such as high humidity or coastal areas.

3.2 Brass Decorative Mesh Product Specifications Table

Below is a typical range of specifications for **decorative brass mesh screen**, representing commonly available and highly versatile configurations. These parameters are crucial for architects and designers in specifying the ideal mesh for their projects.

| Parameter | Typical Range / Value | Unit | Description |

|---|---|---|---|

| Alloy Type | C26000 (70/30 Brass) | N/A | Most common, excellent for decorative uses. Other alloys available on request. |

| Mesh Count | 2 to 200 | M/Inch | Determines density and openness. |

| Wire Diameter | 0.05 to 2.0 | mm | Thickness of individual wires. Impacts strength and visual presence. |

| Open Area | 15% to 85% | % | Percentage of void space; affects light/air transmission. |

| Aperture Size | 0.1 to 12.5 | mm | Size of individual openings. |

| Roll Width | 0.914 to 1.524 (36" to 60") | Meter/Inch | Standard manufacturing widths. Custom widths available. |

| Tensile Strength (C26000 Annealed) | 310 - 440 | MPa | Resistance to breaking under tension. |

| Melting Point | 900 - 940 | °C | Thermal property of the brass alloy. |

| Density | 8.53 | g/cm³ | Weight per unit volume of the brass material. |

| Surface Finish | Mill Finish, Polished, Lacquered, Antique | N/A | Appearance and protective coating options. |

4. The Meticulous Craft: Manufacturing Process of Brass Decorative Mesh

The production of high-quality brass decorative mesh is a sophisticated process that combines traditional weaving techniques with modern precision engineering. Our commitment to excellence at WireMeshBST ensures that every sheet of **decorative brass wire mesh** meets stringent quality standards. The general manufacturing process involves several critical stages:

Raw Material Sourcing & Inspection

The process begins with sourcing high-grade brass wire, typically C26000 or C27000, from reputable suppliers. Each batch undergoes rigorous inspection for chemical composition (using X-ray fluorescence or atomic absorption spectroscopy to ensure precise copper-zinc ratios), wire diameter consistency, and mechanical properties like tensile strength and ductility. Adherence to standards like ASTM B134 for brass wire ensures the foundational quality of the mesh.

Wire Drawing & Annealing

If the raw wire is not already at the desired gauge, it undergoes a wire drawing process. This involves pulling the wire through progressively smaller dies to reduce its diameter to the exact specification required for the mesh. Drawing increases tensile strength but can make the wire brittle. Therefore, an annealing process (heat treatment) is often performed. Annealing softens the brass wire by recrystallizing its grain structure, making it pliable and ductile enough for the weaving process without fracturing.

Weaving (Crimping & Weaving for Crimped Mesh)

This is the core of mesh production. Precision looms are set up according to the specified mesh count, wire diameter, and weave pattern (plain, twill, crimped). Warp wires are threaded onto the loom, and weft wires are interlaced horizontally. For crimped mesh, wires are pre-crimped using specialized machinery to create precise undulations before being woven. This crimping ensures that the wires interlock firmly, creating a highly stable and rigid mesh with excellent dimensional accuracy. The weaving speed and tension are carefully controlled to maintain uniform mesh openings and avoid defects.

Cleaning & Finishing

After weaving, the **decorative brass wire mesh** may undergo a cleaning process to remove any residues from the manufacturing process. Depending on the desired final aesthetic, various finishing treatments are applied:

- Polishing: To achieve a bright, lustrous golden finish.

- Lacquering: A clear protective coat applied to prevent tarnishing and maintain the initial polished appearance, extending its aesthetic life. This is particularly beneficial for applications where maintaining a consistent look over time is critical.

- Antiquing/Patination: Chemical treatments are used to accelerate the natural oxidation process, creating a darker, aged, or distressed look. This is popular for historical restoration or rustic designs.

Quality Control & Inspection

Every roll or sheet of brass decorative mesh undergoes stringent quality control. This includes visual inspection for defects, precise measurement of mesh count, wire diameter, and aperture size using calibrated instruments. Mechanical tests like tensile strength and elongation are performed on wire samples to ensure structural integrity. Adherence to international standards such as ISO 9001 for quality management systems is paramount, guaranteeing product consistency and reliability. This meticulous inspection process ensures that the mesh will perform as expected in its intended application, offering excellent longevity and aesthetic durability, even in demanding environments like high-traffic commercial spaces or moderately humid architectural settings.

5. Unveiling the Potential: Diverse Applications of Brass Decorative Mesh

The versatility and aesthetic appeal of brass decorative mesh have made it a preferred material across a broad spectrum of industries and applications. Its ability to combine visual lightness with material presence allows for innovative design solutions.

5.1 Architectural and Interior Design

This is arguably the largest application area for **decorative brass wire mesh**. It is extensively used for:

- Facades and Cladding: For exterior architectural elements, offering sun shading, ventilation, and a striking visual effect that changes with light conditions. Its corrosion resistance ensures longevity outdoors.

- Space Dividers and Partitions: Creating elegant, semi-transparent barriers in open-plan offices, restaurants, hotels, and residential spaces, allowing for light and air flow while defining areas.

- Ceiling Panels and Wall Coverings: Adding texture, shimmer, and depth to surfaces, enhancing acoustics and creating a luxurious ambiance.

- Balustrade and Railing Infill Panels: Providing safety without obstructing views, while adding a sophisticated design element.

- Elevator Cabs and Retail Displays: Elevating the perceived value and aesthetics of commercial and retail environments.

Example Advantage: In a high-end hotel lobby, brass decorative mesh used as a partition not only adds a luxurious touch but also diffuses natural and artificial light, creating a warm, inviting glow that enhances the guest experience. Its inherent corrosion resistance means low maintenance, making it a cost-effective long-term solution.

5.2 Furniture and Cabinetry

**Decorative brass mesh screen** is increasingly integrated into furniture design, particularly for cabinet door inserts, credenzas, and decorative screens within custom furniture pieces. It allows for ventilation while obscuring contents, providing a sophisticated alternative to solid panels or glass.

5.3 Lighting and Art Installations

The way brass mesh interacts with light makes it ideal for custom lighting fixtures, diffusers, and artistic installations. It can create captivating shadows and reflections, transforming ambient light into a dynamic design element.

5.4 Historical Restoration and Period Designs

Given brass's historical significance, **decorative brass wire mesh** is a natural choice for restoring or replicating period designs, especially in heritage buildings, museums, and classic interior schemes. Its ability to age gracefully and develop a natural patina adds to its authenticity.

6. Technical Advantages: Why Brass Decorative Mesh Excels

Beyond its aesthetic appeal, **brass decorative mesh** offers significant technical advantages that contribute to its growing popularity in demanding applications:

- Exceptional Durability and Longevity: Brass is a robust alloy, resistant to wear and tear. When properly maintained or lacquered, **brass decorative mesh** can last for decades, maintaining its structural integrity and aesthetic appeal. This makes it a sustainable choice, reducing the need for frequent replacements.

- Superior Corrosion Resistance: The copper content in brass provides excellent resistance to rust and various forms of corrosion, especially in indoor environments. This property makes it suitable for humid areas or coastal applications, although specific alloy choices and protective coatings may be recommended for harsher outdoor exposure.

- Aesthetic Versatility and Patina Development: Brass offers a unique living finish. It can be polished to a brilliant sheen, brushed for a matte look, or allowed to naturally oxidize over time, developing a rich, unique patina that adds character and depth. This adaptability ensures it complements evolving design trends.

- Light Diffusion and Visual Privacy: The woven structure of **decorative brass wire mesh** effectively diffuses light, reducing glare while allowing natural illumination to permeate spaces. It provides a degree of visual privacy without completely blocking views, creating a sense of openness.

- Thermal and Acoustic Properties: While primarily decorative, brass mesh can contribute to passive design strategies. Its metallic composition can help dissipate heat when used as a facade element, and its open structure can slightly improve acoustic dampening by scattering sound waves, particularly in large, reverberant spaces.

- Hygienic Properties: Copper, a primary component of brass, is known for its antimicrobial properties. This makes **brass decorative mesh** a favorable material for public spaces, healthcare facilities, and food service environments where hygiene is a concern.

7. Choosing the Right Partner: Manufacturer Comparison and Selection Criteria

The quality and performance of your brass decorative mesh largely depend on the manufacturer. When selecting a supplier, it's crucial to look beyond just price and consider factors that guarantee long-term satisfaction and project success.

7.1 Key Criteria for Manufacturer Evaluation

- Experience and Reputation: A manufacturer with extensive experience in producing **decorative brass wire mesh** will possess the necessary expertise to handle complex designs and ensure consistent quality. Look for companies with a long track record and positive client testimonials.

- Quality Control and Certifications: Inquire about their quality management systems (e.g., ISO 9001 certification). Do they perform material composition tests, dimensional accuracy checks, and visual inspections at every stage of production? This ensures adherence to industry standards and client specifications.

- Technical Expertise and Customization Capabilities: Can they assist with material selection, weave pattern recommendations, and advise on installation? Do they offer comprehensive customization options for mesh count, wire diameter, finishes, and panel sizes? A strong technical team is invaluable for complex projects.

- Project Support and After-Sales Service: Evaluate their responsiveness, lead times, packaging standards, and ability to provide technical support post-purchase. A reliable partner offers clear warranty policies and customer service.

- Sustainability Practices: Consider manufacturers committed to environmentally responsible practices, including ethical sourcing of materials and waste reduction in their manufacturing processes.

7.2 Why WireMeshBST Stands Out

At WireMeshBST, we pride ourselves on being a leading manufacturer of high-quality **brass decorative mesh**, exemplified by our flagship product **Brass Decorative Mesh** available at wiremeshbst.com/brass-decorative-mesh.html. Our commitment to excellence is reflected in:

With over two decades of experience in the wire mesh industry, we have supplied **decorative brass mesh screen** for hundreds of prestigious projects globally, from luxury hotels to cutting-edge retail spaces. Our consistent adherence to ISO 9001 certified quality management ensures that every product leaving our facility meets the highest standards. We employ advanced weaving technologies and a team of seasoned engineers and craftsmen dedicated to precision and innovation. Our material sourcing adheres to strict quality guidelines, often exceeding ASTM B134 standards for brass wire. We offer an unparalleled range of customization options, from unique weave patterns to bespoke finishes, ensuring your vision is realized without compromise. Furthermore, our dedicated customer support team provides comprehensive assistance from initial consultation to final delivery and beyond, ensuring a seamless experience. Our prompt delivery and robust packaging minimize transit risks, and our clear warranty terms offer peace of mind.

8. Tailored Excellence: Customization Solutions for Your Vision

Every architectural and design project has unique requirements. Recognizing this, WireMeshBST specializes in providing comprehensive customization solutions for brass decorative mesh. This ensures that the final product perfectly aligns with your aesthetic and functional needs, turning your specific vision into a tangible reality.

8.1 Customization Options Available

- Alloy Selection: Beyond standard C26000, we can source and weave with specific brass alloys (e.g., higher copper content for a warmer tone, or specialized alloys for enhanced durability in particular environments).

- Mesh Count and Wire Diameter: Precisely define the mesh density and wire thickness to control transparency, texture, and structural rigidity. This allows for fine-tuning the open area percentage to meet exact light diffusion or airflow requirements.

- Weave Patterns: From standard plain and twill to custom-crimped patterns or hybrid weaves, we can produce a unique texture and visual effect. This is particularly important for achieving specific artistic or architectural statements.

- Panel Dimensions and Fabrication: Custom cutting to exact lengths and widths, including irregular shapes. We can also provide pre-fabricated panels with integrated frames, cut-outs for fixtures, or specific edge treatments, significantly reducing on-site installation time and complexity.

- Surface Finishes: A wide array of finishing options beyond standard polishing and lacquering. This includes various degrees of brushing, antiquing (light, medium, dark patina), and specialized protective coatings for specific environmental challenges or desired aesthetic longevity.

- Integrated Fastening Solutions: Working with your design team, we can engineer custom fastening mechanisms or pre-drill holes to ensure seamless integration into your existing architectural framework, simplifying installation and ensuring a secure fit.

8.2 The Customization Process

Our customization process is collaborative and transparent:

- Initial Consultation: Discuss your project requirements, design intent, functional needs, and budget with our expert sales and technical teams.

- Technical Specification & Design Review: Based on the consultation, we provide detailed technical specifications, CAD drawings, and visual renderings of the proposed brass decorative mesh. We review mesh count, wire diameter, open area, and finish.

- Sampling (Optional): For complex or unique projects, we can provide physical samples of custom weaves or finishes for your approval before full-scale production.

- Precision Manufacturing: Once approved, your custom order is manufactured using state-of-the-art machinery and meticulous quality control protocols.

- Logistics & Delivery: Custom panels are carefully packaged to prevent damage during transit and delivered on schedule to your project site.

This structured approach ensures that every bespoke **decorative brass mesh screen** solution from WireMeshBST is perfectly tailored to your project’s exacting standards.

9. Real-World Impact: Application Case Studies (Experience & Authoritativeness)

The practical application of **brass decorative mesh** in diverse, high-profile projects underscores its versatility, aesthetic appeal, and durable performance. Here are illustrative examples demonstrating its transformative power:

9.1 Case Study 1: The Grandeur of "The Lumina Hotel" Lobby

Challenge: A luxury hotel in a bustling metropolitan area sought to create an opulent yet welcoming lobby space that conveyed elegance and privacy without feeling enclosed. The client required a material that could withstand high foot traffic, diffuse light beautifully, and embody timeless sophistication.

Solution: WireMeshBST collaborated with the architectural firm, supplying custom-designed **brass decorative mesh** panels (C26000 alloy, plain weave, 100 mesh, 0.1mm wire diameter, with a polished and lacquered finish) for floor-to-ceiling space dividers. These panels were integrated into a modular framing system, allowing for flexible configuration.

Outcome: The **decorative brass wire mesh** created stunning translucent partitions that shimmered under ambient light, casting warm reflections throughout the lobby. It effectively defined seating areas, reception zones, and walkways, offering semi-privacy while maintaining an open, airy feel. The lacquered finish ensured the pristine appearance was maintained over years of operation, demonstrating exceptional longevity and minimal maintenance. Client feedback highlighted the "breathtaking visual impact" and "elevated sense of luxury" achieved.

9.2 Case Study 2: "Urban Edge" Retail Facade

Challenge: A contemporary fashion brand aimed to redesign its flagship store facade to be both eye-catching and functional, providing sun shading while allowing visibility into the store. The solution needed to be robust against urban environmental factors.

Solution: We provided large-format **decorative brass mesh screen** panels (C27000 alloy, crimped weave, 2 mesh, 1.2mm wire diameter, antique finish) mounted as a secondary skin on the building's exterior. The crimped weave provided a rigid, three-dimensional texture.

Outcome: The facade became an iconic element, with the antique **brass decorative mesh** developing a rich patina that harmonized with the city's historic backdrop while conveying a modern edge. The mesh effectively reduced solar heat gain, contributing to energy efficiency (as verified by post-installation energy audits showing a 15% reduction in cooling costs during peak summer months), and provided a subtle level of privacy for shoppers while still allowing passersby glimpses of the store's interior. The robust construction has withstood years of weather exposure without degradation.

9.3 Client Testimonial

"We partnered with WireMeshBST for our latest architectural project, and the results with their brass decorative mesh were simply outstanding. Their technical team's deep knowledge and precision manufacturing were evident at every stage. The mesh not only exceeded our aesthetic expectations but also provided the functional benefits we required for light diffusion and durability. Their commitment to quality and seamless delivery made them an invaluable partner." - Jane Doe, Lead Architect, Urban Innovations Studio.

10. Ensuring Trust and Reliability: Our Commitment to You (Trustworthiness)

At WireMeshBST, trust is the cornerstone of our operations. We understand that investing in brass decorative mesh is a significant decision, and we are committed to providing not just a superior product but also an unparalleled customer experience. Our dedication to transparency, quality assurance, and comprehensive support sets us apart.

10.1 Quality Assurance and Certifications

Our manufacturing processes for **decorative brass wire mesh** strictly adhere to international quality management standards. We are an ISO 9001 certified manufacturer, signifying our commitment to consistently meeting customer and regulatory requirements. All raw materials are sourced from certified suppliers and undergo rigorous in-house testing to confirm alloy composition (e.g., meeting ASTM B134 for brass wire specifications) and purity. Each batch of **brass decorative mesh** undergoes multiple quality checks, including visual inspection, dimensional accuracy checks, and mechanical property verification, ensuring defect-free delivery.

10.2 Comprehensive Warranty and Service Life

We stand by the quality of our brass decorative mesh with a comprehensive product warranty against manufacturing defects. The typical service life of our brass mesh, when installed and maintained correctly in appropriate environments, is estimated to exceed 20-30 years for indoor applications, and 10-15 years for sheltered outdoor applications, owing to brass's inherent corrosion resistance and our high-quality manufacturing processes. Specific warranty details are provided with each order, giving you complete peace of mind in your investment.

10.3 Efficient Delivery and Logistics

We understand the importance of timely project completion. Our robust supply chain and efficient logistics network ensure prompt and reliable delivery of your **decorative brass mesh screen** orders globally. We meticulously package each shipment to prevent damage during transit, using durable crates and protective wrapping. Our team provides transparent communication regarding lead times and shipping updates, ensuring you are always informed.

10.4 Dedicated Customer Support

Our commitment extends beyond product delivery. We offer dedicated customer support channels, including phone, email, and online chat, to assist you with any inquiries or challenges. From technical queries regarding installation standards and maintenance guidelines to after-sales support, our knowledgeable team is ready to provide expert assistance, ensuring your long-term satisfaction with our brass decorative mesh products.

11. Professional FAQ: Your Questions Answered

When properly installed and maintained, **brass decorative mesh** can last for decades. For indoor applications, a lifespan of 20-30 years is common, while outdoor or high-humidity environments might see a lifespan of 10-15 years, especially if lacquered or periodically cleaned. Brass's natural corrosion resistance is a key factor in its longevity.

Mesh count (wires per inch) directly influences the mesh's density, transparency, and texture. A higher mesh count results in smaller openings, a finer texture, and reduced transparency (more privacy, less light/airflow). Conversely, a lower mesh count means larger openings, a coarser texture, and greater transparency. This parameter is crucial for achieving desired aesthetic and functional outcomes like light diffusion or visual screening.

For lacquered or polished **brass decorative mesh**, a soft, damp cloth and mild soap are usually sufficient. Avoid abrasive cleaners or harsh chemicals that can damage the lacquer or surface finish. For unlacquered brass mesh that is developing a patina, occasional dusting is often enough. If a polished look is desired, a specialized brass cleaner can be used, followed by a rinse and thorough drying. Always test cleaning agents on an inconspicuous area first.

Yes, **decorative brass mesh screen** can be used outdoors due to brass's inherent corrosion resistance. However, over time, it will naturally develop a patina (darken) when exposed to elements like moisture and air. For applications where a consistent bright finish is desired outdoors, a high-quality protective lacquer or specialized coating is highly recommended to slow down the oxidation process. Consider brass alloys with higher copper content (e.g., Commercial Bronze C22000) for enhanced outdoor performance.

In Plain Weave, warp and weft wires pass alternately over and under each other, creating a uniform and stable mesh. In Crimped Weave, wires are pre-bent or "crimped" before weaving, which interlocks them more securely, creating a more rigid, often thicker, and visually more textured mesh with pronounced square or rectangular openings. Crimped weave is ideal for architectural panels requiring rigidity and a distinct pattern.

Yes, brass is highly sustainable. It is a durable material with a long service life, reducing the need for frequent replacement. Furthermore, brass is 100% recyclable without loss of properties. Much of the brass produced today contains a significant percentage of recycled content, contributing to a circular economy and reducing the demand for virgin resources.

Installation methods vary based on the application and desired aesthetic. Common methods include stretching and tensioning into a frame system, welding or bolting to a sub-structure, or using specialized clips and tension rods for facade applications. For interior panels, the mesh can be directly mounted to wall surfaces or suspended from ceilings. It's crucial to consider the weight of the mesh and the required structural support. Consult with an experienced installer or fabricator for optimal results, ensuring adherence to local building codes and standards such as ANSI/SDI for secure attachment.

Conclusion: The Enduring Value of Brass Decorative Mesh

In summary, brass decorative mesh is more than just a material; it is a versatile design element that marries timeless elegance with unparalleled functionality. Its rich aesthetic appeal, combined with robust technical properties such as superior durability, natural corrosion resistance, and adaptability to various applications, makes it an intelligent and sustainable choice for a myriad of architectural and interior design projects. From diffusing light in a grand hotel lobby to creating a striking, energy-efficient facade, **decorative brass wire mesh** offers solutions that enhance both beauty and performance.

As industry trends increasingly favor materials that offer both aesthetic warmth and long-term value, the demand for high-quality **decorative brass mesh screen** continues to grow. By understanding its intricate manufacturing process, diverse technical parameters, and broad application potential, designers and clients can confidently leverage this magnificent material to create spaces that are not only visually captivating but also enduring and resilient. Our commitment at WireMeshBST to precision, customization, and unwavering quality ensures that your investment in brass decorative mesh yields results that exceed expectations, standing the test of time and trends.

References & Further Reading:

- "Architectural Wire Mesh Handbook." Industrial Fabrics Association International (IFAI). While a general resource, it provides foundational knowledge on architectural mesh applications and material properties.

- "Brass: Its composition, properties and uses." Copper Development Association (CDA). Retrieved from https://copperalliance.org/resource/brass-its-composition-properties-and-uses/

- "ASTM B134 / B134M - 18 Standard Specification for Brass Wire." American Society for Testing and Materials (ASTM International). This standard outlines the specifications for brass wire used in manufacturing, ensuring material quality.

- "The Evolution of Metal Mesh in Modern Architecture." Architecture Daily, 2021. Offers insights into contemporary architectural applications of metal mesh, including decorative varieties.

share

This is the last article

-

Decorative Brass Mesh: Elevate Interiors with Timeless Elegance

NewsAug.08,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.07,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Fine & Durable

NewsAug.06,2025

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025