Сер . 17, 2025 00:40 Back to list

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

Understanding High-Strength Screening Wire Mesh and Its Market Dynamics

In the intricate world of industrial processing, the efficiency and precision of material separation hinge significantly on the quality of screening media. High-strength screening wire mesh stands as a critical component, engineered to withstand extreme conditions while delivering unparalleled performance in various demanding applications. These meshes are not merely filters; they are sophisticated engineering products designed for longevity, resistance to wear, corrosion, and high impact, ensuring optimal throughput and reduced downtime. Factors influencing their adoption range from specific mesh aperture requirements—such as those defining a 1 4 wire mesh screen or a 1 8 inch wire mesh screen—to the material's inherent strength and its capacity to manage diverse material types, from fine powders to coarse aggregates. The choice of mesh directly impacts operational efficiency and overall processing costs within sectors ranging from petrochemical and metallurgy to water treatment and mineral processing.

The market for high-strength screen mesh price is influenced by a confluence of variables, including raw material costs, manufacturing complexity, specialized treatments, and global supply chain dynamics. Companies seeking to optimize their procurement strategies must look beyond the initial purchase price, considering the total cost of ownership (TCO) which encompasses durability, maintenance, and replacement frequency. For instance, a 1 2 inch wire mesh screen used in heavy-duty aggregate screening will demand different material specifications and manufacturing precision than a finer mesh applied in chemical filtration. Industry trends show a consistent move towards higher performance materials, such as stainless steel alloys, high carbon steel, and specialized synthetic polymers, each selected for their unique properties like enhanced tensile strength, abrasion resistance, or anti-blinding characteristics. This evolution is driven by the increasing need for finer separation, greater throughput, and reduced environmental impact in sectors like mining, petrochemical, and waste management. Understanding these underlying factors is crucial for making informed purchasing decisions and securing the best value for robust, high-performance screening solutions.

The Advanced Manufacturing Process of High-Strength Screening Wire Mesh

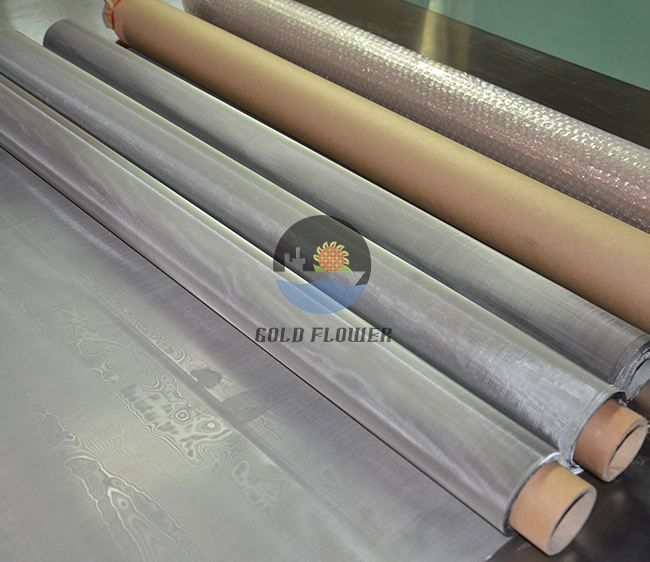

The production of High-strength Screening Wire Mesh is a sophisticated multi-stage process that begins with the meticulous selection of premium raw materials. Typical materials include high-carbon steel, spring steel, stainless steel (e.g., 304, 316, 316L for superior corrosion resistance), and specialized alloys like manganese steel for extreme abrasion resistance. The initial stage involves precision wire drawing, where rods are drawn through dies to achieve the exact wire diameter required for optimal mesh stability and performance. This is followed by crimping, a crucial step for producing woven meshes. Wires are precisely corrugated or crimped to ensure that the mesh wires interlock securely and maintain uniform aperture sizes, even under severe vibratory stress. The crimping pattern—whether double crimp, intermediate crimp, or lock crimp—is chosen based on the desired stability and filtering efficiency. This meticulous preparation directly impacts the final structural integrity and functional lifespan of the screening wire mesh, underpinning its ultimate value.

Following wire preparation, the weaving process commences on specialized looms. Depending on the application, various weave patterns are employed, such as plain weave for general filtration, twill weave for higher strength and finer filtration, or Dutch weave for superior particle retention and high-pressure applications. Each weaving technique contributes to the mesh's specific characteristics, influencing factors like open area, flow rate, and particle size cut-off. For certain high-strength applications, a welding process may be used, creating a rigid structure with consistent square or rectangular apertures. Post-weaving or welding, the mesh undergoes rigorous quality control. This includes visual inspections, dimensional checks (ensuring precise mesh aperture and wire diameter), and material property tests. Adherence to international standards such as ISO 9001 for quality management, and ASTM (American Society for Testing and Materials) standards for material properties and testing methods, is paramount. For instance, a screening mesh destined for the petrochemical industry might undergo NDT (Non-Destructive Testing) or specific corrosion resistance tests to ensure compliance with stringent safety and operational requirements, validating the investment in the screen mesh price.

The final stages involve finishing treatments and custom fabrication. This can include heat treatment to enhance material hardness or flexibility, coating applications (e.g., PVC coating for corrosion protection or polyurethane for impact absorption), and precise cutting, bending, or welding to form specific screen panels or vibratory screen sections. The expected service life of high-strength screening mesh can range from several months in highly abrasive environments to many years in less demanding applications, significantly impacting the long-term screen mesh price. In industries like metallurgy, mining, and aggregates, the mesh is crucial for efficient particle sizing and material classification, contributing to improved product quality and reduced energy consumption by optimizing separation processes. For instance, in wastewater treatment, specific meshes prevent clogging and ensure clean effluent. These meticulous manufacturing steps ensure that each product, whether a durable 1 4 wire mesh screen for heavy mining or a precise 1 8 inch wire mesh screen for fine chemical processing, delivers optimal performance and cost-effectiveness. Our commitment to ISO and ANSI standards guarantees consistent quality and reliability, making us a trusted partner for B2B procurement.

Key Technical Parameters and Factors Influencing Screen Mesh Price

When evaluating the screen mesh price, it is imperative to delve into the technical parameters that dictate its cost and performance. These parameters include the material composition, wire diameter, mesh count (number of openings per linear inch), aperture size, weave pattern, and overall dimensions. For instance, stainless steel meshes, particularly those made from 316L, command a higher price due to their superior corrosion resistance and longevity, crucial in chemical processing or marine environments. Conversely, a standard high-carbon steel mesh might offer a more economical upfront cost but could require more frequent replacement in abrasive applications. The wire diameter is equally critical; thicker wires contribute to greater strength and abrasion resistance, albeit at the expense of open area and potentially higher material cost. A heavy-duty 1 2 inch wire mesh screen, for example, will use significantly thicker wires than a finer mesh, reflecting in its screen mesh price.

Mesh count and aperture size are directly related to the precision of separation and filtration. A higher mesh count implies finer openings and a more complex weaving process, consequently increasing the cost. For example, a specialized 1 8 inch wire mesh screen designed for fine particle separation will typically have a higher unit cost per square foot compared to a coarser mesh like a 1 4 wire mesh screen used for primary sizing. The weave pattern—be it plain, twill, or Dutch weave—also plays a significant role; more intricate weaves, which offer enhanced strength or filtration characteristics, involve higher manufacturing complexity and thus higher production costs. Furthermore, any specialized treatments such as heat treatment, calendaring (flattening to achieve precise thickness), or coating applications (e.g., epoxy, polyurethane) add to the overall screen mesh price by enhancing the mesh's performance attributes like anti-blinding properties or chemical inertness. Understanding these technical nuances allows B2B buyers to align their investment with their operational needs, ensuring optimal performance and cost-efficiency over the product's lifecycle.

Comparative Analysis: Factors Influencing Screen Mesh Price

| Factor | Description | Impact on Screen Mesh Price (Relative) |

|---|---|---|

| Material Type | High Carbon Steel, Stainless Steel (304, 316L), Manganese Steel, Polyurethane. | Low to High (HCS < 304 < Manganese < 316L < Polyurethane) |

| Wire Diameter | Thickness of individual wires (e.g., 2.0mm to 12.0mm). | Higher diameter = Higher Price (More material used) |

| Mesh Aperture (Opening Size) | Size of the opening (e.g., 2mm to 100mm+). | Finer Aperture = Higher Price (More wires per area, tighter tolerance) |

| Weave Pattern | Plain, Twill, Dutch, Reverse Dutch. | Plain < Twill < Dutch (Complexity of weaving) |

| Panel Dimensions & Configuration | Overall length and width, specialized hooks/edges. | Larger/Custom = Higher Price (More material, specialized fabrication) |

| Surface Treatment/Coating | Polyurethane coating, PVC coating, galvanization, heat treatment. | Adds to Price (Enhances performance/lifespan) |

| Order Quantity | Volume of purchase. | Higher Quantity = Lower Unit Price (Economies of scale) |

Applications and Technical Advantages of High-Strength Screening Wire Mesh

High-strength screening wire mesh is indispensable across a multitude of heavy industrial sectors due to its superior durability and precise separation capabilities. In mining and quarrying, these meshes are vital for classifying raw materials like coal, iron ore, gravel, and sand. For instance, a robust 1 4 wire mesh screen or 1 2 inch wire mesh screen is typically deployed on vibratory screens to separate large aggregates, ensuring uniform particle sizing for construction or further processing. The ability of these meshes to withstand abrasive materials and continuous vibration significantly reduces wear and tear, thereby minimizing downtime and replacement costs, which directly impacts the long-term screen mesh price effectiveness. In metallurgy, they are used for processing slag, foundry sands, and metal powders, where high temperatures and corrosive environments demand materials like stainless steel or specialized alloys that retain integrity under extreme conditions.

Beyond aggregates and metallurgy, these meshes find critical applications in petrochemical industries for catalyst support, fluidization, and fine particle separation in refining processes, where resistance to corrosive chemicals and high pressures is paramount. A precisely engineered 1 8 inch wire mesh screen might be used in these scenarios for fine filtration. In wastewater treatment and municipal solid waste management, robust screening wire mesh plays a crucial role in removing solids from liquids or sorting various waste streams, ensuring environmental compliance and resource recovery. The technical advantages of our High-strength Screening Wire Mesh are manifold: engineered for superior tensile strength and impact resistance, they offer extended service life even in the most aggressive operational settings, translating into significant cost savings for our clients. Their optimized open area ensures high throughput and efficient material flow, reducing energy consumption in screening operations. Furthermore, the precision of our manufacturing process minimizes blinding and clogging, particularly critical for fine screening wire mesh applications, ensuring consistent performance and minimizing operational interruptions.

Our meshes are specifically designed to be energy-efficient by enabling higher processing capacities with fewer machine cycles, contributing to reduced carbon footprints and operational costs. Their exceptional corrosion and abrasion resistance ensure consistent performance and extended lifespan, even when exposed to harsh chemicals or highly abrasive materials. For example, a client in the aggregate industry reported a 30% increase in screen panel lifespan and a 15% reduction in energy consumption after switching to our High-strength Screening Wire Mesh, directly impacting their long-term screen mesh price. This not only underscores the superior performance but also the tangible economic benefits of investing in high-quality products. We offer customized solutions, from specific mesh dimensions and aperture sizes to tailored material compositions and edge preparations, ensuring each product perfectly fits the client's unique machinery and operational requirements. Our engineering team collaborates closely with clients to develop bespoke screening solutions that optimize their processes, illustrating our commitment to delivering value beyond the mere product.

Ensuring Trustworthiness: FAQs, Delivery, and Warranty

Building trust in the B2B sector for specialized products like high-strength screening wire mesh requires transparency and robust support systems. Our commitment to trustworthiness is reflected in our adherence to global quality standards and our customer-centric service model. We hold ISO 9001 certification, a testament to our consistent quality management systems and continuous improvement processes. Our products are tested rigorously to meet or exceed ASTM and ANSI standards, ensuring reliability and performance under demanding industrial conditions. With over two decades of experience in the wire mesh industry, we have cultivated partnerships with leading manufacturers and end-users worldwide, delivering solutions that stand the test of time. Our extensive service history and numerous successful application cases across diverse industries, from large-scale mining operations to precise chemical filtration, underscore our authoritative position in the market. This long-standing reputation for quality and reliability directly influences the perceived value and competitiveness of our screen mesh price.

Frequently Asked Questions (FAQs)

-

Q: How does wire diameter affect the screen mesh price?

A: Generally, a larger wire diameter means more material is used and requires specialized manufacturing equipment, leading to a higher unit price. However, thicker wires also contribute to increased strength and longevity, potentially reducing long-term replacement costs and improving overall value. -

Q: What is the typical lead time for custom screening wire mesh orders?

A: For standard products, our lead time typically ranges from 2-4 weeks. For highly customized solutions or very large orders, the lead time may extend to 4-8 weeks, depending on material availability and production complexity. We communicate clear timelines at the point of order confirmation to ensure transparency. -

Q: Do you offer a warranty on your High-strength Screening Wire Mesh?

A: Yes, we provide a 1-year limited warranty on our High-strength Screening Wire Mesh, covering defects in material and workmanship under normal operating conditions. Our commitment extends beyond the sale through dedicated technical support and after-sales service to ensure customer satisfaction and product longevity, thereby guaranteeing the long-term value of your screen mesh price.

Our standard delivery cycle for stock items is approximately 2-3 weeks, while custom orders typically require 4-6 weeks, allowing for precise manufacturing and rigorous quality checks. We maintain transparent communication throughout the production and delivery phases, providing regular updates to our clients. Every product shipped is accompanied by a comprehensive quality assurance certificate, detailing material composition, manufacturing tolerances, and compliance with specified standards. Our dedicated customer support team is available to assist with technical queries, order tracking, and any post-delivery requirements, reinforcing our commitment to a seamless customer experience. We aim to ensure that our customers not only receive a superior product but also benefit from unparalleled service, justifying every aspect of the screen mesh price.

Customized Solutions and Case Studies for Optimizing Screen Mesh Value

Recognizing that every industrial application presents unique challenges, we specialize in providing tailored screening solutions designed to meet specific performance requirements and budget constraints. Our approach begins with a comprehensive consultation, where our technical experts collaborate with clients to understand their exact operational environment, material characteristics, desired separation efficiency, and equipment specifications. This collaborative process allows us to recommend the optimal wire material, mesh aperture, wire diameter, and weave pattern. For instance, for an application requiring extreme abrasion resistance, we might suggest manganese steel wire mesh, even if its initial screen mesh price is higher, due to its proven track record of significantly longer lifespan and reduced replacement frequency compared to conventional materials. Our ability to customize edge preparations, hook types, and panel dimensions ensures seamless integration with existing machinery, minimizing installation time and maximizing operational uptime.

A notable application case involved a large-scale aggregate processing plant facing persistent issues with premature wear of their vibratory screen panels, leading to frequent replacements and significant production losses. Their existing 1 2 inch wire mesh screen was lasting only three months in their highly abrasive gravel screening line. After a thorough on-site assessment, our engineers recommended a custom-designed screening wire mesh fabricated from high-tensile spring steel with a specialized crimp pattern. This solution, while having a slightly higher initial screen mesh price, extended the lifespan of their screen panels to over nine months, reducing annual replacement costs by 60% and improving overall plant productivity by minimizing changeover downtime. This example vividly illustrates how a strategic investment in a higher quality, precisely engineered solution leads to substantial long-term savings and operational gains, far outweighing the initial cost differential.

Another instance involved a client in the food processing industry needing extremely fine and hygienic separation for sugar crystals. Their previous supplier's 1 8 inch wire mesh screen frequently clogged, requiring manual cleaning and halting production. We engineered a specific 316L stainless steel mesh with a polished finish and a specialized twill Dutch weave, ensuring superior non-blinding properties and ease of cleaning, meeting strict FDA compliance. Though the unit screen mesh price was higher due to the material and precision, the client experienced a 40% reduction in cleaning time and a significant improvement in product purity, ultimately leading to a rapid return on investment and enhanced operational efficiency. These case studies underscore our capability to not just supply products, but to provide comprehensive solutions that drive tangible value and optimize our clients' total cost of ownership, reinforcing our position as a trusted partner in high-performance screening technology.

Concluding Insights: Strategic Investment in High-Performance Screening Solutions

The decision surrounding screen mesh price is far more complex than a simple upfront cost comparison. It represents a strategic investment in the operational efficiency, productivity, and long-term profitability of industrial processes. As demonstrated, factors such as material composition, precise manufacturing tolerances, application-specific designs, and the comprehensive support from the supplier all critically influence the true value proposition of screening wire mesh. Investing in high-strength, precisely engineered solutions, like our High-strength Screening Wire Mesh, translates into tangible benefits: extended service life, reduced downtime, lower energy consumption, and consistent product quality. These advantages significantly outweigh the initial investment, proving that a slightly higher screen mesh price for a superior product can yield substantial returns over time. Our commitment to meeting rigorous industry standards, coupled with our expertise in delivering customized solutions and reliable customer support, positions us as a dependable partner for businesses seeking to optimize their separation and filtration processes.

The evolving demands of modern industries necessitate screening media that can perform under increasingly challenging conditions while contributing to sustainability goals. From the robust 1 4 wire mesh screen in mining to the intricate 1 8 inch wire mesh screen in chemical filtration, the right mesh ensures peak operational performance. By prioritizing total cost of ownership over initial purchase price, and by collaborating with expert manufacturers who understand the nuances of material science and application engineering, businesses can unlock significant efficiencies and competitive advantages. We invite you to explore our range of High-strength Screening Wire Mesh and engage with our technical team to discover how our tailored solutions can enhance your operations and deliver exceptional value, ensuring your investment in screening wire mesh is not just a purchase, but a pathway to optimized performance and long-term success.

References

- ISO 9001: Quality management systems – Requirements. International Organization for Standardization.

- ASTM E2016: Standard Test Method for Performance of Wire Screens. ASTM International.

- Perry's Chemical Engineers' Handbook. McGraw-Hill Professional.

- SME Mining Engineering Handbook. Society for Mining, Metallurgy, and Exploration.

- Corrosion Resistance of Stainless Steels. NACE International.

share

This is the last article

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025