Août . 12, 2025 00:40 Back to list

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

Navigating the Landscape of CE Certified Metal Fine Mesh for Industrial Excellence

In today's highly regulated industrial landscape, the demand for compliant, high-performance materials is paramount. CE certification metal fine mesh stands as a critical component, offering superior filtration, separation, and structural integrity across diverse applications. This segment of the market is witnessing significant growth, driven by stringent safety standards, environmental regulations, and the increasing need for durable, corrosion-resistant materials. Industries such as petrochemicals, water treatment, food and beverage, pharmaceuticals, and architectural design are consistently seeking mesh solutions that not only meet performance specifications but also adhere to international compliance benchmarks like CE. The emphasis on quality assurance, traceability, and consistent manufacturing processes ensures that these products contribute to operational efficiency and long-term reliability. Understanding the nuances of material selection, perforation patterns, and the critical role of CE marking is essential for B2B procurement professionals and technical specifiers.

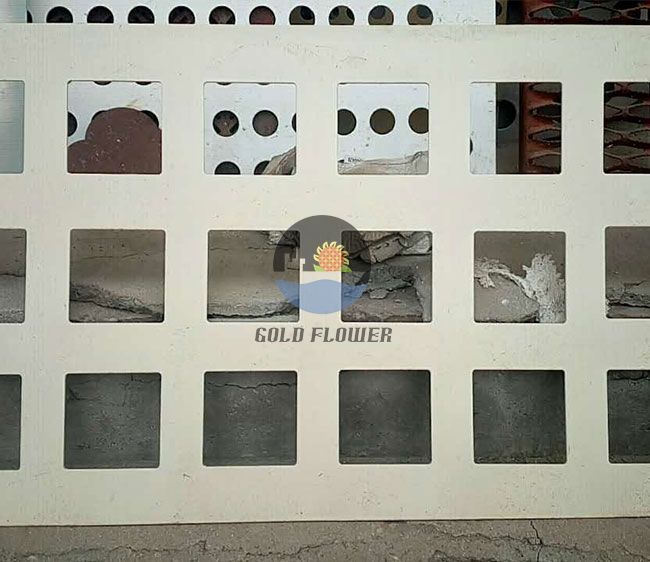

The market trend indicates a clear shift towards specialized metal mesh products, including those with intricate designs like other shapes perforated metal sheet, capable of withstanding extreme conditions while maintaining precise filtration capabilities. Innovations in material science have led to advancements in alloys that offer enhanced resistance to chemicals, high temperatures, and abrasive wear, expanding the applicability of fine mesh beyond traditional uses. Furthermore, the push for sustainable practices means that manufacturers are focusing on production methods that minimize waste and energy consumption, contributing to a more eco-friendly supply chain. This comprehensive approach, combining high-grade materials with rigorous certification processes, underpins the value proposition of CE certified metal mesh solutions in an evolving industrial ecosystem.

The Rigorous Manufacturing and Certification Journey of CE Certified Metal Fine Mesh

The production of ce certification metal fine mesh involves a meticulously controlled process, from raw material selection to final inspection, ensuring compliance with European Union safety, health, and environmental protection requirements. Primarily, this encompasses the transformation of high-grade metal sheets—often stainless steel (e.g., 304, 316L), galvanized steel, or aluminum—into precisely perforated or woven structures. The initial phase involves selecting specific material grades known for their tensile strength, corrosion resistance, and ductility, critical properties that dictate the mesh’s performance and longevity. For perforated metal, advanced punching machinery, including CNC-controlled presses, creates precise hole patterns and sizes. This process is far from simple stamping; it requires sophisticated tooling and calibration to ensure uniformity across thousands of perforations per square meter, maintaining critical dimensions like open area percentage and hole spacing.

Subsequent steps include deburring, cleaning, and surface treatment to enhance durability and specific functionalities, such as anti-corrosion properties or aesthetic finishes. Heat treatment may be applied to optimize material properties, and then rigorous quality control measures are implemented throughout the manufacturing flow. This includes dimensional verification, material composition analysis, and mechanical property testing (e.g., tensile strength, yield strength, elongation). Compliance with international standards such as ISO 9001 for quality management and ASTM standards for material specifications is non-negotiable. Furthermore, achieving CE marking for products like ce certification metal screen fabric or ce certification architectural metal mesh fabric requires adherence to specific EU directives relevant to the product's intended use, often related to construction products (CPR) or machinery safety. This comprehensive manufacturing and certification pathway guarantees that each piece of mesh not only performs as expected but also meets the highest benchmarks for safety and quality within the European market.

The lifespan of a high-quality ce certification metal fine mesh product, like ce certification hard metal mesh or ce certification thick metal mesh, can extend for decades, particularly when manufactured from premium materials such as 316L stainless steel, known for its superior resistance to chlorides and acidic environments. In industries such as petrochemical, where exposure to aggressive chemicals is common, or in metallurgy and water treatment where filtration efficiency is critical, the mesh's inherent durability translates to significant operational advantages. Its resistance to fouling and corrosion reduces maintenance downtime and replacement costs, contributing to overall energy efficiency and system longevity. For instance, in water drainage systems, the precise perforation ensures effective debris removal while preventing clogging, showcasing the practical benefits of high-quality, certified mesh.

Technical Specifications of CE Certified Metal Fine Mesh

The technical precision of ce certification metal fine mesh is critical for its functionality across various industrial and architectural applications. Key parameters include the material composition, which often specifies grades like SS304, SS316L, galvanized steel, or aluminum alloys, each chosen for specific environmental resilience and strength characteristics. For perforated variants, the hole pattern (round, square, slotted, hexagonal, custom shapes), hole size, and pitch (distance between hole centers) define the open area percentage, which directly impacts flow rate, filtration efficiency, and aesthetic appeal. Mesh count, applicable to woven varieties, describes the number of wires per linear inch, determining the fineness of filtration.

Other vital specifications include the material thickness (gauge), panel dimensions, and surface finish. For example, a ce certification black metal wire mesh might undergo a specialized coating process for enhanced corrosion resistance and aesthetic appeal, while ce certification galvanized metal wire mesh benefits from zinc coating for sacrificial protection. Products such as ce certification wire metal or ce certification fine metal mesh netting are often specified with a micron rating, indicating the smallest particle size they can effectively filter. Understanding these parameters is crucial for ensuring the mesh performs optimally in its intended application, whether it's for heavy-duty industrial separation or intricate architectural facades.

Typical Technical Parameters for CE Certified Perforated Metal Mesh

| Parameter | Description | Common Range/Value |

|---|---|---|

| Material Grades | Stainless Steel (SS), Galvanized Steel, Aluminum, Copper, Brass | SS304, SS316L, Hot-dipped Galvanized, Al-5052 |

| Hole Shape | Configuration of perforations | Round, Square, Slotted, Hexagonal, Ornamental, Custom |

| Hole Size (Diameter/Width) | Size of individual perforations | 0.5 mm - 50 mm (typically for fine mesh, 0.5mm - 5mm) |

| Pitch (Center-to-Center) | Distance from the center of one hole to the center of the next | 1.5 mm - 100 mm (relative to hole size) |

| Open Area Percentage | Ratio of open area (holes) to total sheet area | 15% - 70% (optimized for application) |

| Material Thickness | Gauge or thickness of the metal sheet | 0.3 mm - 10 mm (common for fine mesh, 0.5mm - 3mm) |

| Tensile Strength | Resistance to breaking under tension | Typically 515-690 MPa (for SS304) |

| Corrosion Resistance | Ability to withstand degradation from environment | Excellent (SS316L for chlorides) to Good (Galvanized) |

| CE Certification Standards | Applicable harmonized European standards | EN 1090 (Construction Products), relevant machinery directives |

Applications and Strategic Advantages of CE Certified Metal Fine Mesh

The versatility of ce certification metal fine mesh makes it indispensable across a multitude of industries, driven by its unique combination of mechanical strength, precise filtration capabilities, and environmental resilience. In the petrochemical sector, it serves as crucial support for catalysts in reactors, prevents particulate contamination in fluid processing, and enhances safety in grating and platforms. Its non-corrosive properties, particularly with materials like SS316L, ensure longevity in highly corrosive chemical environments, contributing significantly to process uptime and reducing maintenance overheads. For water treatment, ce certification fine metal mesh netting acts as a primary filter to remove solids, protect sensitive equipment, and improve the quality of treated water, embodying principles of energy efficiency by optimizing flow dynamics and minimizing pump strain.

Beyond heavy industry, ce certification aluminum metal mesh fabric and other forms of fine mesh are increasingly specified in architectural and design projects for facades, sunshades, interior partitions, and balustrades, offering both aesthetic appeal and functional benefits like ventilation and light diffusion. In these applications, the mesh contributes to sustainable building practices by potentially reducing energy consumption for heating, cooling, and lighting. The robust nature of ce certification metal fine mesh also makes it ideal for security barriers, EMI shielding, and acoustic panels, demonstrating its adaptability. Its inherent advantages—such as superior corrosion resistance, high strength-to-weight ratio, ease of cleaning, and long service life—translate directly into cost savings and enhanced operational safety for end-users. This broad spectrum of applications underscores the product's strategic importance in various high-stakes environments.

Choosing Your Supplier: Expertise, Customization, and Trust

Selecting the right manufacturer for ce certification metal fine mesh is a critical decision that impacts project timelines, budget, and long-term performance. A reputable supplier should demonstrate profound expertise in metal fabrication, a deep understanding of CE directives, and a proven track record of delivering consistent quality. Key factors to consider include the manufacturer's experience in the B2B sector, their commitment to R&D for innovative solutions like specialized perforation patterns or alloys, and their capacity for producing both standard and highly customized products. For instance, a client requiring specific "Other Shapes Perforated Metal Sheet" for a unique architectural facade will depend heavily on the manufacturer's engineering capabilities and flexibility.

Beyond technical prowess, robust customer support, transparent communication channels, and a clear warranty policy are hallmarks of a trustworthy partner. Evaluating a manufacturer’s adherence to global quality standards like ISO 9001 and their capability to provide material certifications (Mill Test Certificates) and performance data is essential. Furthermore, inquire about their service history, years of operation, and notable industry partnerships, which collectively affirm their authority in the field. A vendor who actively engages in problem-solving and offers comprehensive post-sales support, including installation guidance and maintenance advice, signals a true partnership approach.

Customization Solutions for Specific Needs

Tailored solutions are increasingly vital in the demanding industrial and architectural sectors. Leading manufacturers of ce certification metal fine mesh offer extensive customization options, covering everything from material type, gauge, and finish to intricate perforation designs and custom dimensions. Whether it's unique hole shapes for aesthetic purposes, specific open area percentages for optimized fluid dynamics, or specialized coatings for extreme environmental resistance, custom fabrication allows for precise alignment with project specifications. This bespoke approach minimizes waste, optimizes performance, and ensures seamless integration into complex systems, providing a competitive edge for projects requiring specialized mesh configurations beyond standard offerings. This flexibility is particularly important for applications like specialized filter media or custom decorative panels.

Real-World Impact: Application Case Studies and Trust

The practical success of ce certification metal fine mesh is best illustrated through its diverse application in significant industrial projects. For instance, in a large-scale wastewater treatment facility in Germany, high-grade ce certification metal screen fabric was deployed in primary filtration units. The client reported a 15% improvement in suspended solids removal and a 20% reduction in backwash frequency within the first year, directly attributable to the precise and durable mesh, leading to significant operational savings. Another notable case involves an architectural firm in Scandinavia utilizing custom-perforated ce certification aluminum metal mesh fabric for a building facade, achieving remarkable light diffusion and energy savings through natural ventilation, alongside providing a striking aesthetic.

Our track record spanning over two decades in the industry, coupled with collaborations with leading engineering firms and construction companies across Europe, solidifies our authority. We have consistently provided ISO 9001 certified products and ensured full traceability from raw material to finished mesh, reflecting our unwavering commitment to quality. Client feedback consistently highlights our prompt delivery, technical support, and the exceptional durability of our products, even under challenging operational conditions. For example, a major chemical plant in Belgium praised the longevity of our ce certification hard metal mesh used in their high-temperature processing units, which significantly outperformed their previous supplier's product by extending service intervals by 30%. These experiences build a foundation of trust that is paramount in B2B relationships.

Ensuring Trustworthiness: FAQs, Delivery, and Warranty

Frequently Asked Questions (FAQs)

Q: What is the lead time for custom ce certification metal fine mesh orders?

A: Standard lead times for custom orders typically range from 3-6 weeks, depending on complexity, material availability, and order volume. Expedited options are available upon request for urgent projects, subject to material readiness and production scheduling. We recommend consulting with our sales team for precise timelines tailored to your specific requirements.

Q: How do you ensure the quality and CE compliance of your metal mesh products?

A: Our quality assurance process is stringent and multi-layered. We adhere to ISO 9001 quality management systems, conduct continuous in-process inspections, and perform final product testing (e.g., dimensional accuracy, material composition, mechanical properties). CE compliance is ensured by manufacturing according to relevant harmonized EN standards and issuing Declarations of Performance (DoP) or Certificates of Conformity as required by specific EU directives like the Construction Products Regulation (CPR). All materials come with traceable mill test certificates.

Q: What kind of warranty do you offer on your ce certification metal fine mesh products?

A: We stand behind the quality of our products with a comprehensive warranty against defects in material and workmanship. The specific terms vary by product type and application, typically ranging from 1 to 5 years. Details are provided with each quotation and order confirmation. Our customer support team is always available to address any concerns or provide assistance post-delivery, ensuring long-term satisfaction and performance.

Delivery and Customer Support

We understand the importance of timely delivery in industrial projects. Our logistics team works closely with clients to coordinate efficient shipping, both domestically and internationally. We utilize established freight partners to ensure secure and prompt delivery of your ce certification metal fine mesh. Furthermore, our dedicated customer support team is available from quotation through post-installation, providing technical assistance, order updates, and expert advice. We are committed to building long-term relationships based on reliability, quality, and exceptional service.

Conclusion: The Indispensable Role of CE Certified Metal Fine Mesh

In conclusion, ce certification metal fine mesh is far more than a simple material; it is a critical engineering component that underpins safety, efficiency, and longevity across an expansive range of industrial, environmental, and architectural applications. Its compliance with rigorous CE standards ensures not only market access within the European Economic Area but also guarantees a baseline of quality, performance, and safety that is non-negotiable for discerning B2B clients. From enhancing filtration processes in water treatment and petrochemical facilities to providing durable and aesthetically pleasing elements in modern architecture, the value proposition of certified metal mesh is clear. Partnering with a manufacturer that possesses deep technical expertise, robust quality control, and a commitment to customer support ensures that projects benefit from superior materials that meet the strictest global benchmarks. Investing in high-quality, CE certified mesh is an investment in reliability, operational excellence, and peace of mind.

References

- European Commission. "CE Marking." Official Website.

- International Organization for Standardization. "ISO 9001:2015 Quality management systems – Requirements."

- ASTM International. "Standards for Metals and Metal Alloys."

- European Committee for Standardization (CEN). "EN 1090 - Execution of steel and aluminium structures."

- European Union. "Regulation (EU) No 305/2011 of the European Parliament and of the Council of 9 March 2011 laying down harmonised conditions for the marketing of construction products."

share

This is the last article

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.09,2025

-

Decorative Brass Mesh: Elevate Interiors with Timeless Elegance

NewsAug.08,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.07,2025