Grain industry filter Woven Mesh

Grain industry filter Woven Mesh

The Grain Industry Filter Woven Mesh is a high-quality filtering material designed specifically for use in the grain industry. Made from durable and long-lasting materials, this mesh is able to withstand the rigors of the grain processing environment while effectively filtering out unwanted contaminants. The mesh is designed to be easy to clean and maintain, ensuring that it stays in optimal condition for as long as possible.

Whether you're looking to improve the quality of your grain products or simply want to ensure that your equipment is operating at its best, the Grain Industry Filter Woven Mesh is an excellent choice. As an experienced Wire Mesh manufacturer, we sell the best and various Dutch Woven Wire Cloth. If you are interested in our grain industry filter woven mesh, feel free to contact us!

Advantages

There are several advantages to using the Grain Industry Filter Woven Mesh:

1. Durability: The mesh is made from high-quality materials that are able to withstand the harsh conditions found in the grain industry.

2. Effectiveness: The mesh is designed to filter out unwanted contaminants, improving the overall quality of your grain products.

3. Easy to clean and maintain: The mesh is easy to clean and maintain, ensuring that it stays in optimal condition for as long as possible.

4. Cost-effective: Using the Grain Industry Filter Woven Mesh can save you money in the long run by reducing the need for costly repairs and maintenance.

5. Improved equipment performance: By keeping your equipment free of contaminants, the Grain Industry Filter Woven Mesh can help to improve its overall performance and extend its lifespan.

We manufacture and export kinds of grain industry filter woven mesh

The main production of woven wire mesh is weaving. Weaving type has various types, including the plain weave, twill weave, dutch weave and reverse dutch weave.

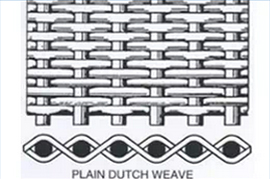

Plain weave

Each warp wire and each weft wire passes over and under the next adjacent wire.

Plain dutch weave woven wire cloth has two sizes of wire diameter. The weft wires has thinner wire diameter, which is woven tightly together to provide a tight mesh for filtering. The warp wires has coarser wire diameter, which provides strength to the woven wire cloth.

Characteristics

1. Zero aperture.

2. It is solid than square and rectangular mesh.

3. The open area is relatively higher than the other weave.

Application

Plain dutch woven wire cloth is used for separation of solids and clear filtration of liquids, as in the cleaning of fuels or hydraulic liquids, or in water treatment in chemical, mining industry.

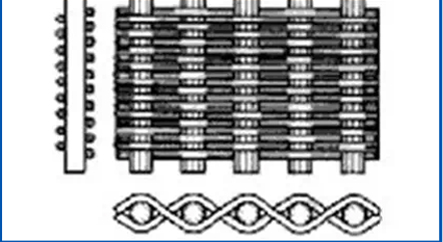

Twill dutch weave

It is the extension of the twill weave. Each warp wire and each weft wire passes over and under the next two adjacent complementary wires, which is similar as twill weave. The wire diameter of warp wire is larger than weft wire. The mesh count in the weft direction is greater than the warp direction. Dutch twill weave enables the weft wires to be woven more densely and much smaller aperture sizes can be achieved.

Twill dutch weave is capable of supporting greater loads than the dutch weave. It has finer openings than the twilled weave. It is used for filtering heavy materials.

Characteristics

1. Zero aperture.

2. Light-proof woven.

3. High resistance due to tight wire position.

4. Extreme low absolute grade of fineness (down to 5 6 μm).

5. Heat resistance.

6. Acid and alkali resistance.

7. Corrosion and rust resistance.

Application

It is the finest filtration in hydraulic systems, especially for critical applications, such as aero-space and fuel.

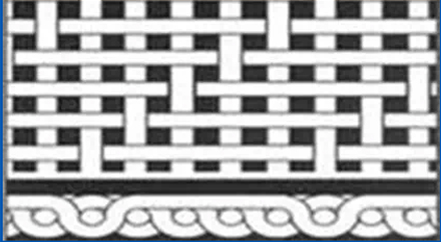

Reverse dutch weave woven wire cloth

Reverse dutch weave woven wire cloth has finer wire diameter in warp wire and coarser wire diameter in weft wire. and the mesh count in the warp wire is larger than the weft wire.

Application

It is the basic filter materials for pharmacy, food, medicine, chemical and other industries.

| Plain Dutch Woven Wire Cloth | |||

| Mesh/Inch Warp x Weft |

Wire Diameter mm |

Weight kgs/m2 |

Filtering valueμm |

| 7 x 50 | 0.70 x 0.54 | 4.50 | 315 |

| 8 x 60 | 0.55 x 0.45 | 3.64 | 280 |

| 12 x 64 | 0.58 x 0.42 | 3.80 | 180 |

| 12 x 90 | 0.45x 0.30 | 2.60 | 160 |

| 14 x 88 | 0.50 x 0.33 | 2.81 | 150 |

| 14 x 100 | 0.40 x 0.28 | 2.52 | 140 |

| 18 x 100 | 0.40 x 0.28 | 2.61 | 130 |

| 24 x 110 | 0.35 x 0.25 | 2.45 | 115 |

| 25 x 140 | 0.30 x 0.20 | 1.96 | 100 |

| 30 x 150 | 0.23 x 0.18 | 1.61 | 95 |

| 30 x 160 | 0.23 x 0.18 | 1.69 | 90 |

| 40 x 200 | 0.18 x 0.14 | 1.30 | 75 |

| 45 x 220 | 0.18 x 0.125 | 1.22 | 56 |

| 50 x 250 | 0.14 x 0.11 | 1.00 | 60 |

| 50 x 280 | 0.14 x 0.10 | 0.84 | 45 |

| 60 x 300 | 0.14 x 0.09 | 0.80 | 40 |

| 65 x 320 | 0.12 x 0.085 | 0.75 | 36 |

| 70 x 350 | 0.11 x 0.08 | 0.70 | 34 |

| 70 x 400 | 0.11 x 0.07 | 0.68 | 32 |

| 80 x 400 | 0.12 x 0.07 | 0.55 | 35 |

| Twill Dutch Woven Wire Cloth | |||

| Mesh/Inch Warp x Weft |

Wire Diameter mm |

Weight kgs/m2 |

Filtering valueμm μm |

| 20 x 250 | 0.28 x 0.20 | 6.55 | 87 |

| 30 x 250 | 0.25 x 0.20 | 2.96 | 70 |

| 80 x 700 | 0.10 x 0.08 | 1.32 | 25 |

| 80 x 780 | 0.11 x 0.07 | 1.19 | 27 |

| 100 x 780 | 0.10 x 0.07 | 1.20 | 25 |

| 100 x 900 | 0.10 x 0.60 | 1.06 | 22 |

| 100 x 780 | 0.10 x 0.70 | 1.21 | 24 |

| 120 x 400 | 0.10 x 0.06 | 0.66 | 40 |

| 120 x 600 | 0.10 x 0.06 | 0.84 | 30 |

| 120 x 1100 | 0.08 x 0.05 | 0.88 | 18 |

| 165 x 800 | 0.07 x 0.05 | 0.70 | 15 |

| 165 x 1200 | 0.07 x 0.04 | 0.68 | 19 |

| 165 x 1400 | 0.07 x 0.04 | 0.76 | 14 |

| 200 x 600 | 0.06 x 0.045 | 0.48 | 20 |

| 200 x 900 | 0.05 x 0.035 | 0.40 | 23 |

| 200 x 1400 | 0.07 x 0.04 | 0.80 | 10 |

| 250 x 2000 | 0.04 x 0.027 | 0.46 | 8 |

| 280 x 2200 | 0.035 x 0.025 | 0.42 | 6.3 |

| 320 x 2300 | 0.033 x 0.024 | 0.41 | 5 |

| 325 x 2300 | 0.035 x 0.025 | 0.45 | 5 |

| 400 x 2800 | 0.025 x 0.020 | 0.36 | 3 |

| 500 x 3500 | 0.025 x 0.015 | 0.30 | 5 |

| Reverse Dutch Weave Wire Cloth | |||

| Mesh/Inch Warp x Weft |

Wire Diameter Warp x Weft mm |

Wire Diameter Warp x Weft inch |

Absolute Filter rating μm |

| 63 x 18 | 0.40 x 0.60 | 0.0157 x 0.0236 | 220 |

| 107 x 20 | 0.24 x 0.60 | 0.0094 x 0.0236 | 210 |

| 130 x 35 | 0.20 x 0.40 | 0.0079 x 0.0157 | 80 |

| 132 x 16 | 0.24 x 0.60 | 0.0094 x 0.0236 | 200 |

| 132 x 32 | 0.20 x 0.40 | 0.0079 x 0.0157 | 105 |

| 140 x 40 | 0.19 x 0.38 | 0.0075 x 0.015 | 100 |

| 170 x 40 | 0.20 x 0.45 | 0.0079 x 0.0177 | 130 |

| 180 x 120 | 0.088 x 0.10 | 0.0035 x 0.004 | 75 |

| 200 x 120 | 0.08x 0.10 | 0.0031 x 0.004 | 70 |

| 175 x 40 | 0.15 x 0.38 | 0.0079 x 0.0157 | 70 |

| 175 x 50 | 0.15 x 0.30 | 0.0059 x 0.012 | 60 |

| 290 x 75 | 0.09 x 0.20 | 0.0035 x 0.0079 | 55 |

| 600 x 100 | 0.04x 0.14 | 0.0157 x 0.0055 | 25 |

| 615 x 130 | 0.04 x 0.13 | 0.0157 x 0.0051 | 22 |

| 615 x 102 | 0.04x 0.16 | 0.0157 x 0.0063 | 42 |

| 625 x 133 | 0.04 x 0.13 | 0.0157 x 0.0051 | 17 |

| 720 x 150 | 0.036 x 0.10 | 0.0014 x 0.0039 | 17 |

| 850 x 155 | 0.03 x 0.10 | 0.0012 x 0.004 | 10 |

| Five-heddle Dutch Weave Wire Cloth | ||||

| Mesh/Inch Warp x Weft |

Wire Diameter mm |

Aperture(mm)Warp x Weft | Open Area | Weightkgs/m2 |

| 108 x 59 | 0.160 | 0.075 x 0.271 | 20 | 1.07 |

| 110 x 60 | 0.160 | 0.071 x 0.263 | 19 | 1.09 |

| 38 x 38 | 0.150 | 0.518 x 0.518 | 60 | 0.43 |

We look forward to working with you!

ANPING GOLDFLOWER WIRE MESH FACTORY--predecessor of Anping Sanping Wire Mesh Factory, manufacture and export wire and wire mesh products: stainless steel, Ni, Ti and etc. Today we are one of the famous factories in stainless steel market of the world! We are committed to providing you with the best products and services! If you need anything, please feel free to contact us!

-

Plain dutch weave

-

Twilled dutch weave

-

Reverse dutch waeve 1

-

Reverse dutch weave 2

-

Five-heddle weave

-

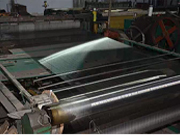

Material Production

-

Diameter Inspect

-

Tension Test

-

Material Check

-

Material Check

-

Trimming Edge

-

Length and Width Inspect

-

Hole Size Test

-

Mesh Inspect

-

Weaving

-

Intension Test

-

Diameter Inspect

-

Thickness Inspect

-

Role size Inspect

-

Mesh Test

-

Length and Width Check

-

Trimming Edge

-

Mesh Inspect

With the most perfect way to protect your cargo security

-

1

Cardboard Tube

-

2

Thick Paper Board

-

3

Thick Plastic Cloth

-

4

Perfect Wooden Case

-

5

Thick Plastic Bubble Film

-

6

Excellent Cover

-

7

Steel Strap Fix

-

8

Package Check

-

9

Container Transport