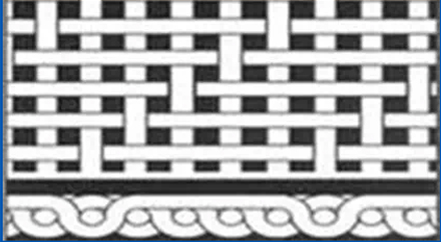

Twilled Dutch Stainless Steel Wire Mesh

Stainless Steel Dutch Woven Wire Mesh is Widely used in Neutral chloride environment,oil refining industry,petrochemical and chemical industry,chemical industry transportation pipeline,oil and gas industry,pulp and paper industry,chemical fertilizer industry,urea industry,phosphate fertilizer industry,seawater environment,energy and environment protection industry,light industry and food industry,food and pharmaceutical industry equipment,high strength structure.

Wire mesh filter cloth mainly refers to wire mesh products made with Dutch woven patterns. Our factory is an expert in Stainless Steel Dutch Woven Wire Mesh, especially custom and special type Stainless Steel Dutch Woven Wire Mesh. Welcome to CONTACT US for more information!

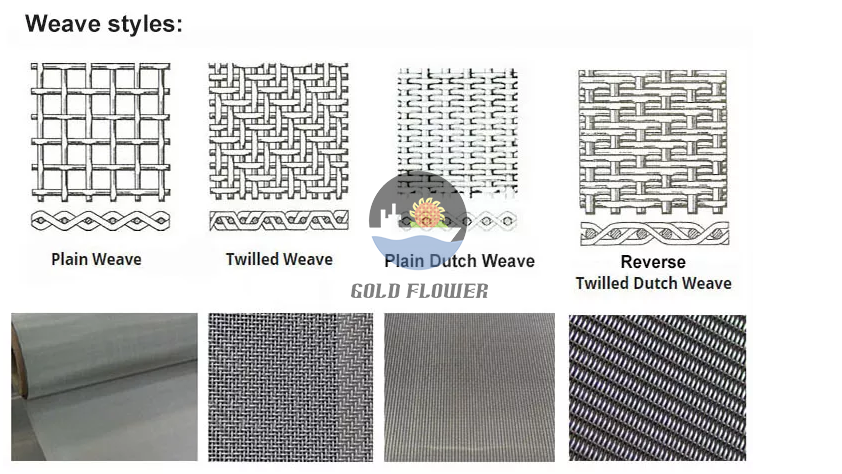

Types of Stainless Steel Dutch Woven Wire Mesh

Stainless Steel Dutch Woven Wire Mesh can be woven in both plain dutch weave and twill dutch weave. They have their own characteristics, which can be used in different applications. There is also a specially designed and applied products - reverse dutch woven wire mesh in another page, which the warp wire lies close together and has thinner wire diameter than the warp wire.

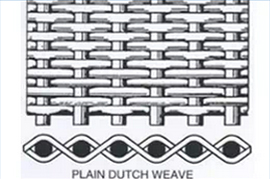

Plain weave:

Each warp wire and each weft wire passes over and under the next adjacent wire.Plain dutch weave woven wire cloth has two sizes of wire diameter. The weft wires has thinner wire diameter, which is woven tightly together to provide a tight mesh for filtering. The warp wires has coarser wire diameter, which provides strength to the woven wire cloth.

Plain dutch weave is the combination of dutch weave and plain weave. It has two sizes of wire diameters like the dutch weave. Each warp wire with coarse wire diameter passes alternately over and under one weft wire to supply high tensile strength for the netting. The weft wire with fine wire diameter alternately passes over and under one warp wire to form a fine opening for filtering.

The plain dutch weave woven wire cloth is mainly used for filtering and separating liquid and slurry products.

Advantages than the plain weave woven wire mesh

-

Greater mechanical stability.

-

Finer opening for better filtration efficiency and quality.

-

Coarser wire for higher tensile strength.

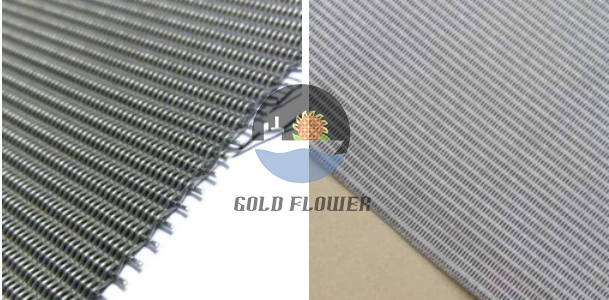

Twill dutch weave

It is the extension of the twill weave. Each warp wire and each weft wire passes over and under the next two adjacent complementary wires, which is similar as twill weave. The wire diameter of warp wire is larger than weft wire. The mesh count in the weft direction is greater than the warp direction. Dutch twill weave enables the weft wires to be woven more densely and much smaller aperture sizes can be achieved.

Twill dutch woven wire mesh is the combination of dutch weave and twill weave. The weft wires passes alternately over and under two warp wire forming a finer mesh in the warp direction and the warp wires forms a coarser mesh in the warp direction in the same weaving.Twill dutch woven wire mesh is superior to the twill woven wire cloth because of the finer openings.

Twill dutch weave is capable of supporting greater loads than the dutch weave. It has finer openings than the twilled weave. It can support greater loads than the dutch weave woven wire mesh. It is used for filtering heavy materials.

Advantages than the twill weave woven wire mesh

-

Better filtering performance.

-

Higher tensile strength.

-

Can be used for filtering ultra-fine products.

-

Much more stable structure.

Applications of dutch weave woven wire mesh

-

Dutch weave woven wire mesh is mainly used for filtering. It provides superior filtration capabilities for a wide range of areas applications.

-

Aerospace.

-

Petrochemical.

-

Pharmaceutical.

-

Mining.

-

Waste water.

-

According to the material of filtering, the plain dutch and twill dutch can be used in different applications.

-

The plain dutch weave woven wire mesh is mainly used for filtering and separating liquid and slurry products.

-

The twill dutch weave woven wire mesh is used for filtering heavy materials.

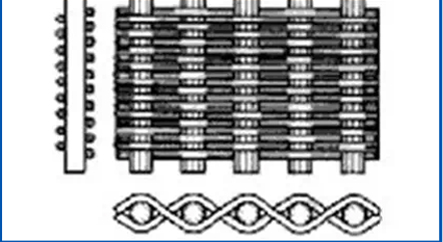

Reverse dutch weave woven wire cloth

Reverse dutch weave woven wire cloth has finer wire diameter in warp wire and coarser wire diameter in weft wire. and the mesh count in the warp wire is larger than the weft wire.

Woven wire mesh with various materials and weaving types has a wide range of applications, which the most common is filtration. Detail applications are in the below.

· Industrial filtration. Industrial filtration need accurate and effective filtration. We can supply the filter discs and sintered filter mesh for high efficiency and fine filtering.

· Food filtration. has various types for food filtering and sieving, including water, oil and powder.

· Hops and hot breaks filtration. The bazooka screen is mainly used in the kettles, tuns and other containers to filter hops and hot breaks.

Specifications Of Stainless Steel Dutch Woven Wire Mesh:

Stainless Steel Dutch Woven Wire Mesh.

Material: Aisi321, 302, 304, 304L, 316 and 316L stainless steel wire, black wire, Al5Cr23, Ni80Cr20, Ni60Cr15 and etc.

Weave: plain dutch, twilled dutch, reverse, five heddle weave.

Characteristics: acid resisting, alkali resisting, heat resisting and wear resisting.

Application: used for industries of mining, oil, chemical, food, phamaceutical, machine making, scientific research, aviation, etc.

Stainless Steel Dutch Woven Wire Mesh can be further divided into mainly four types according to weaving patterns:

-

Wire Mesh Filter Cloth Dutch Plain Woven.

-

Wire Mesh Filter Cloth Dutch Twill Woven.

-

Wire Mesh Filter Cloth Reverse Dutch Woven.

-

Wire Mesh Filter Cloth Five-Heddle Woven.

| Plain Dutch Woven Wire Cloth | |||

| Mesh/Inch Warp x Weft |

Wire Diameter mm |

Weight kgs/m2 |

Filtering valueμm |

| 7 x 50 | 0.70 x 0.54 | 4.50 | 315 |

| 8 x 60 | 0.55 x 0.45 | 3.64 | 280 |

| 12 x 64 | 0.58 x 0.42 | 3.80 | 180 |

| 12 x 90 | 0.45x 0.30 | 2.60 | 160 |

| 14 x 88 | 0.50 x 0.33 | 2.81 | 150 |

| 14 x 100 | 0.40 x 0.28 | 2.52 | 140 |

| 18 x 100 | 0.40 x 0.28 | 2.61 | 130 |

| 24 x 110 | 0.35 x 0.25 | 2.45 | 115 |

| 25 x 140 | 0.30 x 0.20 | 1.96 | 100 |

| 30 x 150 | 0.23 x 0.18 | 1.61 | 95 |

| 30 x 160 | 0.23 x 0.18 | 1.69 | 90 |

| 40 x 200 | 0.18 x 0.14 | 1.30 | 75 |

| 45 x 220 | 0.18 x 0.125 | 1.22 | 56 |

| 50 x 250 | 0.14 x 0.11 | 1.00 | 60 |

| 50 x 280 | 0.14 x 0.10 | 0.84 | 45 |

| 60 x 300 | 0.14 x 0.09 | 0.80 | 40 |

| 65 x 320 | 0.12 x 0.085 | 0.75 | 36 |

| 70 x 350 | 0.11 x 0.08 | 0.70 | 34 |

| 70 x 400 | 0.11 x 0.07 | 0.68 | 32 |

| 80 x 400 | 0.12 x 0.07 | 0.55 | 35 |

| Twill Dutch Woven Wire Cloth | ||||

| Mesh/Inch Warp x Weft |

Wire Diameter mm |

Weight kgs/m2 |

Filtering valueμm μm |

|

| 20 x 250 | 0.28 x 0.20 | 6.55 | 87 | |

| 30 x 250 | 0.25 x 0.20 | 2.96 | 70 | |

| 80 x 700 | 0.10 x 0.08 | 1.32 | 25 | |

| 80 x 780 | 0.11 x 0.07 | 1.19 | 27 | |

| 100 x 780 | 0.10 x 0.07 | 1.20 | 25 | |

| 100 x 900 | 0.10 x 0.60 | 1.06 | 22 | |

| 100 x 780 | 0.10 x 0.70 | 1.21 | 24 | |

| 120 x 400 | 0.10 x 0.06 | 0.66 | 40 | |

| 120 x 600 | 0.10 x 0.06 | 0.84 | 30 | |

| 120 x 1100 | 0.08 x 0.05 | 0.88 | 18 | |

| 165 x 800 | 0.07 x 0.05 | 0.70 | 15 | |

| 165 x 1200 | 0.07 x 0.04 | 0.68 | 19 | |

| 165 x 1400 | 0.07 x 0.04 | 0.76 | 14 | |

| 200 x 600 | 0.06 x 0.045 | 0.48 | 20 | |

| 200 x 900 | 0.05 x 0.035 | 0.40 | 23 | |

| 200 x 1400 | 0.07 x 0.04 | 0.80 | 10 | |

| 250 x 2000 | 0.04 x 0.027 | 0.46 | 8 | |

| 280 x 2200 | 0.035 x 0.025 | 0.42 | 6.3 | |

| 320 x 2300 | 0.033 x 0.024 | 0.41 | 5 | |

| 325 x 2300 | 0.035 x 0.025 | 0.45 | 5 | |

| 400 x 2800 | 0.025 x 0.020 | 0.36 | 3 | |

| 500 x 3500 | 0.025 x 0.015 | 0.30 | 5 |

|

| Reverse Dutch Weave Wire Cloth | ||||

| Mesh/Inch Warp x Weft |

Wire Diameter Warp x Weft mm |

Wire Diameter Warp x Weft inch |

Absolute Filter rating μm |

|

| 63 x 18 | 0.40 x 0.60 | 0.0157 x 0.0236 | 220 | |

| 107 x 20 | 0.24 x 0.60 | 0.0094 x 0.0236 | 210 | |

| 130 x 35 | 0.20 x 0.40 | 0.0079 x 0.0157 | 80 | |

| 132 x 16 | 0.24 x 0.60 | 0.0094 x 0.0236 | 200 | |

| 132 x 32 | 0.20 x 0.40 | 0.0079 x 0.0157 | 105 | |

| 140 x 40 | 0.19 x 0.38 | 0.0075 x 0.015 | 100 | |

| 170 x 40 | 0.20 x 0.45 | 0.0079 x 0.0177 | 130 | |

| 180 x 120 | 0.088 x 0.10 | 0.0035 x 0.004 | 75 | |

| 200 x 120 | 0.08x 0.10 | 0.0031 x 0.004 | 70 | |

| 175 x 40 | 0.15 x 0.38 | 0.0079 x 0.0157 | 70 | |

| 175 x 50 | 0.15 x 0.30 | 0.0059 x 0.012 | 60 | |

| 290 x 75 | 0.09 x 0.20 | 0.0035 x 0.0079 | 55 | |

| 600 x 100 | 0.04x 0.14 | 0.0157 x 0.0055 | 25 | |

| 615 x 130 | 0.04 x 0.13 | 0.0157 x 0.0051 | 22 | |

| 615 x 102 | 0.04x 0.16 | 0.0157 x 0.0063 | 42 | |

| 625 x 133 | 0.04 x 0.13 | 0.0157 x 0.0051 | 17 | |

| 720 x 150 | 0.036 x 0.10 | 0.0014 x 0.0039 | 17 | |

| 850 x 155 | 0.03 x 0.10 | 0.0012 x 0.004 | 10 | |

| Five-heddle Dutch Weave Wire Cloth | |||||

| Mesh/Inch Warp x Weft |

Wire Diameter mm |

Aperture(mm)Warp x Weft | Open Area | Weightkgs/m2 | |

| 108 x 59 | 0.160 | 0.075 x 0.271 | 20 | 1.07 | |

| 110 x 60 | 0.160 | 0.071 x 0.263 | 19 | 1.09 | |

| 38 x 38 | 0.150 | 0.518 x 0.518 | 60 | 0.43 | |

-

Plain dutch weave

-

Twilled dutch weave

-

Reverse dutch waeve 1

-

Reverse dutch weave 2

-

Five-heddle weave

-

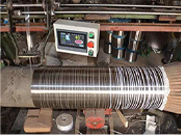

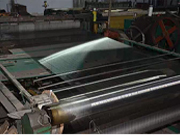

Material Production

-

Diameter Inspect

-

Tension Test

-

Material Check

-

Material Check

-

Trimming Edge

-

Length and Width Inspect

-

Hole Size Test

-

Mesh Inspect

-

Weaving

-

Intension Test

-

Diameter Inspect

-

Thickness Inspect

-

Role size Inspect

-

Mesh Test

-

Length and Width Check

-

Trimming Edge

-

Mesh Inspect

With the most perfect way to protect your cargo security

-

1

Cardboard Tube

-

2

Thick Paper Board

-

3

Thick Plastic Cloth

-

4

Perfect Wooden Case

-

5

Thick Plastic Bubble Film

-

6

Excellent Cover

-

7

Steel Strap Fix

-

8

Package Check

-

9

Container Transport