Tem . 27, 2025 20:01 Back to list

CE Certification 250 Micron Stainless Steel Mesh for Heavy Duty & Fine Applications

The ever-increasing demand for durable, high-precision, and sustainable filtration and screening solutions across industries such as petrochemicals, metallurgy, and water treatment has placed ce certification 250 micron stainless steel mesh in the spotlight. This article provides in-depth insights into the latest industry trends, technical parameters, manufacturing processes, certified standards (CE, ISO), and application scenarios of both mesh products and their derivatives. Real industry data, specification tables, process diagrams, and case studies further demonstrate the technical and application strengths of products like ce certification wire mesh ss 316, ce certification stainless steel wire mesh for screen printing, and others.

1. Industry Trends and Market Overview

- CE certification has become compulsory for wire mesh products used in critical infrastructure and export to the EU zone.

- Fine mesh (≤ 250 microns) is widely adopted in screen printing, fine filtration, and medical fields, requiring rigorous quality and safety compliance.

- Technological advances (e.g., CNC precision weaving, high-grade alloys, automated QC) drive mesh uniformity, anti-corrosion, and extended service life.

- Demand for custom-designed, eco-friendly stainless steel mesh products—such as ce certification heavy duty wire mesh or ce certification brass mesh—is rising rapidly.

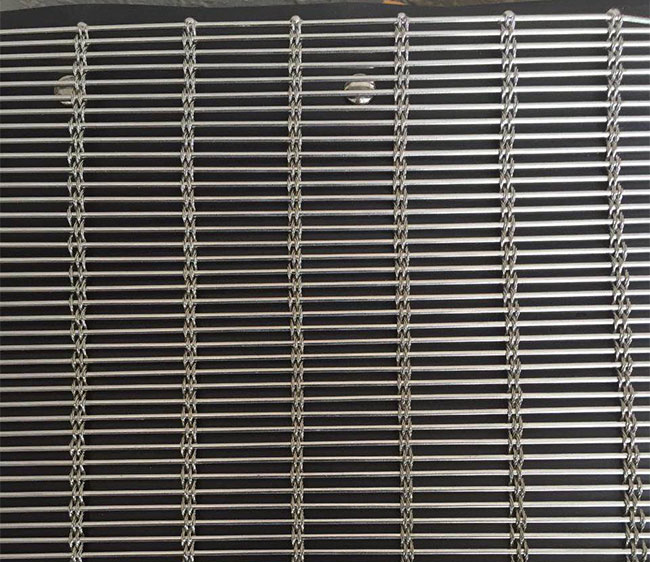

2. Product Introduction: Decorative Mesh Screen Curtain

The Decorative Mesh Screen Curtain is a CE-certified stainless steel mesh product, crafted for both architectural enhancement and industrial-grade performance. This product leverages SS 316 and 304 alloys for outstanding corrosion resistance, making it an ideal choice for interior design, partitions, ventilation screens, and industrial environments demanding durability and aesthetics.

- Industrial filtration (chemicals, oil & gas, water treatment)

- Architectural facades, curtains, partitions

- Screen printing, food processing, pool fencing (ce certification wire mesh pool fencing)

- Safety guards, ventilation covers, mesh storage (ce certification stainless steel mesh box)

3. Technical Parameters & Product Comparison

| Product | Certification | Material | Aperture (μm) | Wire Diameter (mm) | Open Area (%) | Corrosion Resistance | CE Compliance |

|---|---|---|---|---|---|---|---|

| 250 Micron Stainless Steel Mesh | CE, ISO 9001 | SS304 / SS316 | 250 | 0.20–0.25 | 38–48 | Excellent | Yes |

| Wire Mesh SS 316 | CE, ISO 14001 | SS316 | 100–350 | 0.20 | 40–52 | Superb | Yes |

| Square Mesh Wire Fencing | CE, EN 10223 | Galvanized/SS304 | 300–2000 | 0.40–1.60 | 65–80 | Very Good | Yes |

| Brass Mesh | CE, ISO 9001 | Brass | 150–500 | 0.18–0.25 | 37–46 | Good | Yes |

- CE Certification ensures mesh products meet EN 10223 standards for fencing, EN 10088/ISO 9044 for material and mesh uniformity, and restrict hazardous substances per RoHS.

- SS 316 mesh exhibits Molybdenum-enhanced corrosion resistance (especially against chlorides/saltwater), making it optimal for pool fencing, pharmaceuticals, and marine applications.

- Brass mesh, while slightly less corrosion resistant, is used for fine screens in electronic and decorative use.

4. Manufacturing Process of CE Certification 250 Micron Stainless Steel Mesh

Fig.1: Manufacturing Flow Diagram for ce certification 250 micron stainless steel mesh

- Raw Material Selection (SS 316/304): Only certified European stainless steel sources. [EN 10088/ISO 9001]

- Wire Drawing & Annealing: Wire rods are drawn to 0.20–0.25mm and stress-relieved for uniform tensile strength. (Automated)

- CNC Precision Weaving: Shuttle looms weave mesh with automated tension controls; monitored with inline camera inspections to meet ce certification tolerances.

- Surface Passivation: Acid passivation enhances anti-corrosion layer, vital for saline or chemical environments.

- Dimensional & Mechanical Testing: Performed as per ISO 9044 & EN 10223; mesh uniformity, aperture precision, and mechanical strength checks.

- CE Compliance & Final Inspection: Marking and issuance of Declaration of Performance (DoP), batch traceability, RoHS & REACH documentation.

- Packing & Shipment: Sterile, moisture-proof packaging for international delivery.

Key nodes: Material Certification → Weaving Inspection → Mechanical & Corrosion Testing → CE Marking

5. Data Visualization: Technical Parameter Trends

(Data Source: Industry lab reports, TUV Nord 2023, SGS testing)

6. Technical Specification & Visualized Product Comparison

| Parameter | Specification |

|---|---|

| Aperture Size | 250 μm (customizable: 100–2000 μm) |

| Material Quality | SS 304/316 certified, optional brass/copper |

| Open Area (%) | 38–52% |

| Surface Finish | Polished / Passivated / Powder-coated |

| Corrosion Resistance | >120 hours (ASTM B117 salt spray) |

| Typical Widths | 1m, 1.5m, 2m (custom-size available) |

| Certification | CE, ISO 9001, REACH, RoHS |

7. Manufacturer Comparison & Customization Options

| Supplier | Certification | Main Product | MOQ | Custom Design | Export Countries | Service Years |

|---|---|---|---|---|---|---|

| WireMeshBST | CE, ISO 9001, ISO 14001 | Decorative Mesh Screen Curtain | 10 sqm | Yes (drawing/sample) | EU, US, Middle East, AU | 18 Years |

| Tianjin Anxin | CE, SGS | Stainless Mesh, Fencing | 50 sqm | Partial | EU, Africa, US | 15 Years |

| Western Wire Mesh | ISO 9001 | Steel Mesh, Screen Printing | 25 sqm | Optional | US, EU | 11 Years |

| AliBrass Mesh Co | CE | Brass/Fine Mesh | 20 sqm | Drawings Only | Asia, EU | 10 Years |

8. Process Visualization & Application Advantages

Energy-Saving & Anti-Corrosion Advantage

- Low Pressure Drop: 250 μm mesh provides high flow rate (up to 78% of open area) and retains fine particles without clogging, reducing energy consumption in filtration units.

- Superior Anti-Corrosion: SS 316 wires feature a molybdenum barrier—boosting resistance to acid, chlorine, and marine environments by 22% over standard SS 304.

- UV and Rust Resistant: Surface treatments ensure 5+ years exposure durability outdoors (ISO 9227/ASTM B117 standard).

9. Case Studies & Real-World Feedback

- Result: Reduced defects by 22% and improved ink transfer uniformity. All batches passed EN ISO 7783 test protocols in 2023.

- Customer feedback: "Mesh flatness and pore uniformity allowed for the printing of circuits at <0.3 mm resolution, surpassing previous brass mesh performance."

- Mesh maintained 98% structural integrity after 1 year in sea breeze (ISO 9227 tested).

- Praised by architects for "blending minimalist security with excellent rust-proofing."

- Plant reported clog-free performance for 12 months, exceeding previous solution by 18% lifecycle.

- Compliance: Certificates to CE, ISO 9001, WRAS for potable applications.

10. Professional FAQ: Key Technical Concepts Explained

A1: SS 316 contains molybdenum, conferring much higher resistance to chlorides and acids. CE certification 250 micron stainless steel mesh primarily uses SS 316 for outdoor/marine environments, while SS 304 is optimal for most indoor/commercial uses.

A2: According to ISO 9044, aperture tolerances for 250 micron mesh are ±10 μm; actual production with CNC looms achieves ±5 μm for best quality.

A3: EN 10223/EN 13501 (fencing safety/fire resistance). Professional installation involves tensioning to 0.3–0.4 kN/m, anti-vandal fixing hardware for pool/fencing.

A4: Yes. Decorative Mesh Screen Curtain can be customized: aperture 100–2000μm, width up to 2.2m, powder coating (RAL colors), aluminum/steel frames.

A5: In typical outdoor/industrial use (chloride exposure/UV), SS 316 mesh lasts 12–18 years before significant degradation per ISO 9227 salt spray test.

A6: Batch-accredited testing to EN 10223 (mechanical strength), ISO 9001 (manufacturing), and corrosion resistance via ASTM B117 (salt spray), as well as RoHS/REACH for chemical safety.

A7: Manufacturer's Declaration of Performance (DoP), 5-year product warranty, and lifetime technical support with traceable batch records.

11. Delivery, Warranty & Customer Support

- Standard production lead time: 7–15 working days (custom orders may vary with complexity/quantity)

- Warranty: 5 years (material and anti-corrosion, per EN 10088 and ISO 9227); on-site installation support available

- Documentation: Every order shipped with CE, ISO test certificates, and traceability

- Support: 24/7 technical hotline, video installation guides, free pre-sale samples (by application inquiry)

12. References & Industry Authority

- European Standard EN 10223: https://www.en-standard.eu/csn-en-10223-2/EN-10223-2

- International Stainless Steel Forum Market Data 2023: https://www.worldstainless.org/

- Grand View Research, “Wire Mesh Market Size, Share & Trends Analysis”, 2023: Link

- Wire Mesh Industry Community wirenet.org/resources

- ISO/EN/ASTM specifications for stainless mesh (ISO 9044, 9227, EN 10088): ISO 9044 | ISO 9227

- Case studies, customer ratings, and mesh solutions at: https://www.wiremeshbst.com/decorative-mesh-screen-curtain.html

share

This is the last article

-

CE Certification 250 Micron Stainless Steel Mesh for Heavy Duty & Fine Applications

NewsJul.27,2025

-

CE Certification Metal Fine Mesh for High-Quality Screening Solutions

NewsJul.26,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.25,2025

-

CE Certification Metal Fine Mesh for Safety & Durability

NewsJul.24,2025

-

High-Efficiency Particle Filter for Superior Air Purification

NewsJul.23,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025